What? Where? When? and Why?

DSPORT Issue #251

Text by Michael Ferrara

Dollar for dollar, there isn’t another “power adder” that can deliver the power increases of a nitrous-oxide system. In the early days of the import performance movement, hidden “dry” single nozzle nitrous kits were the reason why a few cars were killing it at the street races. Whether the bottle was dressed up to look like a passenger, built into a baby seat or hidden under the dash, having the ability to “squeeze” often decided the winner and the loser of the race. While the popularity of nitrous oxide may never again realize the peak it enjoyed during the Fast & Furious heyday, there are probably several benefits your performance combination could realize with the right nitrous oxide strategy. In DSPORT’s Nitrous Basics and Beyond series we first establish a solid foundation explaining the ins and outs of nitrous oxide power adder systems. Building on this foundation, we will take a close looks at all of the components in a nitrous oxide kit and show the differences between low-cost and premium components. Finally, we will look at advanced nitrous oxide delivery systems and the control systems that allow the assembly of a truly 21st-century nitrous oxide system. By the time we complete the series, you’ll be able to configure the ideal nitrous oxide strategy for reliable performance gains.

What’s the cost?

For under $400, you can purchase a basic nitrous oxide single-fogger wet kit with a 10-pound bottle to add up to 150hp on just about any fuel injected vehicle. A premium system with carbon-fiber bottle, high-flow bottle valve, premium solenoids and premium nozzles can easily take a system over the $1,000 mark. Add in additional stages or a custom “push” configuration and you may be in the neighborhood of $3,000 or more. On simple budget systems, no other power adder can touch the bang-for-the-buck proposition. Even on the more-expensive premium and custom systems, the cost is still way below what is spent on most other power adders. As for the nitrous oxide itself, depending on where you live and where you purchase the nitrous+ or other motorsports formulated nitrous oxide, you are likely to pay between $4.00 and $7.00 per pound. This leads us to the next obvious question, how long will the bottle of nitrous oxide last?

How Long Does a Bottle Last?

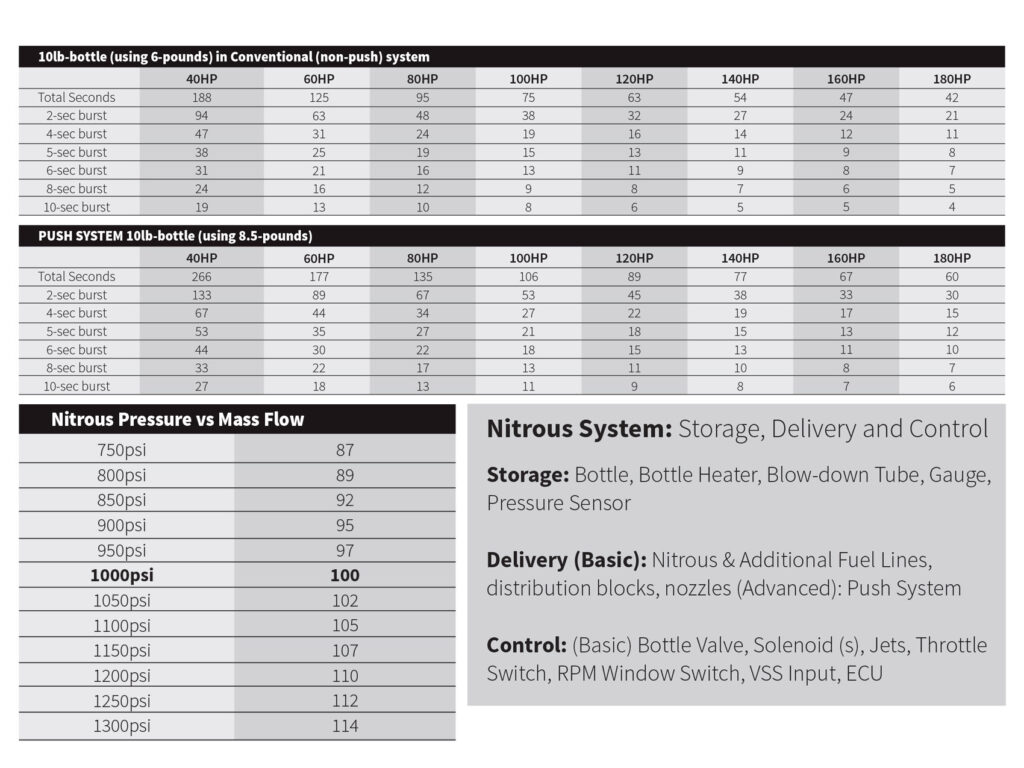

If you are wondering just how long that topped off 10-pound bottle will last before needing to be refilled, it is dependent on just three factors: 1) the size of the nitrous oxide bottle in the system; 2) the amount of the “shot” or additional horsepower being delivered by the nitrous oxide system; 3) whether the nitrous oxide configuration is conventional or a “push” system.

