As Uncle Ben once said, “with great power comes great responsibility.” There is no denying that properly-built 2JZ engines are capable of generating great power in a host of applications from daily-driven street cars to competition vehicles in drift, drag and land-speed applications. Being responsible with your parts selection and choosing the right machine shop and engine builder is a must if you want to reach your power and performance goals, while optimizing reliability and making intelligent investments. For over 30 years, the only choices available for the engine block for the 2JZ engine build were either a new or used 2JZ variant. Today, new 2JZ-GTE bare blocks are no longer available (but 2JZ-GTE short blocks are still available). While access to those blocks has faded away, Dart Machinery has launched its Iron Eagle 2JZ cast-iron block to not only fill this void, but to also support even higher performance levels while offering an overall value that will likely make it the “go-to” for many builders. To establish what’s best for you and your goals, we are going to compare the new Dart Iron Eagle 2JZ block with both used and new Toyota 2JZ blocks. Besides comparing the physical differences between these options, we will take everything a step further to consider the complete cost to have a ready-to-assembly 2JZ block.

Dart Machinery 2JZ Iron Eagle

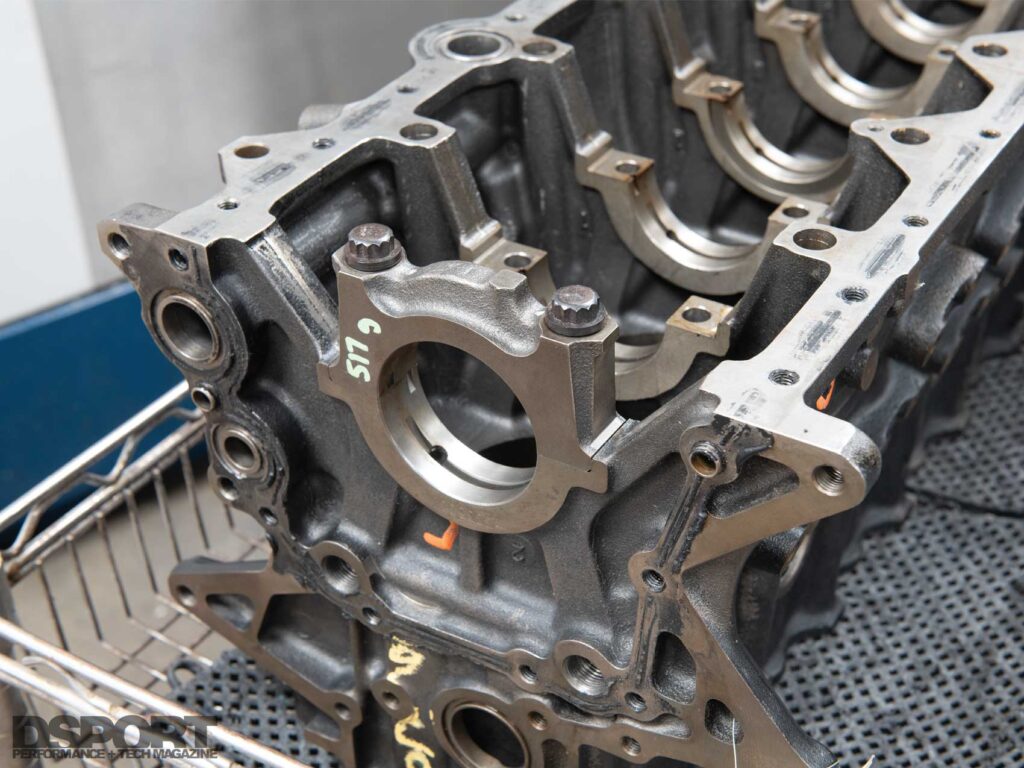

OEM 2JZ and the 650whp Limit

While it is possible to make over 650whp on a stock OEM 2JZ engine block, going beyond that number warrants a serious look at upgrading the main caps to a billet steel replacement. The factory 2-bolt main caps are cast iron and rather small in size. Each of the caps weigh in at just a little over 350 grams and each is secured to the block with a pair of M10 bolts that provide a total of roughly 20,000 pounds of clamping force. When a 2JZ engine produces over 550ft-lb of torque, these factory main caps begin to show their shortcomings. The main caps can begin to move around, and fretting can occur between the cap and block. Additionally, main bearing wear can be accelerated too.

