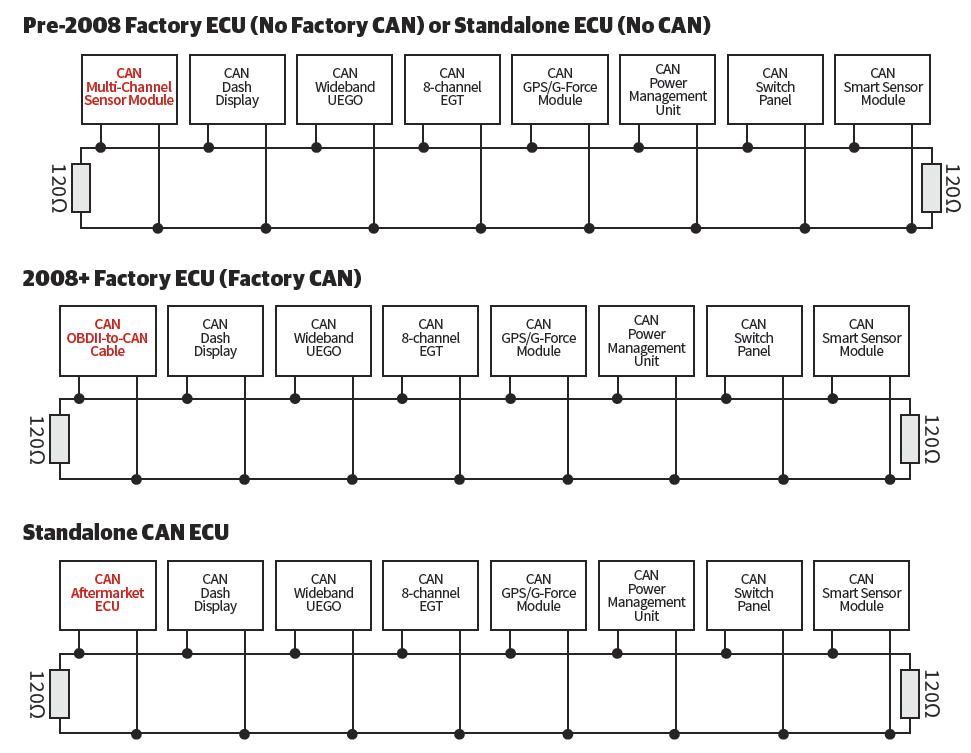

If you are old enough to have used computers before the invention of the USB port, you probably really appreciate USB. Before USB, hooking up any external device to your computer required the assignment of a hexadecimal address to a serial port or parallel port that needed to have unique assigned IRQs. If you messed up in your BIOS settings and put two devices on same IRQ, neither one would work right. The advent of USB eliminated this frustration forever and established a true plug-and-play solution. What USB did for computers, Controller Area Network (CAN bus) technology is doing for vehicles. Since 2008, any car sold in the USA has been required to have CAN bus. CAN bus or “CAN” technology is also present in most modern day stand-alone engine management systems. For pre-2008 vehicles not using an aftermarket CAN-compatible engine management system, there are multiple-channel CAN sensor modules that can be retrofitted in earlier vehicles to establish a CAN bus for a CAN based dash. By taking a look at pre-CAN and CAN-based communication on a vehicle, it’s easy to see why both the OEMs and performance aftermarket are getting on the bus.

Text by Michael Ferrara // Photos by Joe Singleton and Bassem Girgis

DSPORT Issue #209

I Know It, But I’m Not Telling You

Before CAN integration, vehicles using multiple control-units had to each have its own set of sensors. If both the engine control module (EMC) and the transmission control module (TCM) wanted to know engine coolant temperature, there would be two separate temperature sensors placed on the engine and dedicated wires would run from each sensor to each ECU. Sometimes a single sensor’s output could be shared across multiple control units but even that still required independent wiring from the sensor to each control unit. Even when one controller in the vehicle had received a sensor signal, processed it and determined a value, there was no way of it telling another controller in the vehicle. Before CAN, multiple control units on a vehicle had an “I know it, but I’m not telling you” attitude.

