DSPORT Issue #249

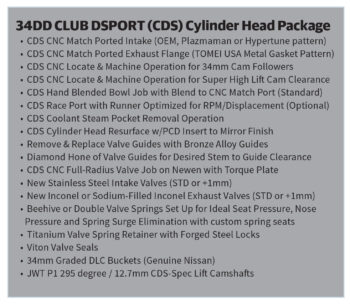

Text and Photos By Michael Ferrara

Some people are gearheads, but my Dad would call me a camhead. Before learning about forced induction and focusing on import performance, my goal was on getting the maximum power out of my small block 350cid V8 in my 1969 Camaro. As a high-school student earning minimum wage working at McDonald’s, I didn’t have much money. Every summer I would go to my Dad’s house in South Florida to work as an electrician’s apprentice doing piece work. You had to hustle in the humid heat with the sun beating down to make a decent wage. Every dime I made was put into making my Camaro quicker and faster. After reading just about every high-performance magazine I could find, I figured out that the camshaft is the single most important performance part for determining the power output, RPM range and personality of the engine. A higher lift, longer duration camshaft was in my future.

After saving up, I had enough money to get an upgraded cam and lifter set from Herbert Cams and proceeded to do my first cam install in my high school auto shop. Things didn’t go well as the OEM camshaft didn’t want to come out without a fight and that fight resulted in displacing the cam bearing. When my engine had trouble making oil pressure after the cam install, I ended up spending some more time in auto shop to rebuild the engine. While it was an ordeal, I eventually ended up with the high-performance cam that delivered that right rumpety-rump idle and 450-plus horsepower I was hoping to get. This eventually put me on the search for the perfect cylinder head, camshaft and intake manifold combination. By the time I entered college, I had a 650 horsepower, 327cid V8 small block with a roller cam that turned 8,700RPM and never lost a race. Admittedly, I’ve always been a camhead. Even though conventional thinking downplayed the importance of cylinder head and camshaft performance in forced induction applications, I was in the minority that believed that the engine with the right camshaft and cylinder head work would perform considerably better than an OEM setup when forced induction was added to the mix. As it turned out, I was right.

Boost vs. Horsepower

Running high-boost pressure numbers is never a good idea when it’s not necessary. Let’s look at two 2.0-liter, four-cylinder engines running the same turbo setup and both making 1,000whp. If engine A runs 60psi to make 1,000whp and engine B only runs 45psi to make 1,000whp, which engine is better? If you answered A, you are being misled by your information sources. If you answered engine B, you are correct. A well-designed engine package will allow you to meet a desired power goal at a lower boost level. Remember, the boost pressure is the pressure of the air not getting into the engine. Higher than necessary boost pressures result in excessive compressor outlet temperatures, inefficient turbocharger operation and high intake air temperatures that make the engine more likely to encounter detonation. By making an engine more efficient at filling the cylinders, more power is realized at a given boost pressure.

Big-Power RB Engines

Since I’ve had the same turbochargers on my R33 GT-R for the past 20 years, I’ve spent a great deal of time making my RB engine work as efficiently as possible to extract maximum performance. Over 1,250 horsepower to the wheels from a 2.6-liter RB26 with the twin IHI RX6B turbo setup is a feat no other has accomplished. I’ve dyno tested and raced with low-, mid- and high-lift camshafts. I’ve tried standard and oversized valves and I’ve tried mild to wild porting of the cylinder heads. So what works? RB engines love high-lift camshafts and 90-percent of the RB engines built at Club DSPORT feature high-lift camshafts from 272 to 292 degrees of advertised duration. As for oversized valves and cylinder head porting, the two go hand in hand. OEM, mild and mid-size ports work best with standard size valves while oversize vales require a reshaped port optimized for the larger valve size. Ultimately, the ideal port size is predicated on the engine size and the engine speed operating range. The key is to not sacrifice port velocity with massive ports. While it will show better flow numbers on the bench, it won’t fill the cylinders with as much air as a higher-velocity port and you will lose power. Nissan did an exceptionally good job at establishing the proper port sizes for a 2.6-liter engine spinning to 8,000RPM. If you are going to keep the factory displacement and RPM limit, doing more than a bowl job, port match and polish of the ports will result in diminishing returns. If you are increasing the displacement, increasing the RPM limits and raising the powerband, there will be benefits to going to oversized valves and port optimized for those larger valves. Notice how I made no reference to the boost levels that will be encountered. Expected boost pressure shouldn’t factor into the decision on port size. If someone says you need big ports for high boost levels, smile and walk away.