Some may argue that the limit of the OEM 2JZ main caps is 800whp or even 1000whp. It’s really the torque output that is more of a factor than the horsepower. If you have a setup that limits torque to 500ft-lb, you could make 760whp at 8,000RPM or 810whp at 8,500RPM. But if you are making peak power at 6,200RPM, 500lb-ft of torque is going to get you just shy of 600whp. The bottom line is that it’s simply too easy to make more power on a turbocharged engine. If one is being “responsible”, the right decision is to follow is a path that eliminates this Achilles heel of the 2JZ.

DART 2JZ Block Review:

Goal: Compare the DART 2JZ engine block with a Toyota OEM 2JZ engine block. Compare the build cost of a Dart 2JZ vs. New OEM 2JZ vs. Used OEM 2JZ blocks.

Manufacturer Claims:

- Thicker cylinder walls

- Thicker deck surface (19mm/.750 thick)

- Thicker outer case (at least 40% thicker)

- Superior material used in the casting

- Available with oversized ½-inch head stud blind holes

- Improved water jacket design (scalloped) for improved cylinder cooling

- 4-bolt Steel Billet Main Caps with ARP 2000 Studs

- Includes screw-in aluminum core/freeze plugs

- Current Retail $4,635, Street price $4,500

Toyota OEM 2JZ main cap

OEM Used or New and Which Version?

For those enthusiasts that are in the market to purchase a 2JZ engine or block, there are a few different iterations of the block with various availability in new or used condition. The most desirable blocks will be the turbo blocks that have the provisions to run piston oil squirters. Piston squirters reduce the crown temperature of the piston, allowing for superior piston life and a better tune. As with purchasing any used performance part, there is always a chance that a used block may have irreparable damage. There can be cracks, severe corrosion or several other issues that may not show up until you go to assembly. Unless you know the history of a particular used engine block, always beware and have professional inspection where possible.

As previously mentioned, new 2JZ-GTE bare blocks are no longer available from Toyota. However, new 2JZ-GTE short blocks are still available. Selling off the pistons, crank and rods will get you into a new 2JZ-GTE bare block for about $2,500.