All modern aftermarket stand-alone engine management systems have CAN-bus capabilities. Since external CAN modules can deliver wideband UEGO data, on-board UEGO inputs are disappearing.

Let Me Tell You Something

Instead of keeping information to itself, what if each control unit sent out a message to other control units in the area on a shared network telling them everything it knew the instant it was known. Going back to our original example, the engine control unit could transmit everything it knows to this area network. Parameters including but not limited to engine speed, engine load, coolant temperature, gear position, vehicle speed and throttle position could be broadcast to this CAN. Since the transmission control module is tied into this network, it would know all these engine parameters without having a dedicated or even shared sensor tied into it. Since the communication on this network is two-way, the transmission control module could broadcast information it gathers to the network. By sharing information such as transmission fluid temperature, transmission fluid pressure, torque converter lock-up status and more, any controller tied into the network would know this information. On a CAN based system, an ABS controller may get 80-percent of its information off the CAN bus while the remaining 20-percent comes from dedicated wheel speed sensors and accelerometers. Any information from any unique controller can be shared on the network. In addition to dedicated controllers on the CAN bus, there may also be smart sensors providing information to the network. Whereas a conventional or “dumb” sensor requires a host computer to interpret its output into a parameter, a smart sensor contains its own processor that outputs a full-fledged CAN message instead of a digital or analog output. On a CAN system, every controller and every smart sensor will be telling the network “let me tell you something.”

Data wins races. While the AEM Infinity Series-7 EMS offers more analog and digital inputs than most ECUs, a serious racecar may need more. Thankfully, the Infinity EMS systems can us CAN to get more information from CAN modules on the CAN system.

The CAN Advantage

One of the big advantages of a CAN bus system from an OEM manufacturer is the ability to reduce overall system cost and complexity. A CAN bus eliminates redundant sensors and reduces wiring on the vehicle. Since OEMs may use different suppliers for different controllers, requiring all of the controllers to speak the same CAN language eliminates compatibility issues.

Our first taste of the power of CAN came with the install of the AEM VDM. Plugging in one DTM connector to our CAN bus delivered us time, GPS and 3-axis acceleration data.

OEM CAN Use

On a newer vehicle, there are many more controllers than you might think. Of course, there is the engine control until and the transmission control unit (if it’s not a manual transmission vehicle). In addition to those primary controllers, there could be control units for airbags, ABS, electric power steering, power windows, cruise control, electric cooling fans, fuel pump, climate control, dash display, vehicle immobilizer, seat belts, windshield wipers, TPMS and just about anything else on the vehicle can be tied into the CAN bus. One of the reasons why the 8-speed automatic transmission works so well on the new Supra is thanks to the information sharing between the engine and transmission controllers on the CAN bus. The CAN bus has also made diagnostics significantly better than pre-CAN. With the right scanner tapped into the CAN bus, more information is available to the technician than ever before.

CAN First Impressions (Aftermarket)

When CAN first started rolling out in vehicles in 2008, the aftermarket was a bit slow to embrace. In fact, many in the performance aftermarket believed CAN was going to be a hurdle to performance. Early on, aftermarket standalone ECUs that had no CAN compatibility were installed in CAN vehicles with horrible results. Since the aftermarket ECU couldn’t receive or broadcast any CAN information to the CAN bus on the vehicle, many of the other control units on the vehicle stopped working without the factory ECU in place. Plug-and-play standalone ECUs for these newer vehicles weren’t available for quite a number of years. Fortunately, the performance aftermarket is embracing CAN and exploiting its merits. In fact, companies like MoTeC offer aftermarket ECUs that fully integrate with the vehicle’s CAN bus. Today, having a vehicle with a factory CAN bus is seen as a positive instead of a negative.