The Concept

What if the Nissan RB26 cylinder head was engineered today instead of 40 years ago? What would be the same? How would it be different? Before answering that question, a look back to the original design goals for the RB26 cylinder head must be first considered. For the RB26DETT, high specific output and endurance type racing was expected. For street applications, the RB26DETT engine was to be fitted in halo-level flagships for Nissan so reliability and performance was a must. Given those parameters, an RB26 cylinder head designed today would still have some similar features. By today’s standards, the intake port, valve angle and combustion chamber design are still current. The RB26 cylinder head features symmetric intake ports which position six identically shaped intake ports on center with each of the six cylinders. This design helps equalize the cylinder filling and power output across the cylinders resulting in an engine that runs smoother and stronger. The included valve angle of 46-degrees is still on par with more modern 4-valve engines like the 4B11 (47 degrees). If packaging would allow for a taller intake port perhaps a narrower angle would be used today. As for the combustion chamber, the RB26 features a pent roof design with twin quench pads. For a port-fuel injection engine, the combustion chamber is still a relatively current design.

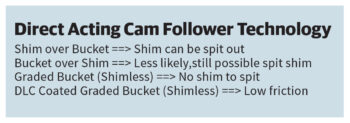

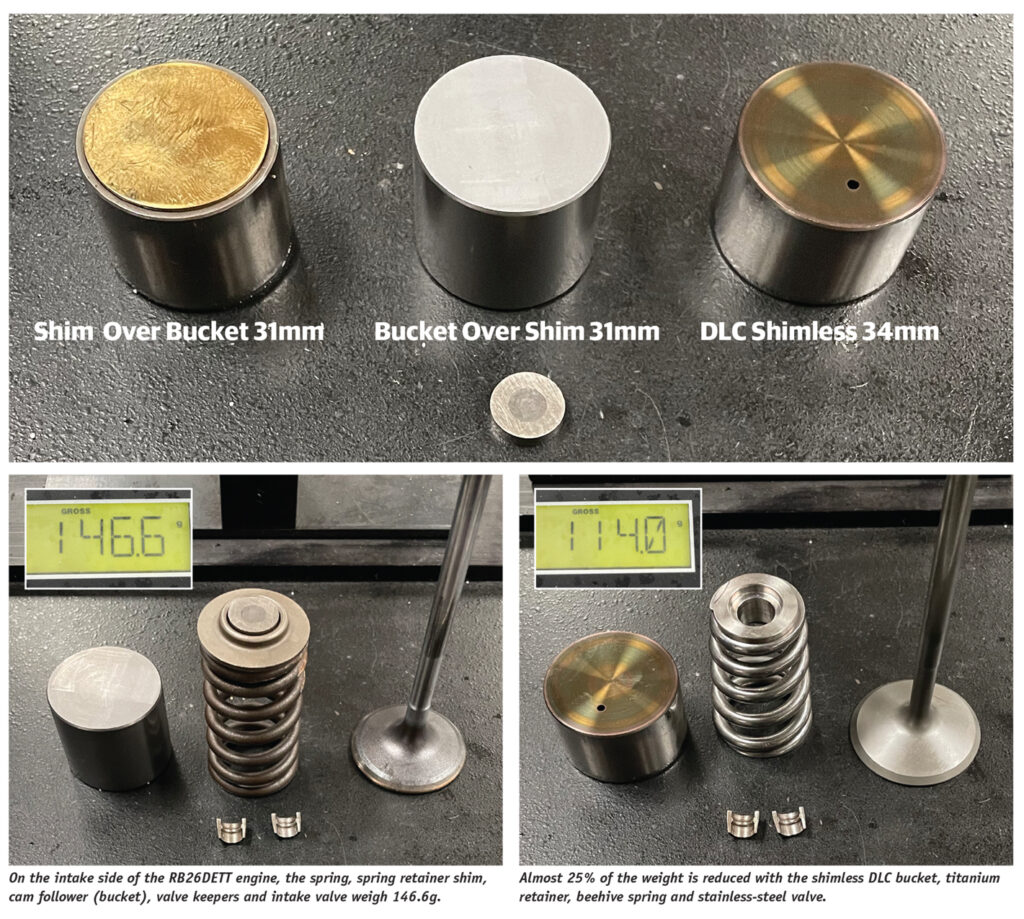

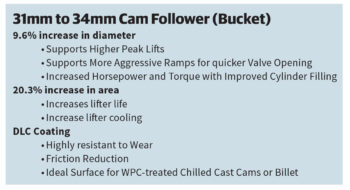

As for what would be changed if the RB26 cylinder head were designed today, let’s leave variable cam timing off the table for a second and focus on the rest of the cylinder head. While the shim under bucket design to set valve clearance performed better than the shim over bucket in performance applications, there is a better solution today with graded buckets (cam followers). By having a range of cam followers of different graded thicknesses, no shim is used. This eliminates the potential for a shim to get sideways or fall out when the valvetrain encounters valve float (valve spring surge) and other instabilities during two-step and