DSPORT Issue #268

By Michael Ferrara // Photos by Joe Singleton

Towing, heavy loads, high compression ratios, and sustained high boost levels are just a few of the realities that pose a challenge for engine oil on a turbocharged diesel engine. However, when regular oil change intervals are maintained with the proper engine oil, diesel engines will generally deliver two to five times the life of a gasoline engine. The majority of heavy-duty diesel engines use a 15W-40 viscosity engine oil. In addition to selecting the right viscosity, it’s imperative to make sure the engine oil you select also meets the manufacturer’s requirements.

In the case of our 2005 Dodge Ram 3500 with the 5.9-liter Cummins inline six-cylinder engine, oils meeting the Cummins CES 20086 specification are required. We decided to test two oils that both meet that specification on the dyno. While these two oils both meet the requirements of that specification, they are both very different in terms of composition, technology and cost. Will these differences show up on the dyno? Let’s stop the guessing and start the testing.

Chevron Delo® 400 XLE SAE 15W-40 Synthetic Blend Motor Oil

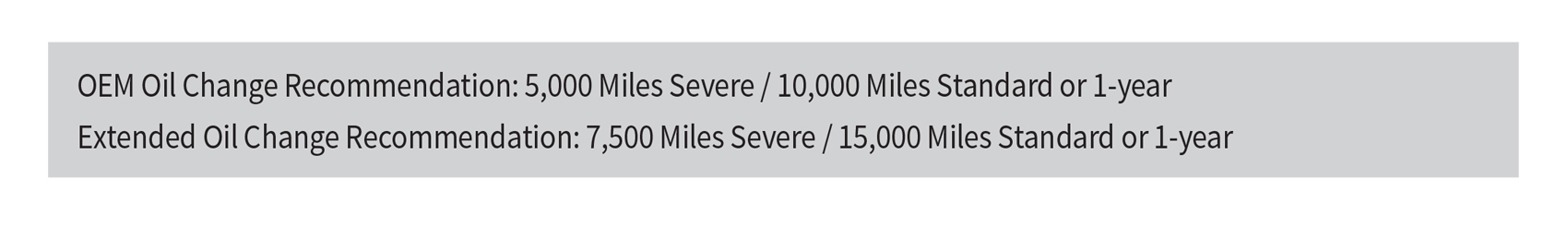

An extremely popular and highly praised engine oil option for both diesel and gasoline engines requiring an SAE 15W-40 engine oil, the Delo 400 XLE SB oil offers extended oil life (up to 1.5x OEM recommended interval*), high viscosity index, low deposit formation and excellent detergent package for exceptional cleaning. This oil meets the CK-4/SN API classification. This oil is readily available and can be found at the $15-$20 per gallon range at discount stores or in the $20-$25 per gallon range at the popular auto parts chains. Our application required 3 gallons (12 quarts), which we paid $71.79 (including tax) at AutoZone.

The base oils used in the formulation of Delo 400 XLE SB are a blend on conventional stocks with synthetic base stocks. This blend and the special additive package delivers exceptional oxidation resistance (flash point 446 degrees Fahrenheit) which reduces piston deposits and helps extend turbocharger life by eliminating coking of the oil in the center section. This oil also has a high viscosity index of 141 to provide consistent viscosity and oil pressure across a range of operating temperatures.

Since TriboDyn TRI-EX2 is the company’s most premium offering, it makes sense that a fully synthetic base would be part of its formulation. Second, TriboDyn TRI-EX2 is a premium oil that comes at a premium price, and it’s not yet in any mass-market retailers. We spent $209 (including tax and shipping) for three one-gallon containers through TriboDyn.com. This was nearly triple the price (2.9x), with a cost that was initially $137.21 dollars more. We say initially because we will factor in the projected fuel savings in our bottom line later. Third, the additive package in the TriboDyn TRI-EX2 oil features a patented ceramic lubricant.

According to TriboDyn, “the patented ceramic lubricant is attracted to areas of heat & friction. As pressures increase with RPM or load, the special TRI-EX2TM lubricants combined with the active “Ceramic Coating Technology” in the oil, forms a self- lubricating “Ceramic Film” in high load & heat areas, providing critical protection that actively seeks out areas needing increased lubrication, and at times not simply reduce or eliminate wear, but the ceramic film that forms, can also repair & fill in damaged surfaces.”

It’s this technology that we wanted to test. Lubricating ceramics like Molybdenum Disulfide (aka “Moly”) have been used for many years in engine oils as an exceptional additive for engine protection and friction reduction. If the patented formula in TriboDyn’s TRI-EX2 performed as stated, it would essential embed a low-friction, high-load bearing ceramic material on the metal itself. This would provide benefits in terms of friction reduction, protection and even corrosion resistance (especially important on engines running alcohol-based fuels like E85).

