DSPORT Issue #242

By Michael Ferrara

For more than a decade, we’ve been preaching about the advantages of “lithium” batteries (technically lithium-iron-phosphate or LiFePO4 to be exact). We’ve tested many offerings from different manufacturers. Some LiFePO4 batteries tested have been on the budget side while others have been big-dollar, top-shelf offerings. We’ve tested these batteries on the bench in a lab setting and in real-life conditions on both street and race vehicles. After more than 10 years, we have learned a great amount and seen the good, bad and ugly of LiFePO4 batteries. When we heard about our friends at Buddy club bringing the MEGA-LiFe LiFePO4 battery lineup to the USA, we reached out to get some product for testing. Our initial results have been excellent, and the product’s performance, value and warranty deserve more than a mention. After explaining the ins and outs of LiFePO4 batteries, we will get into the specifics of the MEGA-LiFe batteries.

Bi-Polar Disorders

Just as lithium is prescribed to treat the mania associated with bipolar disorder, lithiumiron phosphate technology can be used to treat the bipolar disorders associated with your lead-acid battery in your vehicle. The results can be truly impressive in terms of increased cranking performance and extended battery life while tipping the scales at about one-third of the weight in most applications. Compared to lead-acid batteries, LiFePO4 batteries are also zero maintenance while featuring low self-discharge rates that are ideal for cars that aren’t driven daily. While LiFPO4 batteries have lived beyond the budgets of many enthusiasts for several years, lower cost offerings have hit the market in recent years. While the price of premium lead-acid batteries continues to rise, LiFePO4 batteries have been dropping in price over the past few years. Today, a number of LiFePO4 battery options can be found at just 2 to 4 times the price of premium lead-acid batteries instead of the 5 to 15 times pricing of 10 years ago. Considering that a quality-built LiFePO4 battery will have up to five times the lifespan of a premium lead-acid battery when treated properly, paying more up front may result in paying less in the long run. During that entire time, the benefits of the increased performance and reduced weight of a LiFePO4 battery can be realized.

Smart vs. Dumb Batteries

Conventional lead-acid batteries do not require a brain to function properly in an automotive environment. However, LiFePO4 batteries must incorporate a “brain” or Battery Management System (BMS) to function properly. While the quality of lead-acid batteries varies based on purity, plate designs and construction quality, the quality and performance of lithium-iron phosphate batteries is highly dependent upon the intelligence of the battery management system in addition to the design and construction quality. Since LiFePO4 batteries can discharge and charge at up to 10 times the rate of a lead-acid battery, controlling the current flow is a must. The BMS is also responsible for setting the individual cell voltages, cell-to-cell voltage balance and in many cases has a short-circuit and high-temperature cut circuit in place.

The performance of a LiFePO4 battery is tied to the design and performance of the BMS. A well-designed BMS will allow the battery to charge and discharge at optimal rates while maintaining ideal voltage from cell-to-cell. A BMS that lets the cells within the battery charge at too high a voltage for too long can oxidize the cathode material and cause carbon-dioxide to build up within the battery. In severe cases, the battery case can explode. A BMS that lets the cell voltage drop too low during discharge can breakdown the electrodes. Due to small variations in manufacturing, the individual cells of a battery will charge at different rates. In a lead-acid battery, the voltage of the cell that charges quickest reaches a limit while the slower charging cells take some extra time to get to the limit. Essentially, lead-acid batteries are self-equalizing. With LiFePO4 batteries, self-equalization doesn’t take place. Without proper BMS control, the quicker charging cells would continue to increase in voltage (perhaps beyond the limits) while the slower charging cells take more time to hit the target voltage. A properly-designed BMS charges each cell to full and safe levels.

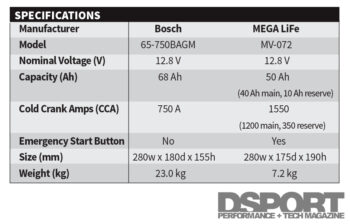

Specifics MEGA-LiFe LiFePO4

Like the majority of LiFePO4 batteries on the market, assembly of the MEGA-LiFe batteries takes place in China. However, the cells are made in the USA while the design of the battery was done by Buddy club Japan. Japanese design, USA parts and Chinese assembly is not something seen every day, but it seems to work well. As a result, MEGALiFe are able to offer one of the best warranties available for any LiFePO4 battery: a 36-month replacement warranty replaces any failed MEGA-LiFe battery.

