IN THE WORLD OF RACING, GOVERNING BODIES ESTABLISH SPECIFIC REQUIREMENTS in order to present a level playing field and ensure safety. In the quest for a championship, some competitors take extra measures in order to gain an edge, pushing the limits and raising the standards. Experienced racers are never suprised by just how far some competitors are willing to go. Cameron Worth, owner of Pettit Racing in West Palm Beach, Florida, exemplifies the driven competitor. Since winning the 1998 GT Championship in the GT2 class with a RX7 FD, his thirst for a new victory could not be quenched. Encouraged by the the Rolex Cup’s head technician Dave Watson, Worth began research and development of a brand-new racing chassis aimed at dominating the Rolex Cup championship.

Text and Photos by Richard Fong

Back To The Drawing Board

Building a state-of-the-art racecar requires intense and detailed planning. Seeking to step up the build of his new chassis, Worth sought the help of Joel Hass at Parametric Solutions during the design phase. Using state-ofthe- art CAD and fluid-dynamics simulation software, the team began working on the new chassis. As a Mazda specialist, Worth decided to build his chassis around the Mazda RX-8 SE3P platform. Pettit Racing proceeded to fabricate the chassis out of 1 ¾-inch OD chromoly tubing with secondary bracing made from 1 ½-inch OD tubing. Fabrication work and design was constantly checked with the racing-series technical advisors to ensure compliance with the rules. With the tube frame complete, Worth outfitted the cockpit with a custom-made carbon-fiber race bucket seat with a rotorshaped head rest. A G-Force Racing Gear 6-point harness was chosen to secure the driver to the race-bucket. In front of the driver, a Competition Data Systems Co-Pilot 2 GPS-datalogger display relays and records engine vitals along with other variables like shock travel, steering angle and throttle position. A SPA Design transmission and differential temperature gauge is positioned to the side of the datalogger.

Building a state-of-the-art racecar requires intense and detailed planning. Seeking to step up the build of his new chassis, Worth sought the help of Joel Hass at Parametric Solutions during the design phase. Using state-ofthe- art CAD and fluid-dynamics simulation software, the team began working on the new chassis. As a Mazda specialist, Worth decided to build his chassis around the Mazda RX-8 SE3P platform. Pettit Racing proceeded to fabricate the chassis out of 1 ¾-inch OD chromoly tubing with secondary bracing made from 1 ½-inch OD tubing. Fabrication work and design was constantly checked with the racing-series technical advisors to ensure compliance with the rules. With the tube frame complete, Worth outfitted the cockpit with a custom-made carbon-fiber race bucket seat with a rotorshaped head rest. A G-Force Racing Gear 6-point harness was chosen to secure the driver to the race-bucket. In front of the driver, a Competition Data Systems Co-Pilot 2 GPS-datalogger display relays and records engine vitals along with other variables like shock travel, steering angle and throttle position. A SPA Design transmission and differential temperature gauge is positioned to the side of the datalogger.

The extensive CAD work comes together with the Mazdaspeed carbon-fiber shell to form a slippery profile designed for aerodynamic excellence.

Making It Stick

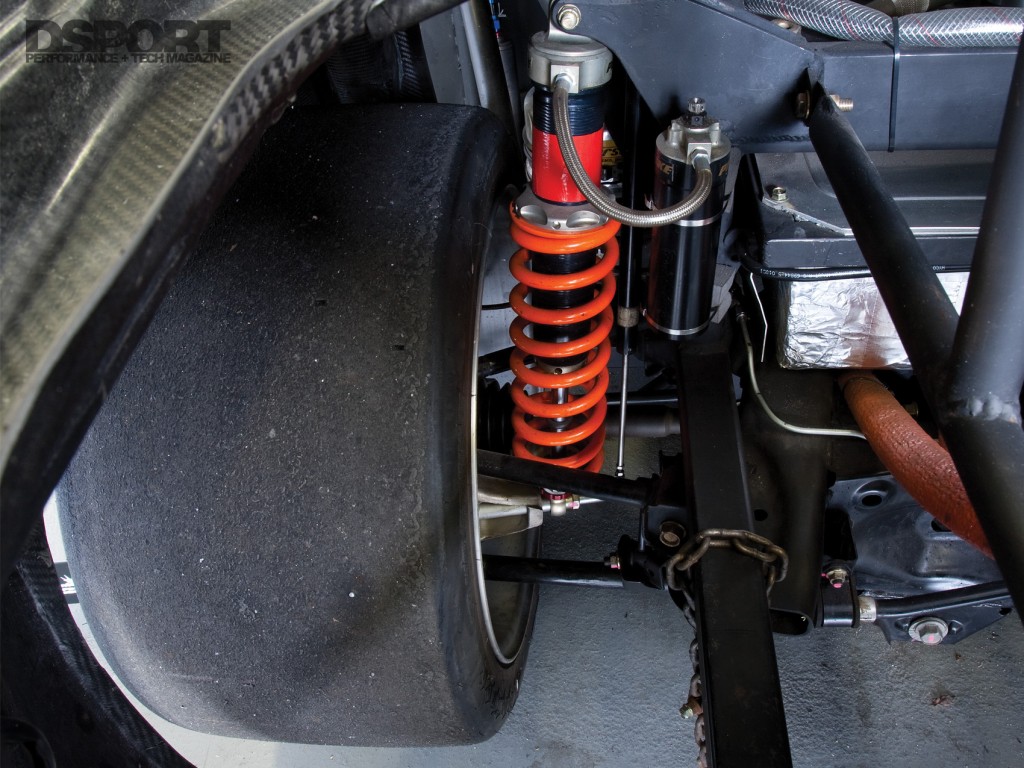

With the completion of the frame, work proceeded on the suspension design. The double-wishbone independent-suspension pieces join the chassis at ideal pickup points to enable the best possible alignment for optimal handling. A Genesis adjustable sway bar complements the front suspension, further improving steering response. Penske 3-way coil-over dampers provide shock absorption at all four corners, while Vogtland springs carry the weight of the chassis. The chassis rolls on a set of Forgeline 18-inch racing wheels wrapped with super-wide Hoosier racing slicks for maximum contact with the track surface. A set of Outlaw 4000 4-piston brake calipers squeeze Hawk Performance brake pads to bleed the speed before corners. Two-piece 13-inch vented rotors provide a large friction surface and dissipate heat to battle against brake fade. Ensuring proper modulation, a Tilton Engineering pedal set delivers hydraulic pressure to the brake calipers through Goodridge steel-braided brake lines. A Tilton Engineering proportioning valve, mounted next to the steering column, enables the driver to make brake-bias adjustments on the fly.

With the completion of the frame, work proceeded on the suspension design. The double-wishbone independent-suspension pieces join the chassis at ideal pickup points to enable the best possible alignment for optimal handling. A Genesis adjustable sway bar complements the front suspension, further improving steering response. Penske 3-way coil-over dampers provide shock absorption at all four corners, while Vogtland springs carry the weight of the chassis. The chassis rolls on a set of Forgeline 18-inch racing wheels wrapped with super-wide Hoosier racing slicks for maximum contact with the track surface. A set of Outlaw 4000 4-piston brake calipers squeeze Hawk Performance brake pads to bleed the speed before corners. Two-piece 13-inch vented rotors provide a large friction surface and dissipate heat to battle against brake fade. Ensuring proper modulation, a Tilton Engineering pedal set delivers hydraulic pressure to the brake calipers through Goodridge steel-braided brake lines. A Tilton Engineering proportioning valve, mounted next to the steering column, enables the driver to make brake-bias adjustments on the fly.

Penske 3-way coilovers with Vogtland springs at all four corners