Imagine standing at the cargo door of an airplane 13,000 feet in the air. You brace yourself as you are about to make your first solo skydive. You feel the rush of adrenaline sweep through and the last thing you want running through your mind is whether your parachute is packed properly. If you were precautious, then this thought would not cross your mind because you did a thorough job checking your parachute before you even stepped foot on the plane. Just like skydiving, driving a car at a track day can give you the thrill of a lifetime, but without taking the necessary precautions your day of fun could possibly go terribly wrong.

Text by Robert Choo

DSPORT Issue #200

Performance brake calipers can increase the piston area to increase brake torque.

Brake System

Although often neglected, one of the most important things to check on the car are the brakes. The last thing you want to happen when barreling 100+ mph down the front straight is the brake pedal going to the floor and you are unable to slow the car down before the next turn.

The simplest upgrade you can perform to increase braking performance is changing the brake fluid with a high-quality fluid. A common problem most novice track enthusiasts experience is a spongy brake pedal after a couple of laps on the race track. This is caused by the boiling of the brake fluid which creates air bubbles in the fluid. Unlike brake fluid, the air bubbles can compress under pressure as the brake pedal is pressed. Without fluid pressure, the caliper/drum pistons are not expanding to push the brake pads against the brake disc/drum, in turn the car is not able to slow down. Most high-performance brake fluids can sustain a higher boiling point and are designed to endure the increased temperatures that occur trackside. The higher temperature capacity of the fluid reduces the chances of it boiling. All brake fluids are hygroscopic (absorbs moisture from the air) and as the brake fluid absorbs more moisture, the boiling point decreases. Depending on how often the vehicle is tracked, replacing the brake fluid at least once a year is highly recommended.

The simplest upgrade you can perform to increase braking performance is changing the brake fluid with a high-quality fluid. A common problem most novice track enthusiasts experience is a spongy brake pedal after a couple of laps on the race track. This is caused by the boiling of the brake fluid which creates air bubbles in the fluid. Unlike brake fluid, the air bubbles can compress under pressure as the brake pedal is pressed. Without fluid pressure, the caliper/drum pistons are not expanding to push the brake pads against the brake disc/drum, in turn the car is not able to slow down. Most high-performance brake fluids can sustain a higher boiling point and are designed to endure the increased temperatures that occur trackside. The higher temperature capacity of the fluid reduces the chances of it boiling. All brake fluids are hygroscopic (absorbs moisture from the air) and as the brake fluid absorbs more moisture, the boiling point decreases. Depending on how often the vehicle is tracked, replacing the brake fluid at least once a year is highly recommended.

Next on the list of braking performance upgrades to address are the brake lines. Most OEM brake lines are made from rubber. Like all rubber components, the brake lines can dry out and lead to failure when braking demands are increased at the track. Upgrading to an aftermarket stainless-steel brake line kit can not only reduce the possibility of brake line failure, but also increase performance. Unlike the rubber lines that can expand slightly under braking pressure, stainless-steel brake lines exhibit minimal expansion under pressure. In turn, a more positive brake pedal feel and better braking performance can be achieved.

To finish prepping the brake system, do not forget about the brake pads. The brake pads are responsible for clamping against the brake rotor/drum to slow the vehicle down and eventually bring it to a stop. Factory brake pads are designed to operate at low temperatures to allow the braking system to work effectively even in very cold climates. Unfortunately, most factory brake pads cannot handle the increased temperatures exhibited at the track and often times the brake pads overheat resulting in brake fade. Unlike factory pads, high performance brake pads can operate at a much higher temperature and still slow a car down even if temperatures reach above 1000+ degrees. It is common to see temperatures soar that high at the track, so investing in a set of high performance brake pads is ideal.

Drilled and slotted brake rotors allow the gases produced from the friction between the pads and rotors to escape. This prevents the brakes from heating up, thus increasing stopping performance.