rev limiter operations where these failures most often occur. For nearly 10 years, Club DSPORT has been upgrading RB26 cylinder heads to use a shimless graded bucket in the OEM diameter (31mm). In addition to using a graded bucket, an RB26 designed today would likely use a larger diameter bucket to take advantage of higher lifts and more aggressive cam profiles. Looking at the history of Nissan engines, you’ll find that the VG and nearly-all RB engines used a 31mm diameter cam follower while the later VQ and VR engines moved to a larger 34mm diameter bucket. Several high-performance OEM cylinder heads found today also feature CNC machining on the intake ports. Some are just light cleanup of the ports to gasket match while others are a fully CNC ported intake tract.

In terms of variable cam timing, HKS pioneered the VCAM system which adds variable intake cam timing. This system allows intake cam timing to be advanced at lower engine speeds to increase low-end torque and turbo response. As engine speeds increase, intake cam timing can be less advanced to optimize power at higher engine speeds. It’s a system that works very well on stock to moderately modified vehicles. While the system can deliver low- end and midrange punch, the peak lift available from the system is relatively conservative even with the ”Pro” camshaft. As a result, the system isn’t the best choice for maximum effort builds.

RB26 Cylinder Head Optimized

Performance gains are meaningless if reliability is sacrificed. When we considered trying to take RB26 cylinder head and camshaft performance to a new level, we wanted to rely as much as possible on proven solutions. Looking across the entire range of Nissan engines answered our most pressing questions. Could we use a 34mm bucket on an RB cylinder head? We found the answer on the RB25 NEO cylinder head which uses a 34mm bucket as delivered. While this bucket wouldn’t work for the high-lift range we planned for the RB26, it at least told us that the RB26 cylinder head might be able to use a 34mm bucket if properly machined. We found proper 34mm DLC coated bucket in the Nissan parts catalog the too.

