The idea of an automatic drag car seems so “domestic” to most import enthusiasts. After all, when was the last time you saw an automatic Civic, RX7 or Supra scorching the 1320? Of course, there have been automatic conversions adopted by the Supra community, LS swapped imports, and the 1G/2G DSM crowds. Some of these conversions have proven to outperform and, in some cases, outlast their three-pedaled cousins on the drag strip.

Text by Richard Fong // Photos by Jun Chen and Richard Fong

Commemorating Racing

Commemorating Racing

Buschur Racing has celebrated over 25 years of racing and tuning Mitsubishis and, more recently, Nissan’s R35 GT-R. Not long after opening his shop, the president of Buschur Racing (BR), David Buschur, got together with some friends for a private day at the drag strip. This gathering grew into the annual event we all know as “The Shootout.” 2012 would mark the twentieth running of The Shootout, and David decided to build a commemorative car to race at the event in tribute to his company’s racing roots. He chose a ground up all-wheel drive drag car build based on a first generation (1G) Diamond Star Motors (DSM). Of his decision David stated, “I don’t believe that there is a better production four cylinder engine on the planet than a 4G63. This engine, combined with the available all-wheel driveline gave the DSMs a huge advantage back in the early 90s when the ‘import racing’ scene was in its infancy. To me, the performance, styling, aero and interior were ahead of their time.”

David purchased this 1991 Eagle Talon TSi early in 2012. He was under the impression that the car was already clean and built with quality components, which would give him a little bit of a head start on the project. Unfortunately, when the car arrived, it was a different story. In David’s words, “We ended up with a basket case of poorly put together scrap.” Fortunately, the chassis was rust free, which was a major concern. Everything else could be made right. With a quickly approaching deadline to contend with, the team got straight to work.

Body Building

The Talon was dismantled to the last nut and bolt and then cleaned up, before the chassis took a short trip to Gary Reese Chassis in Elyria, Ohio for some fabrication work. There, the Talon was reinforced with a custom cage, parachute mount, mirror delete plates and a custom rear sub frame. Once completed, the shell was sent to Elvin Rivera to be prepped and sprayed. Rivera expertly cleaned up the shell of all imperfections before spraying the Talon in a frost white finish. When the chassis returned to Wakeman, the Talon’s exterior looked as glossy smooth as porcelain.

The Talon was dismantled to the last nut and bolt and then cleaned up, before the chassis took a short trip to Gary Reese Chassis in Elyria, Ohio for some fabrication work. There, the Talon was reinforced with a custom cage, parachute mount, mirror delete plates and a custom rear sub frame. Once completed, the shell was sent to Elvin Rivera to be prepped and sprayed. Rivera expertly cleaned up the shell of all imperfections before spraying the Talon in a frost white finish. When the chassis returned to Wakeman, the Talon’s exterior looked as glossy smooth as porcelain.

Team Building Exercise

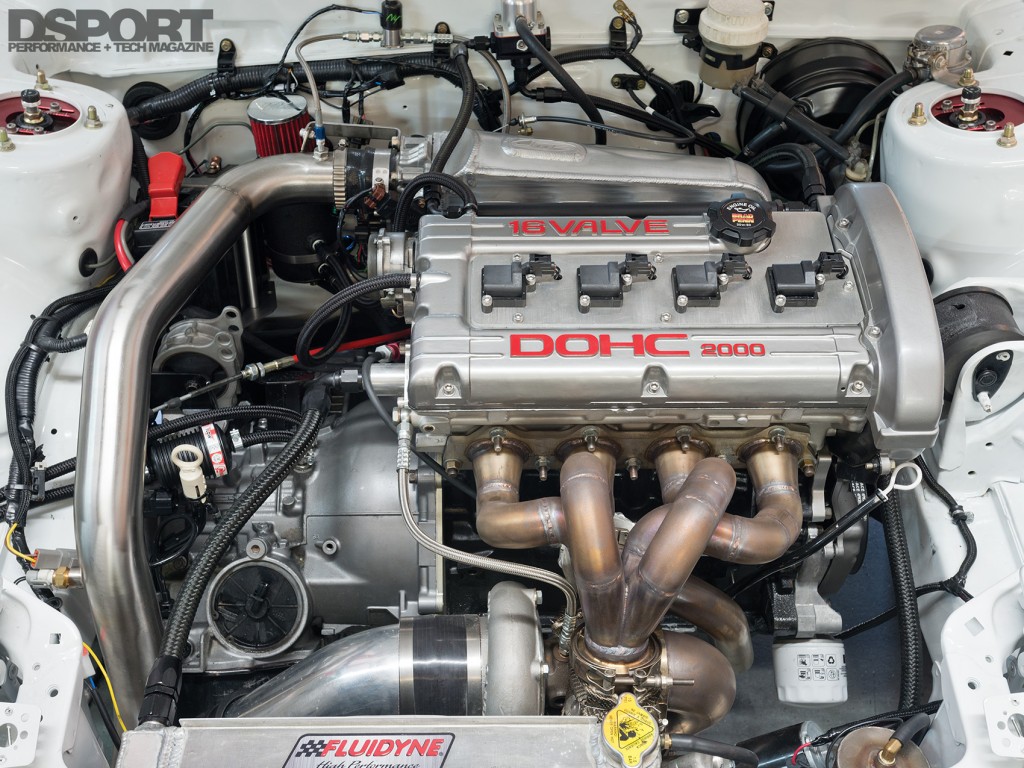

While the chassis was at fabrication and paint, the BR crew went to work on the powertrain and driveline. David focused specifically on the 4G63 engine. Since this engine would spend its life at the drag strip, David filled the water jackets with Hard Blok, reinforcing the cylinders and preparing them for higher boost and cylinder pressures. David then filled the cylinders with high-compression 10.5:1 Wiseco HD pistons linked to the crankshaft by way of Manley 300m forged connecting rods.

Up top, it was necessary to improve the volumetric efficiency of the cylinder head. Thus, BR’s Ted Harrison ported and polished the cylinder head before installing a complete Supertech valvetrain with +0.5mm- oversized valves. Once the head was reunited with the strengthened 4G63 engine, David chose a set of BR BF 272-degree camshafts to provide a higher lift and longer duration to the valves.

Pumped Up Powertrain

With an optimized longblock assembly in place, it was time to evaluate power-adding solutions. To start, a BR manifold positions and feeds exhaust gasses into the V-band inlet of a Forced Performance HTA86 turbocharger. A BR 3-inch downpipe and exhaust direct the gasses leaving the turbine housing to the rear of the chassis and through an SD muffler on the way to the atmosphere. The turbocharger’s compressor forces ambient air through a BR front-mount Race intercooler to exchange heat with the atmosphere. From the intercooler, the chilled air charge flows through an EVO throttle body before filling a JMF custom intake manifold. From the manifold, the air charge is distributed equally to the intake ports. At each intake port, a Fuel Injector Clinic 2,150cc/min injector saturates the compressed air entering the cylinders with E98 fuel.