DART VS. OEM

Dart Iron Eagle 2JZ

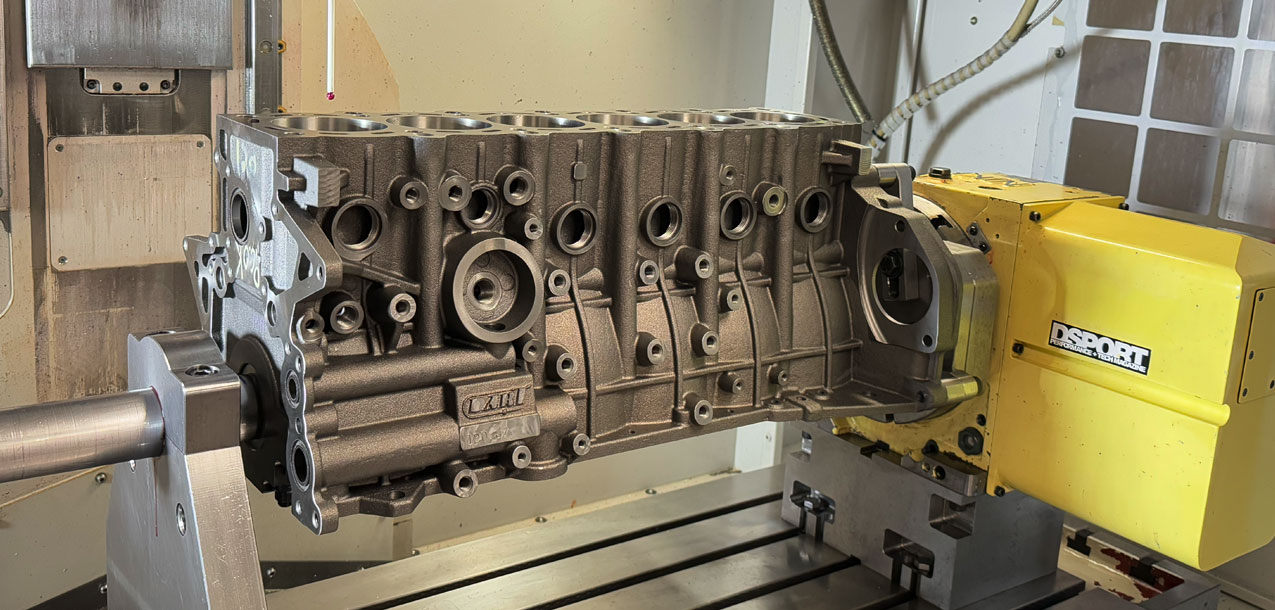

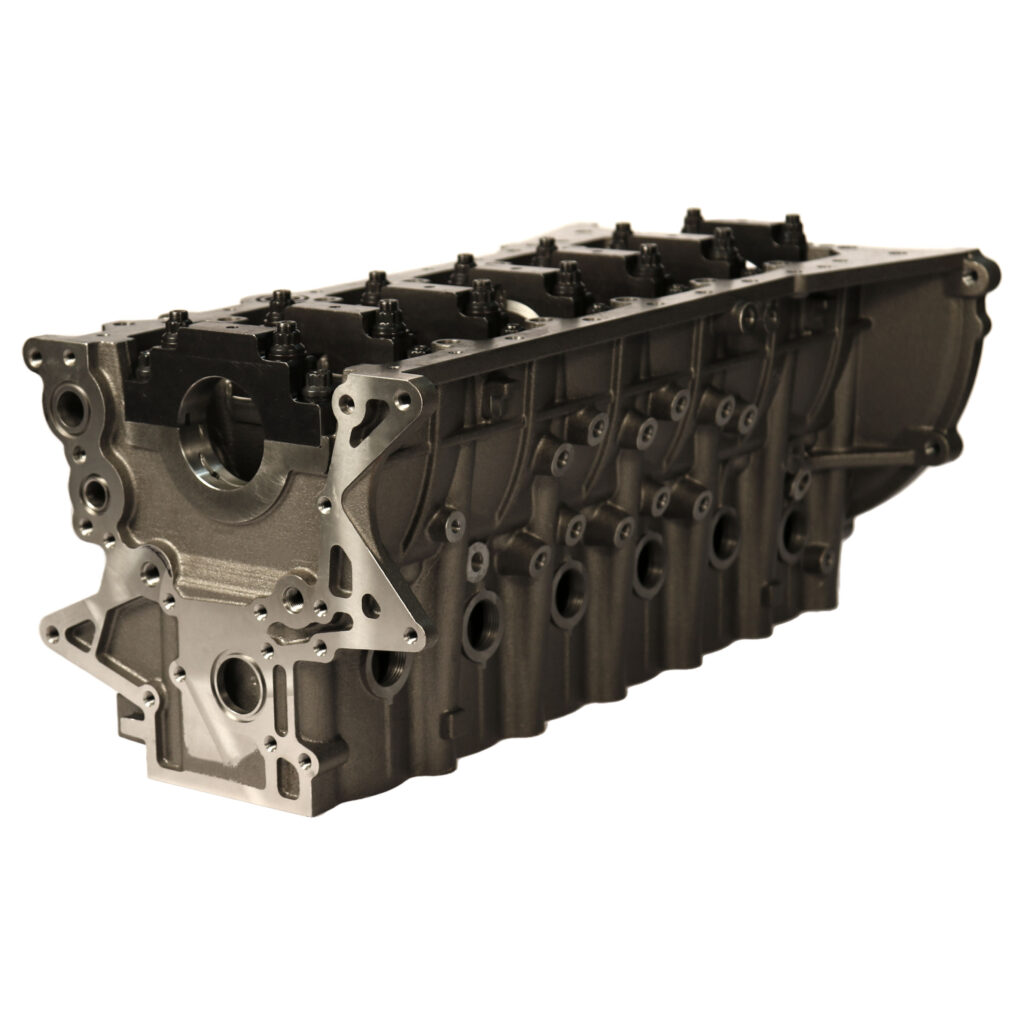

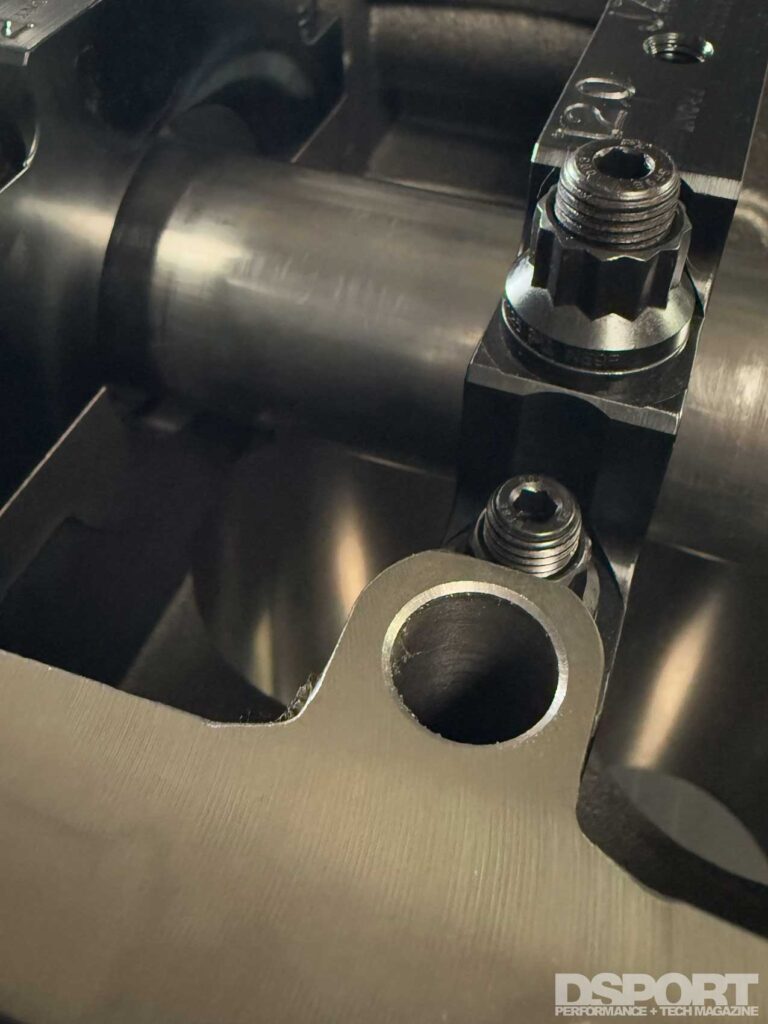

Dart’s Iron Eagle 2JZ was designed to offer superior performance and power handling over the OEM Toyota 2JZ blocks, while also reducing the amount of machining necessary. Since this was essentially a blank-sheet design that just needed to fit 2JZ cylinder head and accessories, major improvements could be engineered into the block. First and foremost, Dart addressed the Achilles heel of the 2JZ with a main cap and main stud arrangement that is superior to anything previously available. While the OEM block has two-bolt main bearing caps that are under 400 grams in mass, the Dart 2JZ 4-bolt caps are over 800 grams in mass. Where the OEM used a pair of M10 bolts to secure the cap with under 20K pounds of clamping force, the Dart caps use a pair of M10 studs and a pair of M12 studs manufactured by ARP to deliver over 50K pounds of clamping force. Even aftermarket 2-bolt billet steel caps secured with a pair of M12 studs only deliver 30K pounds of clamping force. This feature alone of the Dart 2JZ is worth $1,600-$1,800 when you consider the cost of aftermarket ARP main stud kit, aftermarket billet steel main caps and the machining cost to put