When CAN first started rolling out in vehicles in 2008, the aftermarket was a bit slow to embrace. In fact, many in the performance aftermarket believed CAN was going to be a hurdle to performance. Early on, aftermarket standalone ECUs that had no CAN compatibility were installed in CAN vehicles with horrible results. Since the aftermarket ECU couldn’t receive or broadcast any CAN information to the CAN bus on the vehicle, many of the other control units on the vehicle stopped working without the factory ECU in place. Plug-and-play standalone ECUs for these newer vehicles weren’t available for quite a number of years. Fortunately, the performance aftermarket is embracing CAN and exploiting its merits. In fact, companies like MoTeC offer aftermarket ECUs that fully integrate with the vehicle’s CAN bus. Today, having a vehicle with a factory CAN bus is seen as a positive instead of a negative.

Aftermarket Performance CAN

What if you could add a new controller to your vehicle and it could know everything on the CAN-bus and while sharing its information to the area network? That is today’s reality. CAN bus communication is a standard feature on nearly all modern aftermarket engine management systems.

The best tuners in the world understand that A/F ratio only tells part of the story. Having one EGT sensor per cylinder is essential for optimizing the cylinder-to-cylinder balance of the tuning.

Opening the CAN of WhoopAss

Our first stand-alone engine management experience with CAN was on our Project RH8 GT-R. This vehicle, which was born way before CAN-bus technology had been adopted on all vehicles, was one of the original test vehicles to run an AEM Electronics Infinity engine management system. Since a custom wiring harness was made for this installation, we became quite familiar with all the sensor inputs into the engine management system as well as the control outputs from the engine management system. When you undergo the wiring harness design experience, you’ll soon appreciate all the data you are able to gather. Since having more data leads to better tuning, you’ll soon find yourself wanting to add a sensor to monitor this or that. Although the Infinity Series-7 engine management system had more inputs available than nearly any other aftermarket ECU (6 temp, 17 analog, 8 digital, 6 VR), I eventually ran out of analog channels to feed more data into the system. I only ran three of the four channels of EGT, since I had 14 of the analog inputs already occupied. Just like the world of computers before USB, adding a new sensor required assigning the proper channel, populating the right pin at the connector and hopefully not messing up anything else in the process. Fortunately, expanding on the system through CAN helped us meet our needs.

The first CAN device added to our AEM’s CAN-bus was the AEM Electronics Vehicle Dynamics Module (VDM). While you may think of this device as being suited only for track vehicles (it can do track mapping), its data is valuable for tuning any vehicle. To install the VDM, a total of just four wires needed to be connected: a switch +12v power, a ground and the two CAN wires. Since a DTM connector was already present on my harness for the CAN, I simply plugged it in. Minutes later the AEM Infinity now had over a dozen additional channels of information being shared on the CAN network thanks to the VDM. These additional channels of information included acceleration and yaw in three directions, GPS location, GPS altitude, GPS speed, and UTC time. Since our GT-R spins all four tires when launched hard, having a GPS speed channel is crucial for tuning the launch. In this way, we can calculate the percent of wheelspin that occurs. Having the time broadcast by the VDM is also handy as this was one channel absent from the AEM Infinity. Being able to log the time makes it easier to identify logged data in the future.

Following the success of this first CAN device/module added to the system, we followed up with putting an X-series Pro Inline 2-channel wideband controller on our CAN. While the AEM Infinity had two on-board UEGO channels, these were not compatible with the latest generation Bosch sensor or the X-series technology. Thanks to this addition, we have fast responding exhaust oxygen sensor readings which allowed us to fine tune throttle response. As with the VDM, installation of the wideband controller was a snap. Many of the current and future standalone engine management systems are completely abandoning on-board UEGO channels. All wideband information for those ECUs will come solely from CAN.

While we haven’t installed it yet, the AEM Electronics 8-channel K-Type EGT CAN module may be our favorite. This unit is going to replace our older AEM 4-channel Thermocouple Amp. The older 4-channel Thermocouple Amp worked well but it used up to four analog channel inputs on the AEM Infinity engine management system. In contrast, the new 8-channel EGT CAN module provides up to 8-channels (16-channels when a second module is added) of EGT readings over the CAN bus. Since the EGT CAN module doesn’t use any of the Infinity’s analog inputs, these inputs can be used for other purposes. In our particular case, we will now be able to add three more analog inputs into the Infinity (these three channels were previously used by the older 4-channel thermocouple amp). Since the EGT CAN module freed up three analog input channels on the Infinity, we are going to be adding a 2000psi pressure sensor to monitor nitrous-oxide bottle pressure and a 5000psi pressure sensor to monitor the air pressure in the “push” bottle for the nitrous-oxide system. While we haven’t yet dedicated the remaining channel to a use, it’s only a matter of time before we do. In fact, maybe it will be for wastegate position.