According to TriboDyn, the end result accomplishes the following: 1) Forms a low-friction ceramic coating in high load areas, 2) Enhances engine performance by reducing friction to deliver more power to the wheels, 3) Reduces operating temperatures, 4) Extends equipment life, 5) Improves fuel mileage, 6) Reduces oil consumption. 7) Reduces corrosion and 8) Reduces maintenance and repair costs.

The Vehicle

Our test vehicle is our 2005 Dodge Ram 3500 equipped with the 5.9-liter Cummins inline-six-cylinder engine. The factory power and torque ratings are 325 horsepower at 2,900 RPM and 610 lb-ft of torque at 1,600 RPM, respectively. Currently, we have just over 208,500 miles on the engine, which is bulletproof (wish we could say the same for the automatic transmission, as we are now on our fourth). The only mods in place are an AEM Cold Air Intake system and a MBRP 4” stainless steel exhaust system. The factory catalytic converter is still in place and it is running the OEM ECU with the factory flash. This truck has the 48RE transmission, which is a 3-speed, plus overdrive (4 forward gears in total) with a 4.10-ratio LSD rear-end as part of the tow package. It is running factory size LT265/70R17 tires.

The Test

While we are not able to test all the possible benefits of the TriboDyn TRI-EX2 technology in a day, we can put a few of the claims to the ultimate test on the dyno. If the dyno shows an increase in power with a switch from the Delo 400 oil to the TRI-EX2, we would be proving that a friction reduction has taken place. If we prove that we have decreased the amount of friction, we can also stipulate that operating temperatures will be reduced and that fuel mileage will increase (proportional to the power increase percentage). Unfortunately, only longer-term testing would be able to able to prove the other claims.