those caps on an OEM 2JZ block. With the main weakness of the OEM 2JZ block addressed, engineers at Dart embarked upon addressing other areas to improve the block’s strength. Thicker deck surface and thicker cylinder walls were also incorporated into the design. The cylinder walls are thick enough that the non-siamesed walls will measure over 7mm in thickness even if the bore size is opened up to 88mm. The deck surface is over 19mm (3/4-inch thick) to improve cylinder head sealing at extreme cylinder pressures as well. You can see how these measures compare to the OEM 2JZ block in Chart A. In addition to addressing the most critical areas of the block, Dart also opted to make the overall structure of the block stronger too. Thicker walls (we measured about 2mm thicker) in the outer shell of the block further increase strength and limit deformation under high stresses and loads. Cylinder bore distortion is also limited under high-torque applications, as the motor mount locations do not distort as much when the engine is under extreme loads. Dart also engineered a different solution to address the cooling challenges of siamesed cylinders. Whereas the OEM Toyota block uses a conventional steam port approach on the deck surface of the engine block, you will not find these on the Dart block. Instead, Dart designed a scalloped water jacket design to eliminate the need. In addition to the design of the Dart 2JZ block, the manufacturing of the block also uses materials and processes that deliver a superior product. The cleanliness of the casting is far superior, while the material itself is also higher strength. Other improvements include aluminum screw-in style freeze plugs with o-ring seals.

Dart 2JZ Iron Eagle Options

Currently, there is only one option to consider when purchasing a Dart 2JZ block: head stud size. The Dart 2JZ is offered with holes tapped for standard OEM 11mm-sized head bolts/studs or for larger ½-inch head studs. For most builds, the 11mm-sized is the way to go. With a good head gasket, properly prepped deck and cylinder head and a set of ARP CA625+ head studs, the 11mm setup can handle well over 1,200whp. Best of all, there is no need to modify the head gasket or drill out the cylinder head to fit ½-inch studs. While we ordered an 11mm setup for our build, it was backordered, so we took delivery of a ½-inch version instead. The ½-inch studs in ARP2000 or ARP8740 have less clamping strength than the 11mm ARP studs in CA625+ alloy. If you want to exceed the clamping strength of the 11mm ARP studs in CA625+, you will have to order the ½-inch head studs in CA625+ too.

