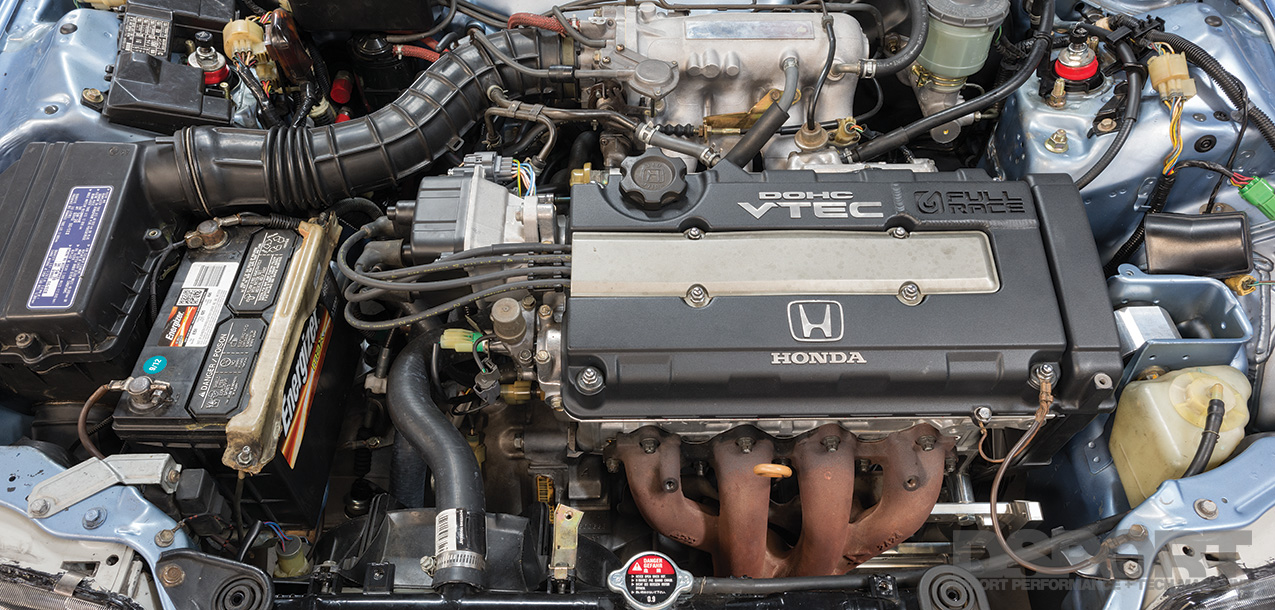

Whether you drive a Honda or not, the term VTEC is something you’ve probably heard of either in a joke, seen in an internet “meme” or plastered on the side of a car accompanied by the letters D, O, H and C. It’s not high horsepower, large displacement or even turbocharged from the factory. However, the B-series engine introduced the world to Honda’s revolutionary Variable Valve Timing and Li Electronic Control (VTEC) technology. VTEC gave the B-series engines the equivalent of two di erent camsha profiles. The first cam profile o ffered low RPM response, good drivability and decent fuel economy. The ECU-controlled VTEC system would then enable a second cam profile (higher lift , longer duration) to activate at higher engine speeds, increasing airflow and horsepower production. This resulted in an engine with one of the highest horsepower-per-liter output at that time.

Text and Photos by Jun Chen

THE “B” DIFFERENCE

The 1.6-liter B16A power plant that first equipped the JDM 1989 Honda Civic and CRX SiR (EF9/EF8) produced a sizable 160 horsepower from the factory (100 bhp per liter), a first for an engine of its size without forced induction. Unfortunately, the U.S. market never received an 88-91 Civic or CR-X with a maximum output greater than 108 horsepower. While a USDM Civic or CR-X may not benefit from the B-series engine from the factory, the modular nature of Honda chassis and engines makes it possible to swap from D to B. With the right aftermarket parts and a budget set aside, you’ll be able to make the move too.

The 1.6-liter B16A power plant that first equipped the JDM 1989 Honda Civic and CRX SiR (EF9/EF8) produced a sizable 160 horsepower from the factory (100 bhp per liter), a first for an engine of its size without forced induction. Unfortunately, the U.S. market never received an 88-91 Civic or CR-X with a maximum output greater than 108 horsepower. While a USDM Civic or CR-X may not benefit from the B-series engine from the factory, the modular nature of Honda chassis and engines makes it possible to swap from D to B. With the right aftermarket parts and a budget set aside, you’ll be able to make the move too.

BUILDING A BUDGET

As with any project, the first thing that should be done is to decide on the overall budget of the build. From a high-mileage engine that’s simply thrown in to a completely rebuilt engine with forged internals and an upgraded transmission, a B-series swap can vary greatly in both price and performance. Simply put, you need to come up with the total budget that you can allocate for the swap. Then and only then can a parts list be put together.

[pullquote]FOR THIS PROJECT, WE WILL HIGHLIGHT A CARB-LEGAL ENGINE BUILD[/pullquote]For this project, we will highlight a CARB-legal engine build. Anyone who’s familiar with California emissions knows that all legal engine swaps in CA must pass a rigorous inspection by a Bureau of Automotive Repair (BAR) state referee. This process requires the engine to be as new or newer than the vehicle, retain all engine and emission controls of that specific engine and pass a complete smog inspection (visual, functional and tailpipe). Furthermore, the engine used must be a USDM 50-state emissions engine. This means that JDM B16A and B18C engines cannot be used. Although some people claim to have passed a JDM B16A with the emissions and engine control equipment from a B16A3-equipped 94-95 Del Sol, we do not recommend going this route for the BAR process. At the end of the day, it’s up to the referee how strict they want to be and if they’ll let something like that slide or not. You don’t want to leave them any room or reason to fail you.

OBD What?

Since we’re forced to swap in a U.S.-spec engine, there are just a few different choices that we can choose from. Honda never offered an OBD0 B-series VTEC stateside, so making the move to an OBD1 or OBD2 setup is necessary. While an OBD2 setup requires the addition of the diagnostics port and other emissions-related equipment, making the switch to OBD1 is a relatively simple and straightforward process. For OBD0 vehicles, converting to OBD1 is simply the best way to go as it also offers much better tuning capabilities.

Since we’re forced to swap in a U.S.-spec engine, there are just a few different choices that we can choose from. Honda never offered an OBD0 B-series VTEC stateside, so making the move to an OBD1 or OBD2 setup is necessary. While an OBD2 setup requires the addition of the diagnostics port and other emissions-related equipment, making the switch to OBD1 is a relatively simple and straightforward process. For OBD0 vehicles, converting to OBD1 is simply the best way to go as it also offers much better tuning capabilities.

As far as OBD1 B-series VTEC engines, Honda/Acura only offered three choices: the 1992-1993 Acura Integra GS-R with the B17A1, 1994-1995 Honda Del Sol VTEC with the B16A3 and 1994-1995 Acura Integra with the B18C1. We were able to find both a B16A3 and a B17A1 locally. We opted to go with the B17A1 since the seller also included the cable-type transmission (YS1), OBD1 ECU (P61), factory intake manifold, header, distributor and other parts required for the swap.