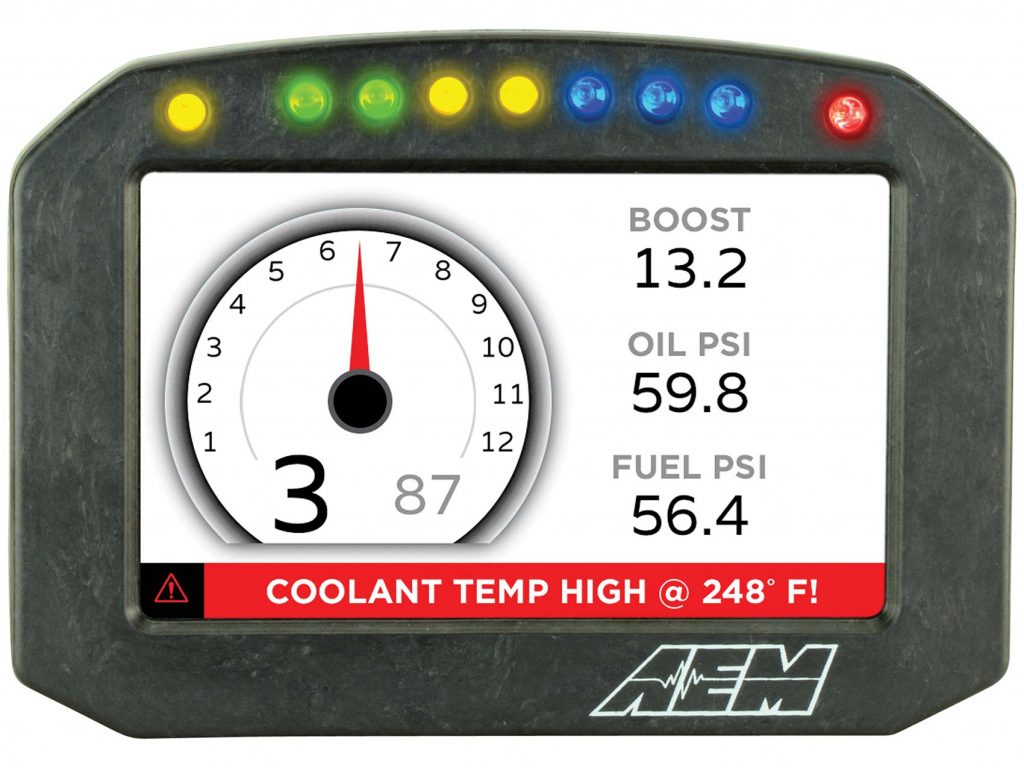

Perhaps our coolest future addition to the CAN system of the Project RH8 GT-R will be an AEM Electronics CD-5 carbon flat panel digital dash display. With a simple connection to the CAN bus, the CD-5 now knows everything each controller on the system knows. Hence, this dash will be able to display any channel from any controller on the CAN bus. While we plan on maintaining the Nismo analog dash for tachometer and speed functions, just about every other important parameter will be displayed on our CD-5 dash display.

Most CAN modules will simply plug into a CAN bus set up with a 4-wire DTM connector. Lambda controllers will require additional wiring for the higher-current heater circuit.

We CAN do it

Tire temperature monitors, fuel flow sensors, vehicle height sensors and shock position sensors are just a few of the many CAN smart sensors we might be adding to our setup in the near future. If knowledge is power, CAN allows all tuners the opportunity to gather more data than ever before. As long as the tuner is smart enough to understand the data, more and more cars should be doing what was once considered the impossible. Stay tuned for our CAN Speed Shop showcasing all of the latest and greatest CAN-based offerings.