The Tale of the Tape

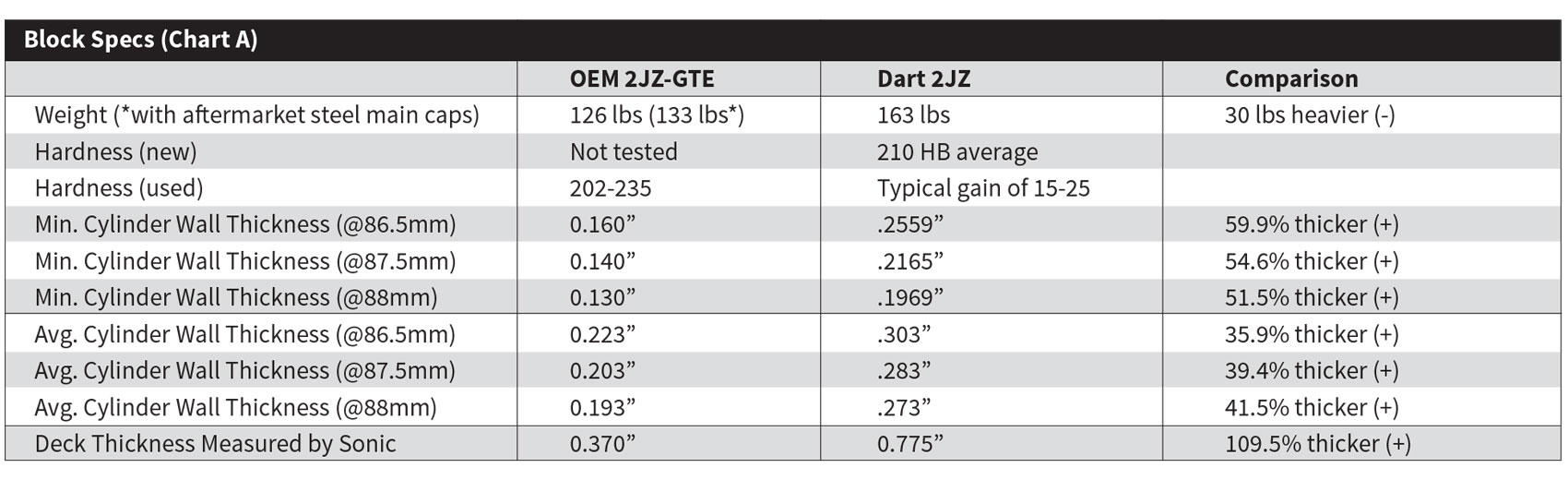

We decided to measure the block’s weight, hardness and wall thicknesses in our testing. Since the Dart 2JZ block is thicker in design, it weighs 30 pounds more than an OEM Toyota block that has been fitted with aftermarket steel main caps. That’s about a 23% increase in mass. When running extreme cylinder pressures and high horsepower, this additional mass can save your ass.

In our hardness testing, we tested the Dart 2JZ block against a number of used 2JZ OEM blocks. Our average hardness for the new Dart 2JZ block was 210HB, while the used block we tested was 202HB. Some of the older, higher mileage 2JZ used blocks that we had laying around tested between 195 and 220HB. However, you must consider that cast iron ages and hardens over time. This means that the Dart block will only get harder with time and use.

With our hardness testing of 100s of cast-iron blocks over the past 10 years, we have made some observations. First, no two blocks are ever the same (even when new). Some will end up harder than others even when both are new. Second, the hardness of the block isn’t the same in all locations. This means that a comparison of one block to another should be conducted at the same location on each block to compare results. Third, the same blocks will get harder with age and use. We have new engines that were put together with blocks that measured 195HB, only to see this number rise to 205 or 210 when refreshed a few years later.

More material that’s also harder helps to increase strength, but increasing the thickness is the other reason for the additional strength in the Dart 2JZ block. In the areas of the block where we could measure the thickness with a micrometer, we would find the outer shell of the block to be about 7mm in thickness, where the OEM block was only 5mm. That’s a 40-percent increase in thickness. For the blind areas where a measuring tool can touch both sides, we relied upon sonic testing to determine wall thickness.

