When cars get old, things begin to rattle, vibrate and become loose. Most people looking to improve the suspension of their vehicle seek out performance upgrades such as a set of adjustable coilovers, sway bars and even adjustable arms. Few people realize that trying to improve a vehicle’s suspension without addressing worn out rubber bushings is pretty much pointless. However, the reality is that when bushings deflect under high-load braking and cornering, dynamic changes in camber, caster or toe will result. These changes often reduce the size of a tire’s contact patch. In the case of cars that have endured hundreds of thousands of miles of abuse, the factory rubber bushings simply can’t keep things straight.

Text by Jun Chen // Photos by Jun Chen and courtesy of Energy Suspension

DSPORT Issue #146

WORN AND TORN

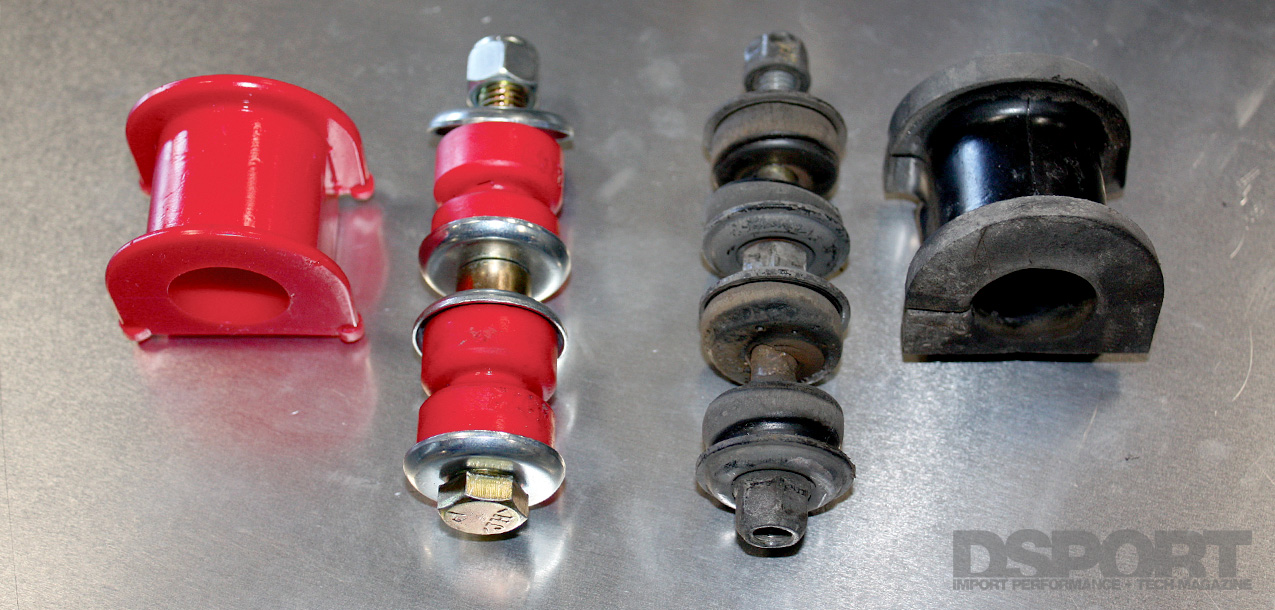

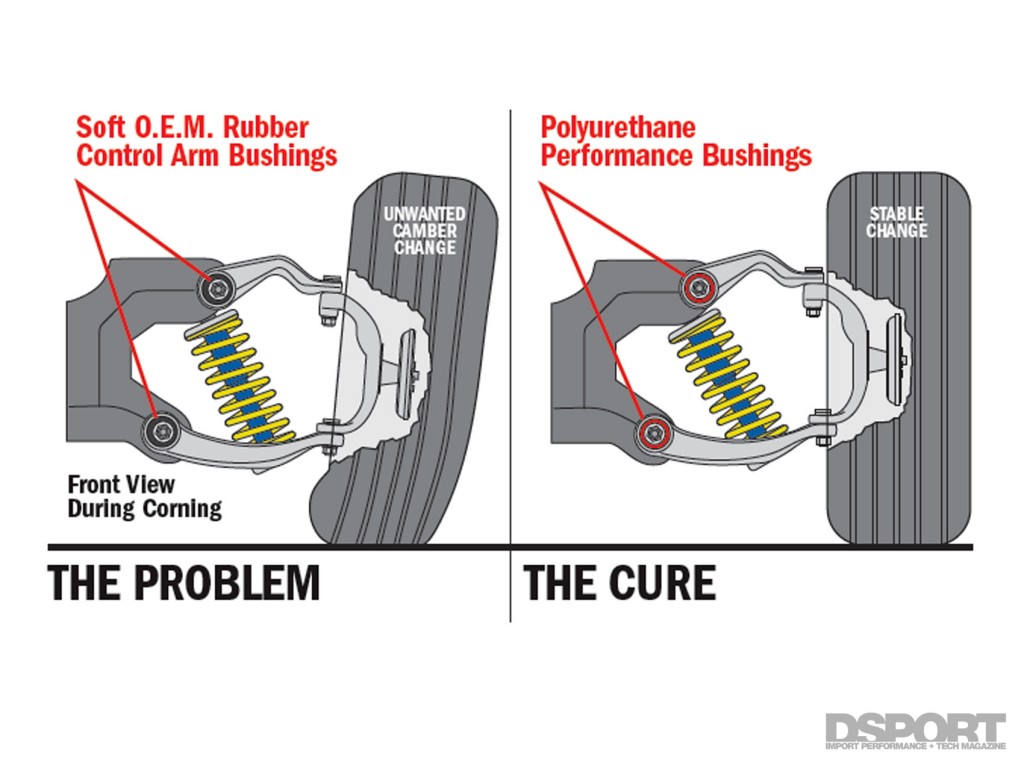

From the factory, natural rubber works great as an absorption material for vibrations and other road imperfections. However, this material is vulnerable to oils, ozone and extreme temperatures. When exposed to heat and ozone in our atmosphere, the rubber will harden and crack. Oil leaks from the engine, transmission or other areas can cause bushings to literally disintegrate. Over years and extended mileage, these wear factors will ultimately cause rubber bushings to deteriorate and fail. In addition to wear concerns, the soft nature of rubber bushings introduces play into the suspension system. When the bushings face high-load conditions, the rubber can compress or stretch, causing dynamic camber, caster or toe changes. These changes can adversely affect a vehicle’s handling characteristics. Quite simply, worn rubber bushings will allow alignment angles to shift out of spec. Both the softness and lack of durability of rubber bushings make them a not-so-solid choice for a performance suspension setup.

From the factory, natural rubber works great as an absorption material for vibrations and other road imperfections. However, this material is vulnerable to oils, ozone and extreme temperatures. When exposed to heat and ozone in our atmosphere, the rubber will harden and crack. Oil leaks from the engine, transmission or other areas can cause bushings to literally disintegrate. Over years and extended mileage, these wear factors will ultimately cause rubber bushings to deteriorate and fail. In addition to wear concerns, the