All the MEGA-LiFe standard batteries also feature a secondary reserve battery pack for emergency starting. If a battery drain causes the main section of the battery to reach a low-voltage limit (lights are left or stereo plays too long without the car running), the battery’s BMS cuts off the connection to the main cells so that no damage occurs to the battery. Of course, the result appears to be a completely dead battery when someone attempts to start the vehicle after this event. Fortunately, the secondary reserve battery can be activated with a press of a button on the battery and the vehicle can be started to allow the charging system on the vehicle to charge all the cells back up to full status. It’s a valuable feature that acts like you always have a jumper pack on hand. This is also a feature that is ideal for vehicles that may not get started for months at a time. MEGALiFe racing batteries do not feature the secondary reserve cell in order to minimize weight.

MEGA-LiFe’s proprietary casing system exceeds the industry standard 10m drop test and 3m submersion testing (IPX8). These batteries can be mounted in any orientation.

Fitted Solutions

MEGA-LiFe batteries are made in a number of popular group sizes for direct fitment on many vehicles. If there is a matching group size available for your application, the easiest solution would be to order that specific replacement. For racing applications or for applications having a different energy storage and delivery requirements from OEM, the ideal replacement battery must meet the energy delivery, energy storage and space requirements of the application.

When the performance AGM batteries gave up in our DSPORT Tow Vehicle after 5-1/2 years of service, we decided that this would be a great application for the long-term testing. This application originally had a pair of group 65 batteries. Unfortunately, this wasn’t a group size that was available as a MEGA-LiFe direct fit. Based on the sizing, load and reserve requirements and what was available in stock, we ended up with a pair of MV-072s. While they had no problem securing in the factory location with the OEM hold down, the MV-072 had the terminals reversed compared to the group 65. This required some additional installation time to reroute the battery cables to reach, but it was well worth the time. Now, the Dodge Ram 3500 with the 5.9-liter Cummins starts like a champ while we’ve removed nearly 70 pounds off the front of the vehicle. We also plan on fitting a smaller MEGA-LiFe battery on our Project RH7 GT-R.

Battery and Charging System

The basic system can be visualized as a pool (the battery) with multiple drains (the devices that require the electrical power) and a single fill (the alternator). Physically larger batteries will tend to have bigger pools of energy storage (measured in amp hours or Ah). Unfortunately, larger batteries weigh more which is not desirable for performance applications. The size and number of drains on the battery will determine how quickly the stored energy in the battery can be used. Bumping that 1,500 watt sound system for 30 minutes with the engine off or leaving the lights on for a few hours can result in draining so much energy from the battery that not enough remains to start the engine. For a performance application, choosing high-efficiency components with low energy requirements (i.e. brushless fuel pumps and engine cooling fans) reduce the energy storage requirements (battery size) for a given application. As for the alternator, it’s important to have an alternator that can produce enough energy to power all the components under maximum load and still have something left to fill the pool. Hence, you wouldn’t want to use a 70A alternator on an application that produces up to 110A of electrical load. each individual cylinder.

Supply and Demand

Why do some vehicles’ electrical systems run flawless while others are problematic? Many times, it boils down to the systems design and the overall supply versus demand factor. Even some OEM electrical systems are “borderline” in terms of the available supply and the realistic demand on the system. Let’s take a look at the factors that influence this supply and demand.

Here are the supply side economics. When a 36-pound lead-acid OEM battery is replaced with a 6-pound lead-acid racing battery, the storage capacity of the system drops by over 80 percent (the drop in storage capacity is roughly proportional to drop in weight when like technology batteries are used). That means if you could leave your lights on for 30 minutes with the OEM battery and still have just enough energy left to start the engine, leaving those same lights on for more than 5 minutes with the small battery would leave your vehicle in need of a jump or tow. Still, this may be okay for a street application where the electrical system is never run without the engine running and the engine starts on the first attempt all the time (not like an E85 engine trying to start in 40-degree weather). For those looking to have their cake and eat it too, upgrading to a lithium-ion battery (more expensive cake) can usually provide a battery with 100-percent of the storage capacity at just 25-to-35 percent of the weight. Hence, a 9-pound lithiumion battery could have the same storage capacity as a 36-pound lead-acid battery.

