The perfect clutch. Is it a dream, or is it a reality? The reality is that there is no one clutch that is the perfect clutch for every application and every driving style. As a result, even clutch manufacturers will generally have multiple offerings for a particular vehicle based on the intended application. HKS decided to engineer some clutch solutions that may be the perfect clutch for the majority of those out there with mild-to-wildly modified street vehicles. The HKS LA or Light Action series of clutch is designed to handle the power levels of engines up to 600ft-lb of torque (380ft-lb for single disc) while providing light pedal effort, quiet operation, excellent clutch modulation and superior engagement. The HKS LA clutch series is available in both a single and twin configuration for many of the most popular Japanese performance platforms. Recently, we had the opportunity to dissect one of these clutches and put it to the test on a Nissan R34 GT-R that recently received a Club DSPORT RB28 engine capable of 1,000whp operation.

Multiple Multi-Plates

We’ve had the experience to drive a number of RB26-powered vehicles with a number of multi-plate clutches from just about every Japanese clutch manufacturer including Exedy, OS Giken, ORC and ATS. These have been twin- and triple-clutch configurations. We have also had the experience of driving our own Project RH8 R33 GT-R with a Club DSPORT- engineered quad carbon-carbon clutch built by Tilton. We’ve loved some of these clutches and hated others along the way. In nearly all these setups, pull clutches were converted to push by means of a mechanism or the employment of a clutch release bearing. In nearly all cases, the vehicle would be harder to drive as the amount of travel in the pedal between full engagement and full disengagement of the clutch would be cut to one-half or one-quarter of its normal travel range. With the pedal also requiring up to twice the original effort to move, these were not clutches for the untrained leg.

HKS Light Action

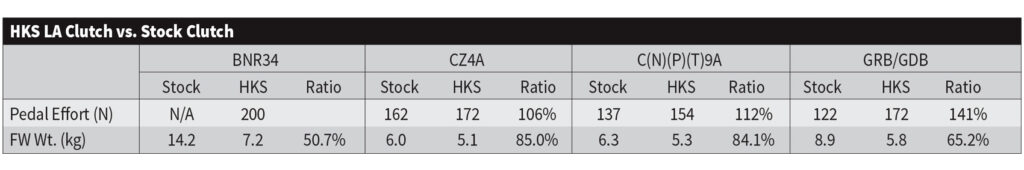

One of the primary design goals with the HKS LA series of clutches was to make it very easy to drive. Making it easy to drive meant low-pedal effort, easy engagement and low noise. In many of the applications, HKS was able to keep the pedal effort for its twin-disc clutch just slightly above the OEM clutch with an increase on the order of 10 to 20% more effort, which was hardly noticeable. To make the engagement as easy as possible, HKS chose to use full-face, premium semi-metallic, woven organic friction material on the spring hub discs. These steel-backed linings feature a marcel wave spring between the backings to deliver a much smoother engagement. Where cheap molded organic facings will fail at higher engine speeds when temps reach 500 degrees, the premium materials used in the HKS woven, semi-metallic clutch discs can work at temps up to 700 degrees at engine speeds more than double the failure point of the cheap organics.

Kill the Noise

The HKS LA clutch series also uses a heavy-duty sprung hub, which helps to quiet down the transmission noise that occurs when a solid hub is employed. Noise from the plates is also minimized thanks to “lifting plates” on the center-steel floater that keep plate noise to a minimum when the clutch pedal is pushed. For every HKS LA application, the flywheel has been lightened from 20 to 50 percent. This lightened flywheel is manufactured from chromoly steel and features an integral ring gear that has been machined directly on the flywheel. This allows the flywheel an additional degree of safety, as there is no way this starter ring gear can separate from the flywheel. At high engine speeds, starter gear rings that are pressed, pinned or welded into place can separate and become a serious safety hazard that can cut through the OEM bellhousing upon separation.

Pulling for You

The HKS LA clutch for the Nissan R34 GT-R also maintains a pull design like the original clutch. Pull clutches allow for a design with reduced pedal effort and improved ratios, hence, that’s why most modern vehicles come with a pull-type clutch. In driving with the HKS LA clutch in the R34 GT-R, it was hard to distinguish it from the OEM clutch in terms of pedal effort or clutch modulation and engagement. The lighter flywheel and lighter clutch cover allowed the engine to free rev slightly quicker.

More Torque Capacity Please

When an engine is fitted with upgrades and a calibration to safely increase its torque output, it can easily result in overpowering the factory clutch. Once overpowered, the factory clutch disc can glaze, resulting in even lower torque capacity. When this occurs, a new clutch with higher-torque capacity is a must to establish a long-term solution.

Increased Torque/Power Handling

There are four ways to increase the power handling of a clutch system: 1) increase the diameter of the clutch discs; 2) increase the clamping force of the pressure plate; 3) increase the coefficient of friction from the friction material; or 4) increase the number of friction surfaces. Increasing the diameter of the clutch system usually isn’t an option on modern vehicles, as the OEM has already fitted in the largest diameter clutch possible in most cases. In fact, moving from a single- to a multi-plate clutch often facilitates the change to a smaller diameter clutch. In the case of the HKS LA twin-disc clutches, the clutch diameter is 215mm (8.5 inches). However, the doubling of the number of friction surfaces doubles the torque capacity of a clutch, with all other factors being equal. So, there is plenty of opportunity to reach the desired torque capacity in most cases.

