The power potential of an engine platform increases as you increase the redline potential of the engine. However, one would assume that doubling the engine RPM doubles the load on all of the reciprocating components. In fact, the actual relationship between engine speed and load is as follows. The load on the engine increases as the square of the engine speed increase. For example, the physical loads seen on the rotating assembly at 8,000 RPM are actually four times the physical load of 4,000 RPM. Factor in the additional stresses and loads from doubling or tripling the cylinder pressures and it’s easy to see that the critical fasteners in a performance engine don’t have an easy life.

By Michael Ferrara

DSPORT Issue #105

Small Investment for Big Protection

Purchasing quality performance fasteners is “cheap insurance” for your engine. The added reliability that can be obtained by using performance bolts easily outweighs the additional cost involved in the upgrade. The use of stronger rod bolts, main bolts/studs and head bolts/studs have all allowed more horsepower to be realized.

Cosworth’s H11 tool steel head studs are available for a limited number of applications.

Cosworth’s H11 tool steel head studs are available for a limited number of applications.

Torque Specs & Other Factors

The ideal preload of a bolt will be provided by the torque specs supplied by the manufacturer. Torque values are always created under the assumption that the installation places 80% of the load while the other 20% is used by the “working load”. To properly tighten a bolt, a certain amount of preload is necessary. Although, physically tightening the bolt only accounts for some of the preload to reach optimum clamping force. The other factor that affects preloading the bolt is lubrication. Lubricating the threads of a bolt affects the amount of torque that is actually translated into preload. The type of lubrication also affects the amount of preload transferred as well.

Engine oil is a commonly used assembly lubricant that is not very effective. A proper assembly lubricant is a compound that contains two atoms of sulfur combined with molybdenum, also known as “Moly Lube”. When using ARP products, ARP recommends using its Ultra-Torque Assembly Lubricant.

Rod bolts experience the most stress. Many rod manufacturers include upgraded rod bolt options for this reason.

Rod bolts experience the most stress. Many rod manufacturers include upgraded rod bolt options for this reason.

Which Bolts to Upgrade?

Without a doubt, the most stressed fasteners in an engine are the rod bolts. Upgrading the factory rod bolt to an aftermarket offering can help to obtain higher performance levels from your engine if stock connecting rods are to be used. All aftermarket connecting rods include high-performance fasteners. Along with upgraded rod bolts, the rest of the rotating assembly’s fasteners (main bolts/studs) should be upgraded as well.

The addition of head bolts/studs offers superior cylinder head to engine block sealing. Along with increased clamping power on the cylinder head, head studs allow easy alignment of the head gasket and cylinder head during installation. However, due to space limitations in the engine bay, there are times that head studs cannot be used. Some manufacturers have incorporated an internal hex broach in the head studs to allow removal before removing the cylinder head.

Studs versus Bolts

Studs versus Bolts

Studs deliver a performance advantage over bolts as they provide more consistent and accurate torque loading. Unlike a bolt that is actually being “twisted” while it’s being torqued into place, a stud is only being stretched in its vertical axis. When properly installed, studs should only be finger-tight into the block. This “relaxed” mode ensures that the stud is only stretched and not twisted for accurate torque settings.

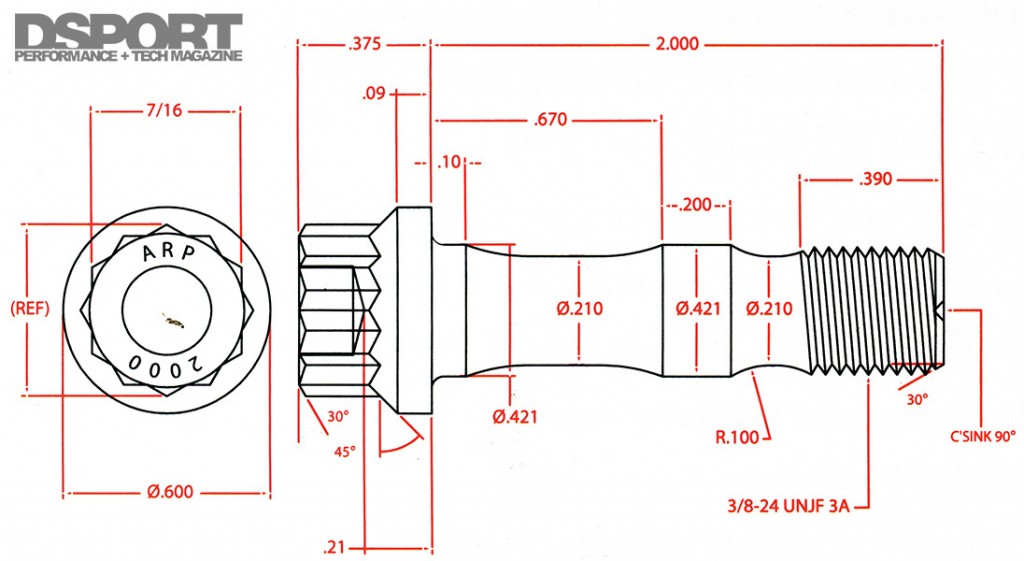

Exact dimensioning is needed to predict and control stretching.

Exact dimensioning is needed to predict and control stretching.