Higher flow fuel pumps, additional fuel pumps, higher flow cooling fans, ignition amplifiers and high-power car audio systems increase the demands on the electrical system. Going from an OEM fuel pump to a triple fuel pump setup could easily increase the load demands by 40~50A. An aftermarket high-performance fan may pull an additional 10A, while a bass-booming sound system can pull over 80A for those 1000 watts of boom. Nearly every component added for performance or pleasure increases the size or number of drains on that storage pool. Hence, having an alternator capable of keeping up with the peak electrical current demands on the system is key. Otherwise, the system will be fighting a losing battle: unable to fill the pool as fast as it can be drained. With many of the import applications, the OEM equipped the vehicle with a different output alternator based on the options on the vehicle. Some aftermarket high-output alternators may also be available for some applications. As long as your alternator has at least 10A of headroom above and beyond the peak electrical demands that your system will experience (i.e. 100A alternator on a system when 90A is peak current demand), you should not run into any issues. Of course, one should also consider the options to reduce demand. LED lights in place of conventional will reduce current draw as will brushless fuel pumps and brushless cooling fans. In addition to being more efficient at peak output, brushless fans and pumps can also be speed controlled to reduce the output under low-load situations. For example, a brushless fuel pump may only pull 3A of current at idle when reduced to a low speed, while a brushed fuel pump may pull 15A in the same application. Under full load, the brushed pump might pull 30A of current while the brushless pump at full speed may only pull 15A.

Performance Battery Specs

Once you’ve narrowed down battery selection to what can physically fit, there are two performance specs provided for automotive batteries that should be understood before any battery upgrade is considered. A battery’s current delivery (measured as Cold Cranking Amps or CCA) and a battery’s energy capacity (expressed as amp hours or Ah). Both must be considered when selecting a replacement battery.

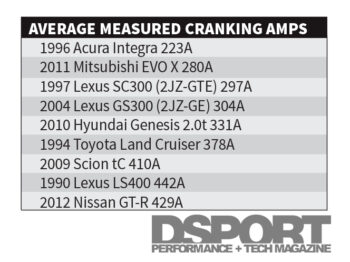

Cold Cranking Amps

You have probably heard numbers being tossed around with respect to a certain battery having 550 cold cranking amps (CCA) or another battery having 750 CCA. Nearly all automotive batteries will have a CCA rating printed on them. Batteries with higher CCA ratings can deliver more energy per second to meet the demands of engines requiring more energy to start. When an engine is cranking, the peak current draw is occurring on the battery. The longer it takes to crank, the tougher the strain on the battery. There are several factors that increase the minimum required CCA to start an engine. In general, the following will increase the minimum CCA needed to start an engine: increased displacement, increased number of cylinders, increased compression ratios, lower oil temperatures. Over time, a battery’s ability to deliver energy under a significant load can decrease. Simply getting a battery to charge up to 13.5 volts without a load applied doesn’t mean it will get the job done. Only by load testing a battery can one determine if the battery is still functioning properly. When selecting a replacement battery, always choose a replacement with a higher (preferred) or equal CCA rating.

A battery’s CCA rating is a function of its physical size, chemistry and construction. In the same family of batteries, a physically larger battery will generally, but not always, have a higher CCA rating. The CCA rating is usually more related to the construction and chemistry of the battery. Premium lead-acid batteries in a comparatively smaller size can have a larger CCA than a larger non-premium lead-acid battery. A lithium-iron battery in an even smaller size can have a higher CCA rating than a physically larger premium lead-acid battery. So physical size, construction and chemistry all factor into the a battery’s CCA or current delivery rating. For a pure racing application, selecting the lightest battery that meets the minimum CCA rating that the engine requires will get the job done. For all other applications, the battery’s energy capacity must also be considered.