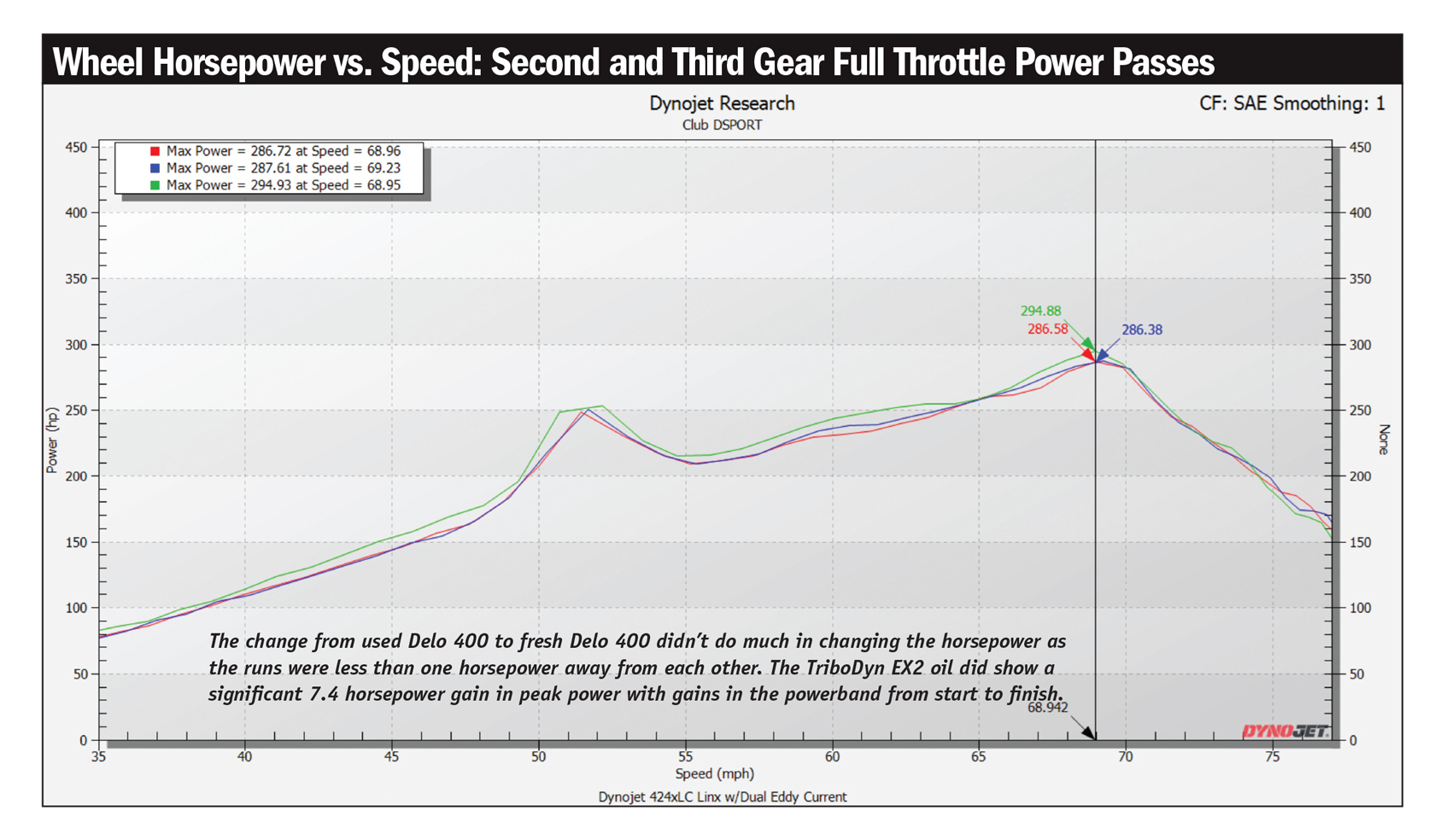

Our test would start with testing our vehicle that has about 6,000 miles since its last oil change on the Chevron Delo 400 oil. Aft er this test, a filter and oil change with new Chevron Delo 400 would be completed. Finally, another filter and oil change to the TRI-EX2 would complete our testing. All testing would be done with the coolant temperature between 80-81 degrees Celsius and the intake air temperature between 35-37 degrees Celsius. The engine would run for one hour before each oil change to ensure that the engine oil temperature stabilizes before the testing. A total of five runs would be made for each oil test (old Delo, new Delo, new TRI-EX2). The run with the highest peak horsepower for each oil would be graphed and compared.

Dyno Results

Despite what some of the content on the internet will tell you, we didn’t see a very appreciable diff erence in power output between the used and new Delo 400 oil in the dyno testing. The used oil managed a peak output of 286.72 horsepower while the new Delo 400 oil checked in at 287.61, not even a full horsepower more. With the TriboDyn TRI-EX2 oil in the engine, we did see a very significant increase in power. Peak power climbed to 294.93 horsepower, a gain of 7.32 horsepower from a simple oil change. It was nice to see that the power gain was everywhere across the power curve.

How did we gain a power increase with just a change to the TriboDyn TRI-EX2 oil? The TRI-EX2 oil reduced the power being lost to friction. The horsepower used to overcome the rings dragging on the cylinder walls and the friction on the camshaft and its lift ers was lowered as the TriboDyn TRI-EX2’s technology provided less drag on the contact points.

Fuel Mileage Improvement

While we will be keeping some logs to see the actual fuel mileage improvement with the TriboDyn TRI-EX2 oil, we expect to see the improvement mirror the improvement in increased power output. In looking at the results, the TriboDyn TRI-EX2 delivered a 2.55 percent improvement in power. Currently, our truck gets an average of 14.0 MPG. We now expect to see an improvement to 14.4 MPG.

Over the course of 15,000 miles, we would have burned about 1,071.4 gallons of diesel running on the Delo 400. On the TriboDyn TRI-EX2, we will burn 1,041.7 gallons, or 29.7 gallons less. With the average price of $4.86 per gallon for diesel in California, that equates to a savings of $144.34. While there was a higher initial cost for the TriboDyn TRI-EX2 oil, the fuel savings results in an actual savings of $7.13. Granted, this is based on the horsepower increase percentage matching the fuel mileage improvement. We will be keeping track to see if the actual results fall in line with our stipulation.

Treats the Metal, Not the Oil

According to TriboDyn, the TRI-EX2’s patented technology embeds into the metal. Hence, we plan to put this to the test at our next oil change. We will first test with the used TRI-EX2 oil and then put in the Delo 400 again. If the metal is actually treated, there should be a minimal diff erence in power output. We will then change the oil again (back to TRI-EX2) to see if any diff erences are realized. While our metal will be treated, the low-friction ceramic layer will eventually wear away if we don’t continue to use TRI-EX2.

The Bottom Line

We added more power and we are getting paid (through fuel savings) to make it happen. That’s a pretty good outcome. While the 5.9-liter Cummins engine has a good amount of contact surfaces as a six-cylinder engine with 102mm bores and 120mm of stroke, it only has a 3,200-RPM redline. As engine speeds increase, friction also increases. So, a smaller 2.6-liter inline six-cylinder engine with an 8,000-RPM redline may have as much or more horsepower lost to friction. Other factors such as rod ratio, type of valve train, piston ring thickness and a host of other considerations can impact the end results of reducing the friction within the engine.