The lifting plates attached to the center plate keep the assembly quiet as can be for a twin disc clutch.

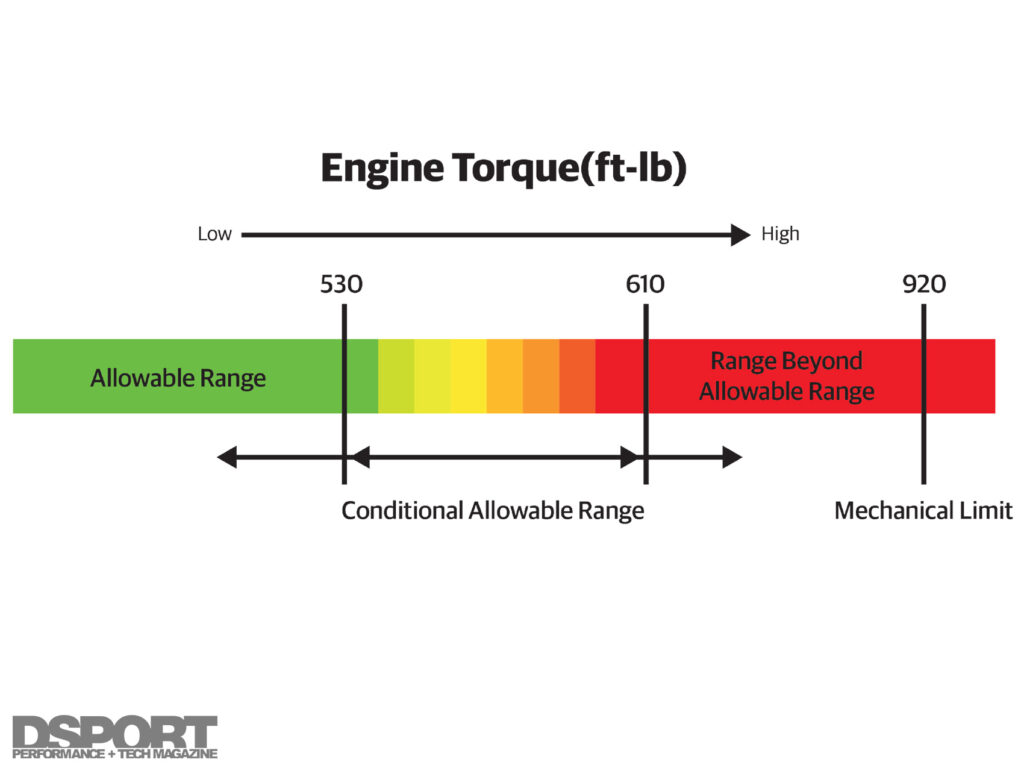

Increasing the clamping force from the pressure plate is something that is possible by upgrading the spring and/or changing the pivot point on the diaphragm spring. When higher-rate springs are used, it is possible that the clutch cover itself will begin to deform or distort when the clutch pedal is pressed. To avoid this possibility and to save some weight, HKS decided to make the clutch cover from high-strength aluminum that won’t deflect like a stamp steel cover. HKS also selected the upgraded diaphragm spring to deliver just the right amount of clamping force for the application. The result is a pedal that has OEM level effort yet a positive feel for accurate control. In choosing the friction material for the HKS LA series of clutch, a high-quality, semi-metallic woven, full-face material was selected. The composition of the material provides higher-fade resistance than OEM materials with a coefficient of friction on the upper end of any organic/semi-metallic material. Up to about 380lb-ft of torque, a HKS LA single clutch kit can deliver excellent performance. Above that level and up to 610lb-ft of torque, the HKS LA twin-disc clutch is the preferred choice.

Converting Torque Capacity to Horsepower Capacity

Performance enthusiasts are obsessed with horsepower. Horsepower at the wheels, horsepower at the flywheel, horsepower per cylinder or horsepower per liter, we hear it all. While we are all guilty of having a horsepower fetish, the reality is that knowing the peak torque output of an engine is much more useful with proper parts selection. Peak torque output is directly proportional to peak cylinder pressures inside the engine. Peak cylinder pressures affect the requirements for the piston, rod and crank strength as well as the head gasket and head fastener requirements. Outside of the engine, an engine’s peak torque output also establishes the requirements for the clutch and driveline strength.

Admittedly, few import engine builders say or brag about building an engine combination to produce a certain amount of torque. “Club DSPORT builds a 1000+whp, 10,000RPM RB26” is usually the headline not “Club DSPORT builds a 525ft-lb, 10,000RPM RB26”. In fact, an RB26 engine making 525lb-ft of torque at 10,000RPM makes 1,000 horsepower, so they are one in the same in some cases. However, an engine that produces 525lb-ft of torque at 6,500RPM only produces 650 horsepower. While these two engines produce significantly different amounts of horsepower, they have the same clutch torque capacity requirements as they both produce 525ft-lb of torque.

The Bottom Line

HKS set out to develop a clutch that behaved like an easy-to-drive OEM clutch yet had the torque capacity to support some seriously modified engines. Combining the latest technologies along with the vast experience allowed Japan’s original performance parts manufacturer to accomplish this goal. The R34 GT-R fitted with this clutch was as easy to drive as when it had its OEM clutch, yet it could support up the 800whp and 525lb-ft of peak torque generated without a hiccup. While it will be some time before we get an idea of clutch longevity, the formula that HKS used in this clutch recipe should provide some exceptional results. Stay tuned.