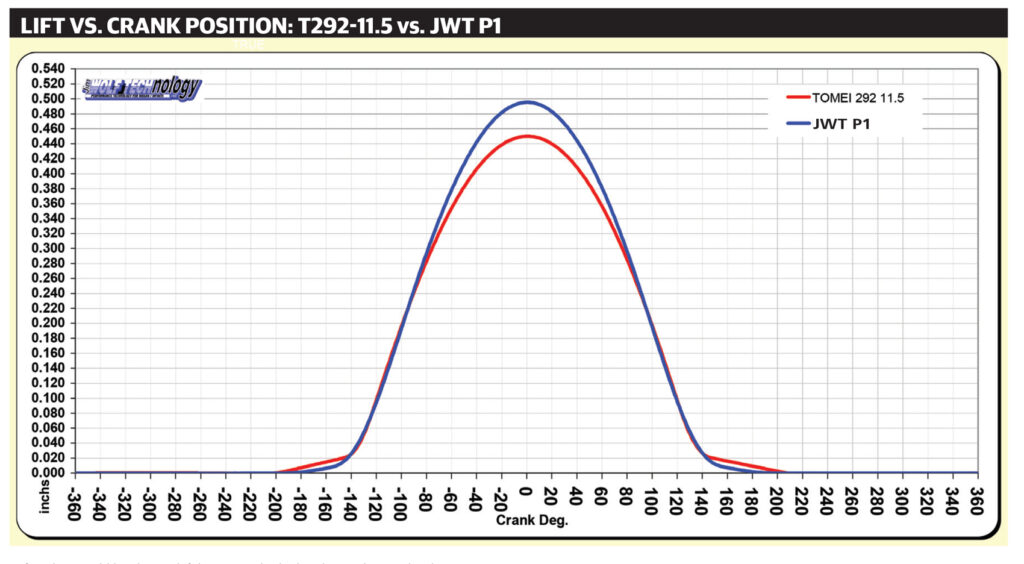

To further validate our concept, we turned to Jim Wolf Technology (JWT). JWT has an insane amount of experience racing KA24, VG30 and VQ engines for several years. They’ve modified VG30 heads to accept larger VQ buckets and run significantly more aggressive and higher-lift camshafts thanks to the larger diameter bucket. Clark Steppler of JWT was able to use a cam profile already proven on a 34mm bucket to make the prototype camshafts for testing. Since most of our higher-horsepower RB engine builds rely on 292 duration high-lift cams from TOMEI USA, we decided to use a cam profile with a similar amount of duration at 0.050” and 1mm lift. However, the peak net lift would be in the 12.6~12.7mm range instead of 11.4mm. When looking at the overlay of the two lift curves, it’s easy to see the advantage of the higher lift. The first-prototype or P1 profile from JWT shows how the time that the valve is open at 11mm and higher goes from 40-degrees with the TOMEI USA 292 to 80-degrees with the JWT P1 camshaft. For a full 180 degrees of crank rotation, the P1 profile is delivering higher lift than the benchmark TOMEI USA 292.

Projected Gains

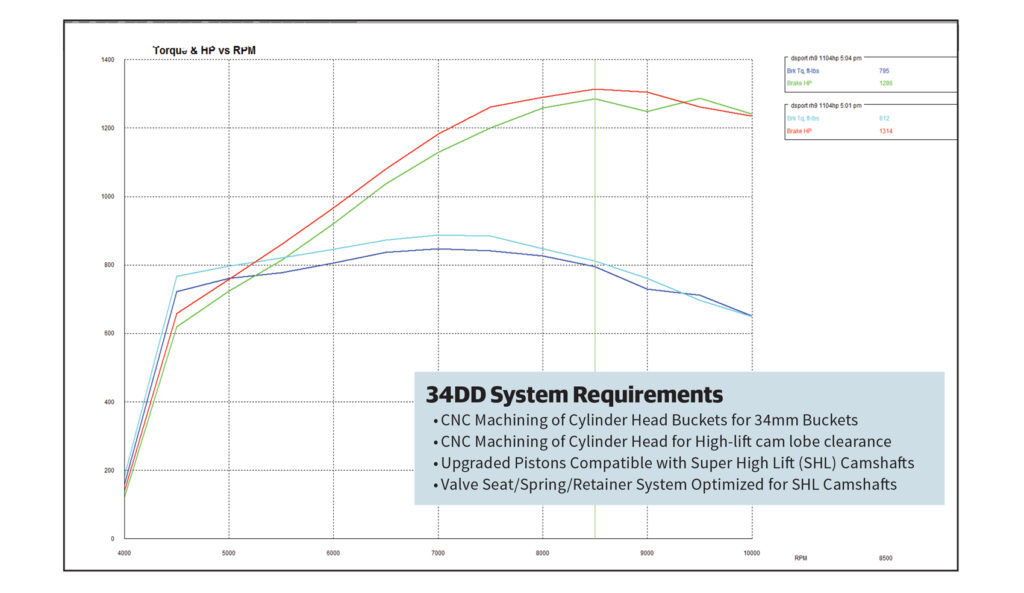

The amount of performance improvement is going to vary depending on the benchmark used for comparison. You may recall that we have dyno tested a currently-available high-lift RB26 cylinder head with 292-degree high-lift cams that delivered over 120 more horsepower to the wheels on a 500-600 horsepower RB engine. When we plug the numbers into the engine analyzer program and compare it to the 292-degree high-lift benchmark, we see some impressive gains and a shift in the power curve slightly to the right. The average torque gain is 47lb-ft while peak torque increases 32lb-ft but occurs 500RPM sooner in the simulation. Peak power also goes up 40 horsepower at peak while the average goes up 54 horsepower on a 1,200 horsepower turbo- restricted engine. With a larger turbo in place, gains would be in the neighborhood of 60-100 horsepower.

Heads Up

After finalizing the development and testing of the “34 Double D” package for the RB26, Club DSPORT plans to offer the package to racers. The package will consist of a complete cylinder head with all the valvetrain in place for a bolt-on solution. Port matching is done to match the customer’s OEM, Plazmaman or Hypertune intake manifolds. The package will require “approved” pistons which are available separately or as part of any Club DSPORT RB26 engine build. While pricing is still to be determined, the complete package should start just under $10,000 and go to $12,500 depending on the level of porting and chamber work. The package cost includes a new cylinder head, all necessary machine work and the camshaft and valvetrain components needed to complete the top-end package.