soft nature of rubber bushings introduces play into the suspension system. When the bushings face high-load conditions, the rubber can compress or stretch, causing dynamic camber, caster or toe changes. These changes can adversely affect a vehicle’s handling characteristics. Quite simply, worn rubber bushings will allow alignment angles to shift out of spec. Both the softness and lack of durability of rubber bushings make them a not-so-solid choice for a performance suspension setup.

To address the shortcomings of rubber bushings, Energy Suspension set out to develop a material that would last longer and keep the suspension parts in line for years to come. Addressing the two main weak points of rubber, Energy’s proprietary HYPER-FLEX polyurethane material increases the longevity of the bushing and greatly reduces the chance for dynamic alignment changes under high-load circumstances. The HYPER-FLEX material is impervious to oil and grease. Compared to natural rubber, polyurethane features a higher durometer (firmess) material that can help improve stability and control under high performance driving conditions.

To address the shortcomings of rubber bushings, Energy Suspension set out to develop a material that would last longer and keep the suspension parts in line for years to come. Addressing the two main weak points of rubber, Energy’s proprietary HYPER-FLEX polyurethane material increases the longevity of the bushing and greatly reduces the chance for dynamic alignment changes under high-load circumstances. The HYPER-FLEX material is impervious to oil and grease. Compared to natural rubber, polyurethane features a higher durometer (firmess) material that can help improve stability and control under high performance driving conditions.

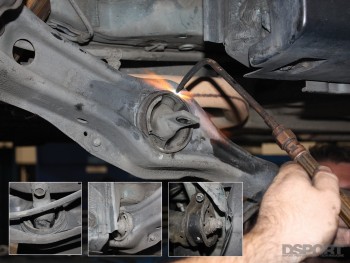

[pullquote]THE FACTORY RUBBER BUSHINGS SHOWED VARIOUS DEGREES OF CRACKING AND TEARING[/pullquote]On Jeren’s new daily driver, a 1996 Acura Integra, the previous owner had already fitted a set of aftermarket coilovers and set them to a very low ride height. After a close inspection of the suspension, it became clear that many of the factory suspension bushings were beyond due for replacement. Approaching twenty years and over 150,000 miles, the factory rubber bushings showed various degrees of cracking and tearing. This vehicle provided us the perfect opportunity to increase the performance of his vehicle with a polyurethane bushing solution.