EVERY MOTORSPORTS ENTHUSIAST SHOULD BE FAMILIAR with the names Subaru and Cosworth. Both brands are synonymous with a strong racing heritage and tradition in both rally racing and Formula 1. A combination of the two companies’ best wares might make for an ideal platform that could terrorize the countryside with excess power and tremendous handling abilities. Indonesian resident and shop owner Chunkie Chandra has not only spotted one of these creatures, but has reigned one in to do with as he pleases.

Text by Kevin Lee // Photos by Muhammad Balbed

ON-ROAD EXCURSIONS

With a sound knowledge of both Subaru and Cosworth’s accomplishments, Chandra was certain that he had picked the right car when he bought his WRX in 2008. His intention was to attack the mountainous winding expressways in Lampung, South of Sumatra between his home and his shop, Racetech Performance. According to him, there is nothing that handles thatjob better than Subaru’s Asymmetric All-Wheel Drive system and low-mount, turbocharged boxer setup. Still, the factory turbocharged 2.0-liter engine didn’t have quite the power Chandra was looking for so a powerplant metamorphosis was in order.

HEAVYWEIGHT BOXER

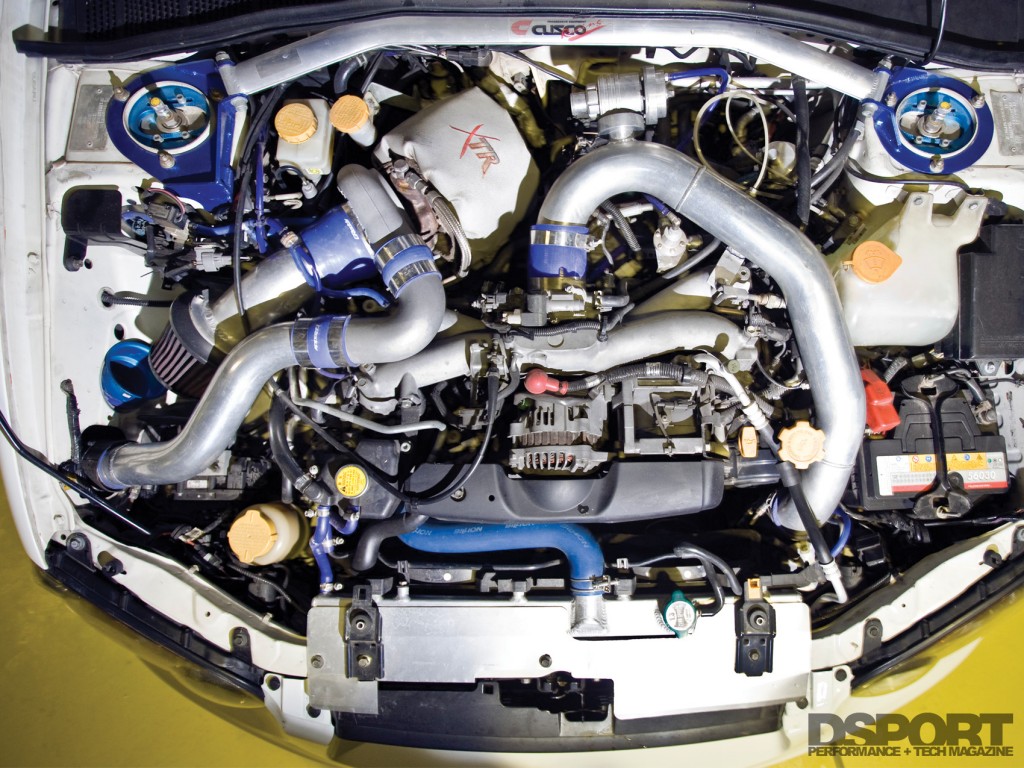

Chandra’s first order of business was a displacement increase that he accomplished by swapping out the EJ20 bottom-end with a new EJ257 block. He supplemented the extra half-liter of displacement by refreshing the rotating assembly with newer Cosworth components. A set of Cosworth slugs now occupies the opposing cylinder banks, dropping compression down to 8.5 to-1. A quartet of Cosworth rods connects to the factory EJ257 crankshaft to complete the remainder of the rotating assembly. Due to the horizontal orientation of the cylinder banks, increased crankcase pressures and spirited driving can easily create an oil starvation condition. As such, Chandra installed a Cosworth baffle plate kit that directs retur ning oil away from the crankshaft and prevents oil from re-entering the upper crankcase. To reduce the risk of “head lift” under increased cylinder pressures and boost levels, Chandra threaded ARP 14mm head studs through each cylinder head to clamp down on the Cosworth MLS head gaskets. [pullquote]

The interior sports a pair of BRIDE seats up front and factory seats wrapped in BRIDE fabric in the rear.

[/pullquote]

HEAD SHOTS

Up top, Chandra installed a set of Cosworth camshafts into the cylinder heads to improve combustion-cycle intake and exhaust gas flow. To further increase the intake charge volume, a GReddy TD06 25G turbocharger stands in for the factory unit. Chandra selected this particular turbocharger to provide higher potential boost levels while maintaining the spooling-speeds required to properly manhandle the curving countryside. An HKS frontmounted intercooler handles charge-air cooling duties. On the other side of the A/F equation, Chandra supplemented the fuel system with a set of Power Enterprise 800cc/min injectors. A Walbro in-tank fuel pump feeds the injectors the required volume of 95-octane pump gas while a SARD fuel-pressure regulator modifies delivery according to boost pressures.