Amp Hours Ah

If you have a friend that purchased a racing battery for his/her streetcar only to end up with a car that often needed a jump start, you’ve met someone that never considered the energy capacity of the battery. While the capacity of a fuel tank or fuel cell is expressed in gallons, the capacity of a battery is expressed in amp hours or Ah. A battery might have a 10Ah rating or a rating of 130Ah. What does the Ah rating mean? A 30Ah battery has enough calculated capacity to power a 30amp load for one hour, a 15 amp load for two hours, a 3 amp load for 10 hours our a 1 amp load for 30 hours. As long as the load in amps and the time in hours multiplies out to 30, a 30Ah battery would have the capacity to meet the demand.

Unlike the CCA rating of a battery, the Ah rating of a battery may not be identified on the battery. In that case, an internet search for the group size of the battery can usually provide a very close estimate. In general, the Ah or energy capacity rating of a battery will be a function of its physical size and chemistry. For the same chemistry of battery, a battery twice the physical size and weight will have twice the energy capacity. Just like a fuel cell, a five-gallon fuel cell is going to have twice the volume as a 2.5-gallon fuel cell. A lead-acid 50Ah battery will be half the physical size of a lead-acid 100Ah battery. When a battery chemistry is used that has a higher energy density, both the weight and volume of the battery can be reduced. Lithium Iron Phosphate (LiFePO4) is the chemistry used in automotive “lithium” batteries. This technology has about three times the energy density of lead-acid batteries. As a result, the physical size and weight of a “lithium” battery may be 1/3 or less of a lead-acid for the same amount of energy capacity.

Battery Maintenance

A battery will live a long and happy life when it is discharged and charged properly. As for being discharged properly, a battery must have sufficient capacity for its application as to not go below 50 percent of its stored energy level. When it is stressed to go below this level, the battery will begin to lose its storage capacity over time. Lead-acid batteries will experience sulfation (the buildup of lead sulfate crystals on the plates) making them less efficient.

The improper charging of a battery will have the most adverse effects on battery performance and life. Dumb and cheap battery chargers may appear to save a few bucks in the short run while actually costing the owner hundreds or thousands of dollars in the long run by severely shortening the life of the batteries it charges. While infrequent and inadequate recharging can lead to sulfation on lead-acid batteries, “overcharging” has even more detrimental effects. Overcharging can cause the water in the electrolyte solution to evaporate and may also expose the plates to air where they will quickly oxidize (reducing the reserve capacity of the battery).

For lithium iron phosphate or LiFeSO4 batteries only smart chargers recommended by the battery manufacturer should be used. We’ve seen first hand the damage that can be done to a LiFeSO4 battery when charged on a non-approved charger (even a smart one).

The Bottom Line

When the engine is not running, the alternator is not producing any electrical energy. As a result, the only supply of electrical energy is at the battery. The primary function of the battery is to have enough energy on hand to power the starter. Once the energy in the battery is used to start the vehicle, the amount used will be replenished by a properly operating charging system on the vehicle. On certain applications where energy is needed when the engine is off, a larger-capacity battery may be desirable. If you are in the market for a battery upgrade, be sure to take a look at what the MEGA-LiFe battery lineup designed by Buddy club has to offer.

Maintenance Schedule

Maintenance Schedule:

Inspect your battery’s electrolyte levels. If the battery has removable vent caps that allow filling, fill with distilled water

to recommended level if low. Gel, AGM or maintenance-free batteries do not allow fluid level adjustments, so this step cannot be done.

Clean your battery terminals and ensure that both ends of the main cables are tight. Use corrosion-preventing grease on terminals. If the cables have frayed conductors or fit loosely, replace.

Check the battery voltage with the vehicle off and with the vehicle running to confirm proper standing and charging voltages of the battery and charging system. A standing battery should show between 12.4 and 13.2 volts. With the engine running for at least one minute, the battery voltage at idle should read higher (between 13.2 and 14.2 volts). This indicates that the charging system is charging the battery.

Inspect physical condition of battery. If the case is distorted, cracked, leaking or if the battery builds excessive heat when the vehicle is running, replace the battery immediately.

Inspect the alternator belt and ensure that it is not slipping. If black rubber dust or other signs of slipping are present, replace and re-tension the belt.