With the addition of performance brake fluid, stainless steel lines and high performance brake pads, the vehicle braking performance can significantly increase. However, it is a good idea to inspect all braking components and ensure they are working properly. Inspecting all the components of the braking system (brake master cylinder, caliper piston, brake fittings, hard lines, etc.) for leaks is extremely important. Another area to pay close attention to is the caliper guide pins. A sticking or frozen guide pin can not only affect braking performance but also can cause the vehicle to pull towards one direction under heavy braking. Caliper guide pins should be cleaned and greased regularly to prevent dirt and debris from building up.

Preflight Checklist

With the addition of performance brake fluid, stainless steel lines and high performance brake pads, the vehicle braking performance can significantly increase. However, it is a good idea to inspect all braking components and ensure they are working properly. Inspecting all the components of the braking system (brake master cylinder, caliper piston, brake fittings, hard lines, etc.) for leaks is extremely important. Another area to pay close attention to is the caliper guide pins. A sticking or frozen guide pin can not only affect braking performance but also can cause the vehicle to pull towards one direction under heavy braking. Caliper guide pins should be cleaned and greased regularly to prevent dirt and debris from building up.

Inspecting all suspension components prior to track day is vital. Always check for leaking shocks, torn boots, worn bushings, broken parts, and anything that looks suspicious.

Track Checklist

Here is a list of items you should consider bringing with you to the track to make your experience more enjoyable.

• Basic tool box

common size wrenches, sockets, screwdrivers, pliers, etc.

• Engine oil

• Brake fluid

• Distilled water (for radiator)

• Paper towel/rags

• Glass cleaner

• Tire pressure gauge

• Disposable gloves

• Torque wrench

• Flashlight

• Drinking water

• Folding chair

• Hat

• Duct tape/painter tape

• Jack and jack stands

• Service manual

• Snacks

Suspension Components

There is an old adage that goes, “whatever that you think will break will break at the track.” The most common thing to break at the track is a suspension component. It is common to see much higher g-forces at the track than your normal everyday commute to work. This increased stress on the suspension components can lead to failure. The inner and outer tie-rods are known failure points and should be inspected regularly for torn boots, leaks and excessive play. It is good practice to always check all suspension bushing for cracks and also re-torque all suspension nuts and bolts to the vehicle manufacture setting. As added insurance, using a small amount of blue thread locker liquid on each fastener will help decrease the chances of the nut or bolt loosening.

