Every vehicle on the road has gauges. From entry-level compact cars to ultra high performance vehicles, monitoring the most basic to the most complex engine and chassis vitals is essential. Typical gauges cover basic information such as fuel level, coolant temperature range, and engine and vehicle speed. High-performance vehicles go a step further to include additional gauges that can inform the driver of more specific and critical engine activities.

But what if specific occurrences throughout a car, from the amount and speed of suspension compression to a drop in oil pressure at a specific turn, could be recorded and reviewed by tuners, drivers, engine builders and chassis engineers? Taking engine performance and vehicle dynamics to another level, modern datalogging hardware, sensors and software empower users with valuable information that can be used to extract the most that a vehicle has to offer.

Text by Arnold Eugenio

DSPORT Issue #105

Gauges vs. Dataloggers

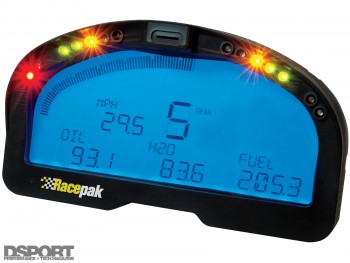

A basic engine monitoring system should include gauges that offer at a glance information within view of the driver that extend above and beyond what’s available from the OE gauges or gauge cluster. The aftermarket has offerings for gauges that record a number of different engine parameters with useful features like peak-hold recall or real-time playback. Additionally, aftermarket gauges are often coupled with their own, higher-quality sensors than those found on OE sets. The wider input-output voltage range allows the aftermarket sensors to monitor and display changes with greater precision and in smaller gradations.

A basic engine monitoring system should include gauges that offer at a glance information within view of the driver that extend above and beyond what’s available from the OE gauges or gauge cluster. The aftermarket has offerings for gauges that record a number of different engine parameters with useful features like peak-hold recall or real-time playback. Additionally, aftermarket gauges are often coupled with their own, higher-quality sensors than those found on OE sets. The wider input-output voltage range allows the aftermarket sensors to monitor and display changes with greater precision and in smaller gradations.

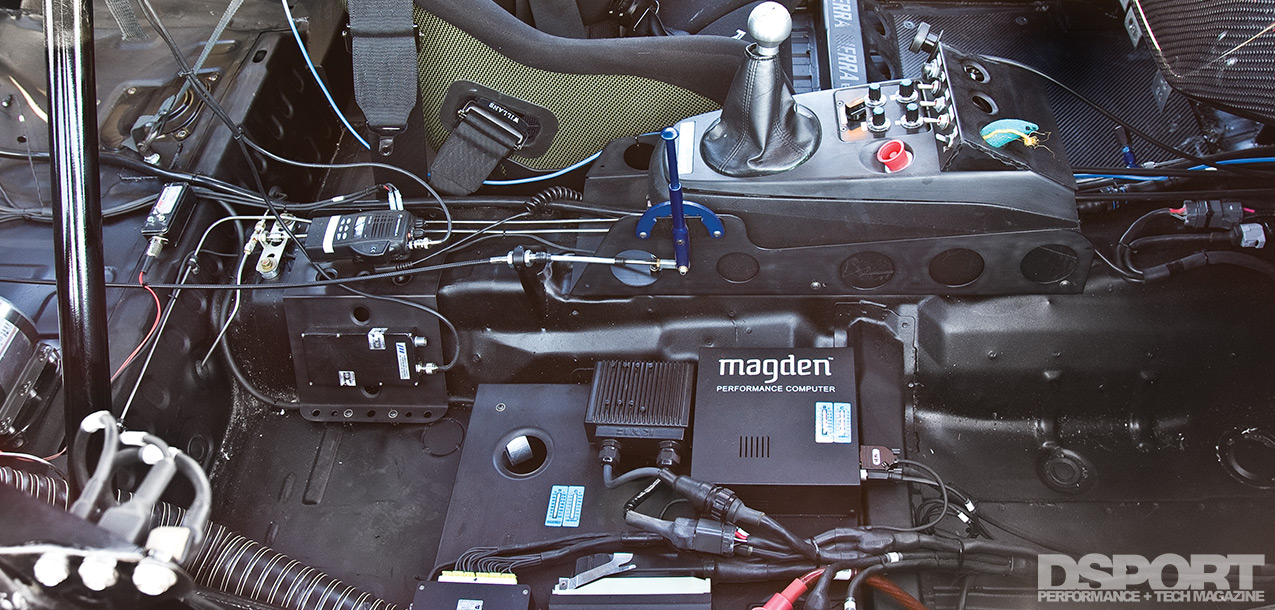

Beyond the individual aftermarket gauges available, there are a number of data acquisition systems (DAS) that provide more in-depth information. A DAS collects data from any number of inputs and sensors that it has and can record this information over time. This data can then be downloaded and fed into the provided datalog analysis software to more completely analyze all of the engine’s conditions at any given moment or even over a period of time. DAS units can also collect GPS-data and plot this information across a time and spatial range, allowing the driver and tuner to “see” exactly what the engine is doing at a given turn in a virtual representation of the track.

Even with a number of record/playback gauges available, a DAS has the advantage of being able to record multiple engine events (sensors) across a longer period of time, without distracting the driver from his primary focus driving. For the ultimate in driver and engine data monitoring and acquisition, a combination of appropriate gauges with warning lights and a DAS is ideal.

Stepping motor gauges rely on a control unit to process sensor signals into a sweep of the needle.

Stepping motor gauges rely on a control unit to process sensor signals into a sweep of the needle.

Wideband UEGO gauges like this AEM unit are self contained and convey quick and accurate air/fuel data to the display.

Wideband UEGO gauges like this AEM unit are self contained and convey quick and accurate air/fuel data to the display.

The future: The latest Multi- channel wideband UEGO controllers tap into each individual runner pre-turbo and allow monitoring and tuning of individual cylinders.

The future: The latest Multi- channel wideband UEGO controllers tap into each individual runner pre-turbo and allow monitoring and tuning of individual cylinders.

What’s So Important?

In terms of the type of information that should be monitored and recorded, of paramount importance is the engine’s speed (tachometer.) Aside from time and/or vehicle speed, this is the reference measurement from which other sensor information is plotted against. Additionally, having an engine spin beyond it’s preferred operating range is a surefire way to cause component or complete engine failure. Oil is your engine’s blood, so ensuring adequate oil pressure is also of the utmost importance. An accurate and precise air/fuel ratio meter is important in determining a properly-tuned state when the engine is under any type of load, while excessively high engine coolant temps and exhaust gas temps can also indicate an excessive lean condition or possible component failure elsewhere in the system. In today’s fuel-injected, multi-sensor engine configurations, monitoring your charging system or battery’s voltage output is crucial for sensors and engine’s electrical components to work within the appropriate voltage range. Where datalogging is concerned, individual wheel speeds can provide insight into traction and suspension-related concerns.