The bigger your bottle, the longer it will last. While the most popular bottle used with nitrous oxide kits is 10-pound. The are also 12-pound, 15-pound and even 20-pound bottles available. In addition, you can run multiple bottles if that fits your vehicle better. When you are running a 10-pound bottle, you will probably get good performance from the first 6 pounds of nitrous oxide and you will start to see a drop off in performance as you start using up the last 4 pounds in the bottle. We will get into the reasons and solutions for this dilemma later in the series. For now, we are just setting a proper expectation level for the useful amount of “squeeze” time you will have.

The amount of squeeze time is also dependent upon the magnitude of the “shot” being delivered by the nitrous oxide power adder. When you are delivering twice the amount of nitrous oxide to make twice the horsepower gain, you will only get half of the amount of time. With a small 40-horsepower shot, a 10-pound bottle would deliver about 188-seconds of “squeeze” time (using up 6 pounds of nitrous oxide in the bottle). An 80-horsepower shot, would cut the time for a 10-pound bottle to use 6 pounds up to 95 seconds. A 160-horsepower shot, would deliver only 47 seconds of squeeze time. We have included a chart that equates squeeze time to shot magnitude for a 10-pound bottle. All the time estimates are based on the assumption that it will take 0.8 pounds of nitrous oxide per 1,000 horsepower per second.

While conventional nitrous oxide system configurations will always drop off in performance as the mass of nitrous oxide remaining in the bottle approaches 35-percent of less of the total capacity, using a “push” nitrous oxide system will allow about 85-to-90 percent of the nitrous oxide in the bottle to be used before a drop in performance is realized. Since there isn’t currently a readily available push system for nitrous oxide systems, these systems are usually only found on those that are experts. Don’t worry as you will be an expert by the time we finish this series and you can see if a push upgrade makes sense for your application.

What are the Components of a Nitrous Oxide Power Adder System?