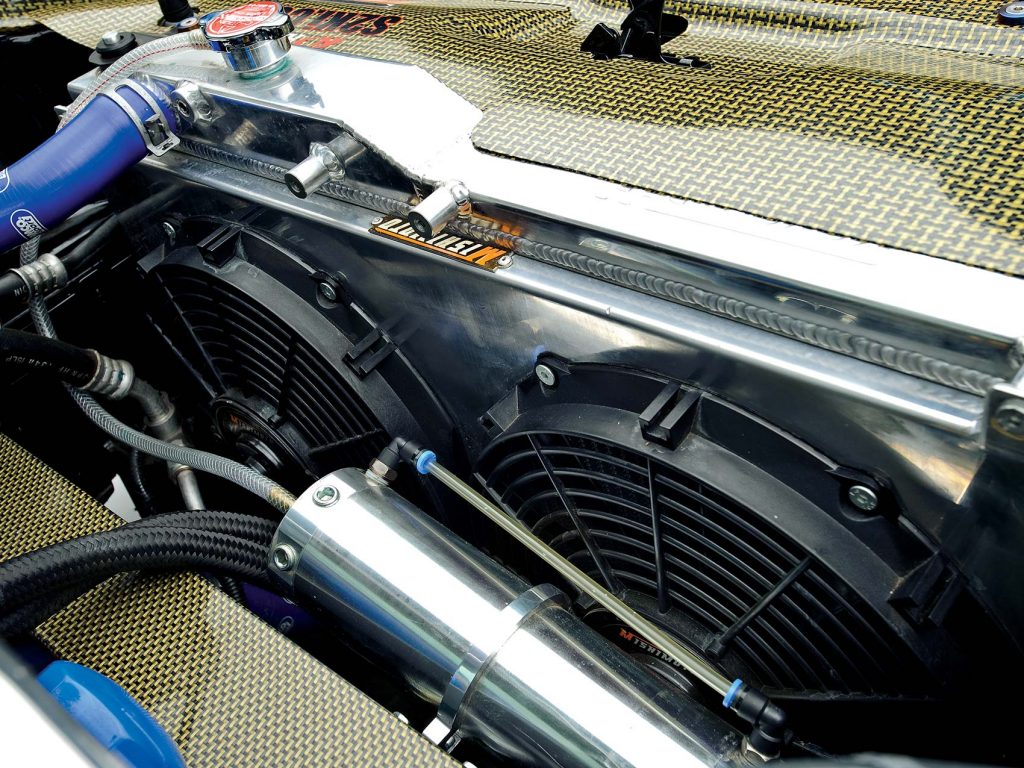

Get in the habit of regularly checking your coolant level, as well as the condition of all radiator hoses. Any splashes around the engine should be addressed prior to the track day.

Cooling System

At the track, the engine and transmission will experience extreme loads of pressure that can generate a lot of heat. It is the responsibility of the engine cooling system to help maintain an ideal operating temperature at all times. Similar to the brake lines, the coolant hoses can dry and crack overtime, causing leaks in the system. In order to have the cooling system function at its optimal level, replacing the rubber hoses with nylon reinforced silicone ones and adding a cooling system additive will help prevent the cooling system from failing. There are several manufacturers that offer nylon reinforced silicone radiator hoses that decrease the chance of a ruptured hose. In addition to replacing the hoses/lines and fluid, a cooling system additive can aid in reducing coolant temperature. The cooling system additive is an affordable way to prevent overheating from occurring. Replacing the coolant on a vehicle every two years will ensure the engine operates at an ideal temperature.

Before going on the track, check the tire tread to ensure it has at least 2/32” of tread. Be sure to check the outside, the middle, and the inside tread.

Powertrain

As a car enthusiast, there is no better feeling than the rush from stepping on the accelerator pedal while hearing the engine scream to redline. Now imagine doing that for 20 to 30 minutes straight! That amount of time can put a large load of strain on both the engine and transmission. Every part of the powertrain will be tested to its limits and making sure it is running at its peak is crucial. Using a good quality synthetic oil in both the engine and transmission will help keep all the moving parts properly lubricated. In addition, if the engine or transmission is leaking, fixing it prior to taking it to the race track is an absolute must. The oil can leak onto the racing surface at the track which can potentially cause a very dangerous situation for yourself and others racing around you. Any oil leakage on the track can cause drivers to spin out and caution flags to wave. Everyone is instructed to leave the track until the oil on the track is properly cleaned off. This takes a lot of time out of track day, so make sure there are no leaks before you go.

Tires

It is a misnomer that the vehicle needs to be equipped with racing tires before taking it to the track. It is possible to track on any type of tires, and yes, that includes all season tires as well. However, there are some things to consider before taking your parents’ minivan on the racetrack. Check each and every tire for punctures from any sharp objects. A compromised tire can lead to a blowout, which can be dangerous when pushing the vehicle to the limits. It is also important to check the sidewalls for cuts, cracks or dry rot as any of these can lead to potential breakdown. The tires will wear faster at the track and inspecting the tread depth of a tire is crucial. A tire should have at least 2/32” of tread depth to ensure the vehicle does not wear the tires to the cords after a day of driving at the track.

Everyone is instructed to leave the track until the oil on the track is properly cleaned off. This takes a lot of time out of track day, so make sure there are no leaks before you go.

Hot Lap

As a car enthusiast, there is absolutely no better way to have fun with your car than driving it at the racetrack. Make sure that your car is ready to endure a day of racing by following the guidelines above. In doing so, an adrenaline-filled day at the racetrack is guaranteed.