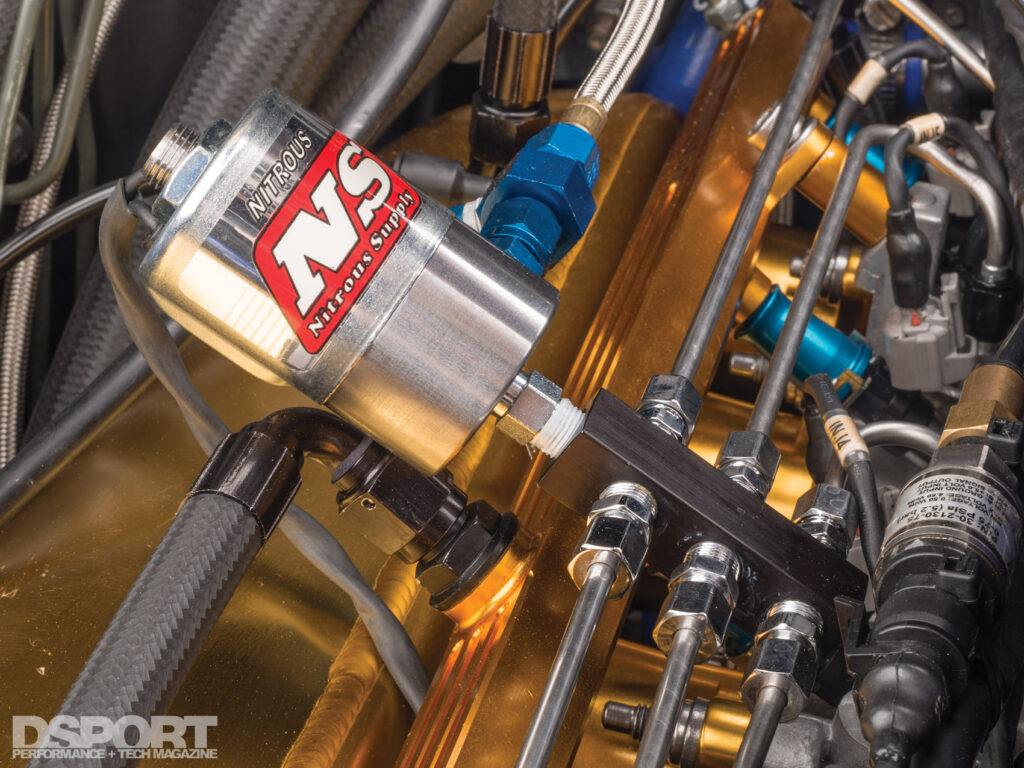

All the components in a nitrous oxide system can be placed into three major categories: Storage, Delivery and Control. In the storage category, all nitrous oxide systems will contain a bottle to hold the nitrous oxide. To ensure that the nitrous oxide is under the proper conditions, a nitrous oxide pressure gauge and or a pressure-sensor tied into the engine management system or datalogger should be employed. Bottles must be correctly oriented and fastened with the proper bottle brackets. Depending on the bottle location in the vehicle, a blow-down tube may also be required to provide a proper escape path if the high-pressure relief valve gets tripped. For conventional nitrous oxide systems (non push type), a bottle heater is often added to keep the bottle heated to a temperature that delivers the desired bottle pressure for the nitrous delivery system.

In convention “dry” nitrous systems, the delivery system will include a bottle valve, main line from the bottle to the nitrous solenoid, the nitrous solenoid, the solenoid to distribution block line, the distribution to nozzle line and the nozzle. Some systems will use a single nozzle or a plate under the throttle body while others will used multiple nozzles. Systems that use one nozzle per cylinder are termed direct port systems. Wet systems will include all of the above for the nitrous component, but they will also have an adapter tap to a fuel supply, lines from the fuel supply to the fuel solenoid, a fuel solenoid, line from solenoid to the nozzle. Wet systems are usually more expensive than dry systems as more components are in the system.

While we included the bottle valve under the distribution category, it can also be considered part of the control system. The most basic and primary determinant of nitrous oxide system activation is the bottle valve. When closed, no nitrous oxide can be delivered to the system. When the bottle valve is open, the main control of nitrous oxide (and additional fuel on wet systems) falls under the control of the solenoids. A solenoid is nothing more than an electronically controlled valve that will allow flow through its valve when the coil is energized. The rest of the control system simply focuses on what conditions need to be met in order for the solenoid to be able to be activated. Nearly all nitrous-oxide systems will contain a main arming switch. This is the switch that controls the power delivery to the solenoids. When this switch is “armed”, a positive 12 volts is supplied to one of the two wires on the solenoid. If the other wire on the solenoid sees a ground signal, the coil of the solenoid will energize and the valve in the solenoid will open allowing nitrous oxide or fuel (fuel solenoid) to flow. The most basic control strategy for a nitrous system is to install a microswitch on the throttle to ensure that the solenoids do not energize unless there is a full-throttle condition. Another good threshold limiter is an RPM window switch which sets the range of acceptable engine speed (RPM) for activation of the system. Ultimately, the ”jets” of the nitrous system will dictate the maximum amount of nitrous (and fuel on wet systems) that will be delivered when the system is activated.

Nitrous Controllers

If you have a modern engine management system on your performance vehicle, chances are that it can provide 21st century nitrous oxide system control. There won’t be a need for throttle switches, RPM window switches or anything besides a system arming signal that is sent to the ECU to let it know you want to squeeze when the right conditions are met. In most stand-alone ECUs, you will be able to set a throttle safety (i.e. don’t activate unless throttle is at least 95 percent), an RPM window (i.e. don’t activate below 3,500RPM or above 7,000RPM), a boost limit (i.e. shut off the nitrous oxide system if this boost pressure is reached), a speed window (i.e. don’t activate under 5MPH or above 150MPH) and that’s just for starters. When the parameters are met, most aftermarket ECUs can also do a new timing table to retard a set amount of ignition timing to compensate for the accelerated burn rate realized when nitrous oxide and additional fuel are injected. For dry systems, most aftermarket ECUs can also increase fuel delivery to the cylinders to get the proper nitrous oxide to fuel ratio. The right stand-alone ECU can do all of the above and more including even doing progressive nitrous oxide delivery by pulsing the solenoid to run at a 20-to-100 percent duty cycle.

While there are many nitrous oxide controllers, they all have extremely limited capabilities compared to what is offered in a decent stand-alone engine management system. DSPORT is currently working with a few companies to see some 21st century nitrous controllers for those needing superior control but not having the access to a stand-alone engine management system. Hopefully, some of these will come to market in the next year or two.

AutoMagic Nitrous Oxide

One area where a little nitrous oxide is making a big difference is with the big turbo/auto transmission community. With an automatic transmission, the stall speed on the torque converter is dependent upon the torque output of the engine. When an engine makes more torque, the stall speed (engine RPM seen when the throttle and brake are simultaneously floored) will increase. When an engine doesn’t make a lot of torque off or at low boost (what happens when a big turbo is put on a small engine), the only way (without using nitrous oxide) to make the stall speed high enough to be able to launch the vehicle is to make the converter less efficient by increasing the slip percentage. However, by using a small shot of nitrous oxide an instant amount of torque can be realized at the engine which increases stall speed and boost which again increases stall speed and eventually the desired launch stall speed can be realized without having to rely upon a super “loose”, low-efficiency, high-slip converter. Instead, a more efficient converter can be used which delivers less loss, lower trans fluid temps and higher trap speeds. These systems are found on just about every DSM set up with an automatic thanks to the efforts of Kiggly Racing and others that figured out the ideal control of the nitrous oxide system to get the desired effects.

Little Shot, Lotta’ Power

If you have a performance combination with a big turbo that already gets you to the power target you desire, you may think that you wouldn’t benefit from a shot of nitrous oxide. You’re wrong! The biggest benefits that we have ever realized from nitrous oxide systems were on a “big turbo” setup.

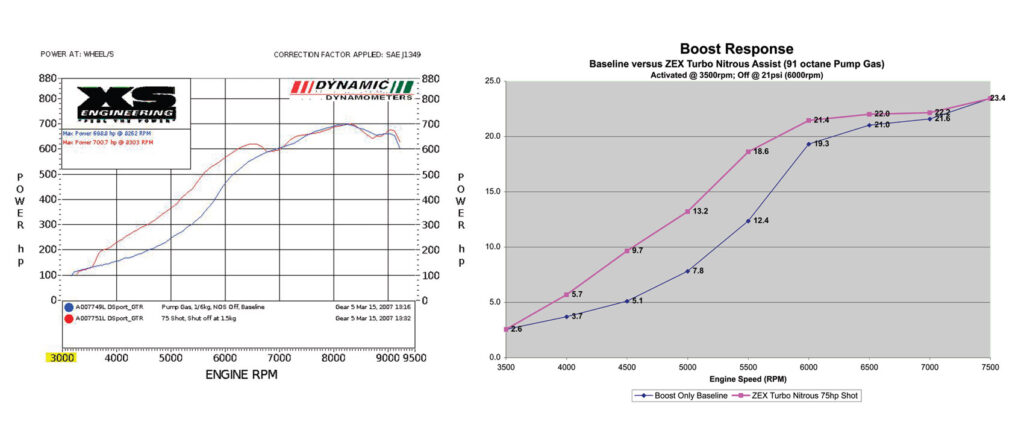

About 15 years ago, we tested a single nozzle wet system on our Project RH8 GT-R. The RB26 in the vehicle was still running on pump gas most of the time with a set of big IHI TCW76 turbos. Without nitrous oxide assistance, the engine would make 700 horsepower to the wheels at 8,000RPM running 22psi of boost pressure. While that was an impressive peak horsepower number on 91-octane pump gas, the torque curve didn’t reach peak torque until 6,500RPM. With just a 75-shot from the single nozzle wet nitrous oxide system, peak torque was able to come 1,000RPM sooner (at 5,500RPM). Best of all, that “75” shot actually delivered an additional 150 horsepower at 5,500RPM since it added 75 horsepower from the nitrous-oxide along with 75 additional horsepower from the increased boost pressure (from a 12.4psi to 18.6psi at 5,500RPM).

To give an idea of the difference is response time, we conducted test pulls from 3,200 RPM to 8,000RPM with and without the nitrous oxide system activating at 3,500RPM. With no nitrous oxide assistance, it took 15 seconds for the engine to accelerate from 3,500RPM to 8,000RPM in the test gear. With the nitrous oxide system kicking in at 3,500RPM, it took only 7 seconds for the engine to accelerate over that same range.

To make sure that you do not exceed the maximum safe cylinder pressures for your engine combination, all you need to do is set a boost limit for the nitrous oxide system that shuts the system off once the original peak torque is realized. We will show you more of this tuning in future installments of Nitrous Basics and Beyond.

The Bottom Line

Since WWII, nitrous oxide has been used as a power adder for internal combustion engines. Used originally on aircraft to gain performance at high-altitudes, nitrous oxide allows an engine to combust more air and fuel than would normally be possible. Today’s technology allows one to extract more reliable performance from nitrous oxide than ever before. While many performance combinations can reach the horsepower target through a high-flow turbo targeting high boost levels, most “big” turbos have less than stellar boost response. The result is an engine that lags until higher engine speeds. Big turbos on automatic equipped vehicles can also make converter setups a major challenge. A little shot of nitrous oxide can be the ultimate solution to getting a designed stall speed without relying upon an ultra loose converter. Hopefully, we have your attention and in our next installment we will be getting you to plan out the ultimate nitrous oxide system solution for your vehicle. Stay tuned.