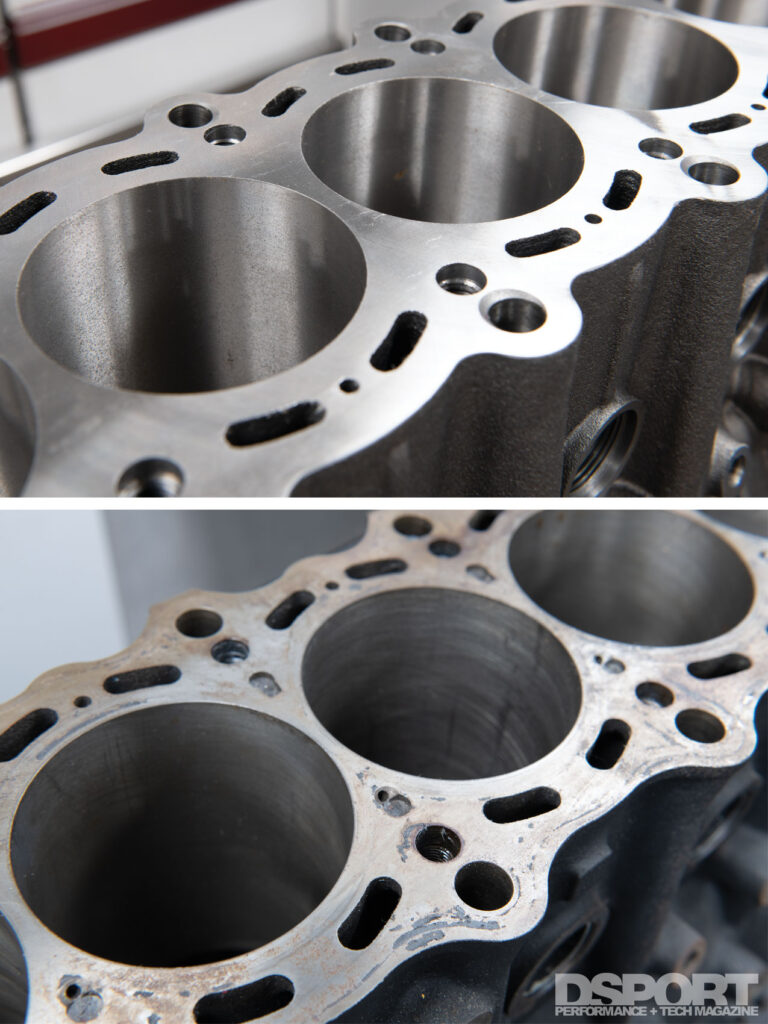

Dart claims a deck surface thickness of over 19mm. We measured it to be about 19.7mm or 0.775” thick with our sonic tester. On the OEM 2JZ block we measured 0.370” or a little over 9mm thick. Hence, the Dart block’s deck surface is more than twice as thick. This additional thickness reduces the distortion created from high clamping loads. Those improvements lead to superior combustion chamber and head gasket sealing. In addition, the increased deck thickness also means that the top of the cylinder that sees the higher cylinder pressures is also the strongest part of the cylinder for nearly twice the distance as the OEM cylinder.

As for the cylinder wall thickness, the siamesed portion between cylinders is exactly the same as the OEM block, as this is just a function of the 2JZ’s 93mm bore spacing, siamesed cylinders, and the final bore size of the cylinder. At 86mm, the thickness is 0.2756”. At 86.5mm, 87.0mm, 87.5mm and 88.0mm final bore size, the thickness at the siamesed section is 0.2559”, 0.2362”, 0.2165” and 0.1969”, respectively. When testing the thickness of the non-siamesed walls, we measured the thickness on the Dart2JZ to be about 0.020~0.055” thicker than the siamesed section. This means at no matter the final bore size, the siamesed portion is always the thinnest section.

When testing the cylinder wall thickness on the OEM Toyota 2JZ block, there were always thinner sections than the siamesed section. When the siamesed section was between 0.215 and 0.220” on an 87.5mm bored block, the size opposite on the number one cylinder was measuring only 0.148”, about 0.070” thinner. The thinnest spot we found in cylinder one had a wall thickness of just 0.140”. While that wall thickness may be OK for a naturally aspirated or lightly boosted engine, you will want thicker if you are going to be running 45-100psi of boost pressure. That’s why going beyond an 86.5mm bore size with an OEM Toyota 2JZ block isn’t typically done.

Block thickness

Saving Time and Money?

One of the biggest advantages with starting your 2JZ engine build with a Dart Iron Eagle 2JZ is the amount of time that can be saved. Since the Dart block is delivered needing only a final honing, some minor deburring and thorough washing, it can be taken out of the box in the morning, final honed, deburred, cleaned and be ready for assembly at the end of the day. In contrast, a new OEM Toyota 2JZ block is going to need to be prepped for installation of aftermarket billet main caps and undergo a line boring operation (possibly a line honing operation too depending on the machine shop’s capabilities). Since the line boring operation may slightly offset the crank centerline, the proper follow-up is cylinder boring on a 4-axis engine machining center to ensure the cylinders are perpendicular to the crank’s centerline. The OEM oil galley balls must also be removed, then drilled and tapped for NPT plugs. If your machine shop has no other jobs to complete and really likes you, this is an additional 3 to 4 days of rush work. More than likely, this is an additional 3 to 4 weeks or more as line boring is one of the operations that few machine shops enjoy. Of all the machine shop operations that your local machine shop is likely to screw up, line boring is at the top of the list. So besides the wait, there is also a chance that these additional machining processes will not be executed at the highest level of precision. The cost for aftermarket ARP main stud kit, aftermarket steel billet main caps and the machining for the installation of the caps will most likely run about $1600-$2,000. If you add that to the cost of a new 2JZ block being $2,500, you can quickly be at the same price as a Dart 2JZ block without getting any of the benefits that the Dart 2JZ block offers.

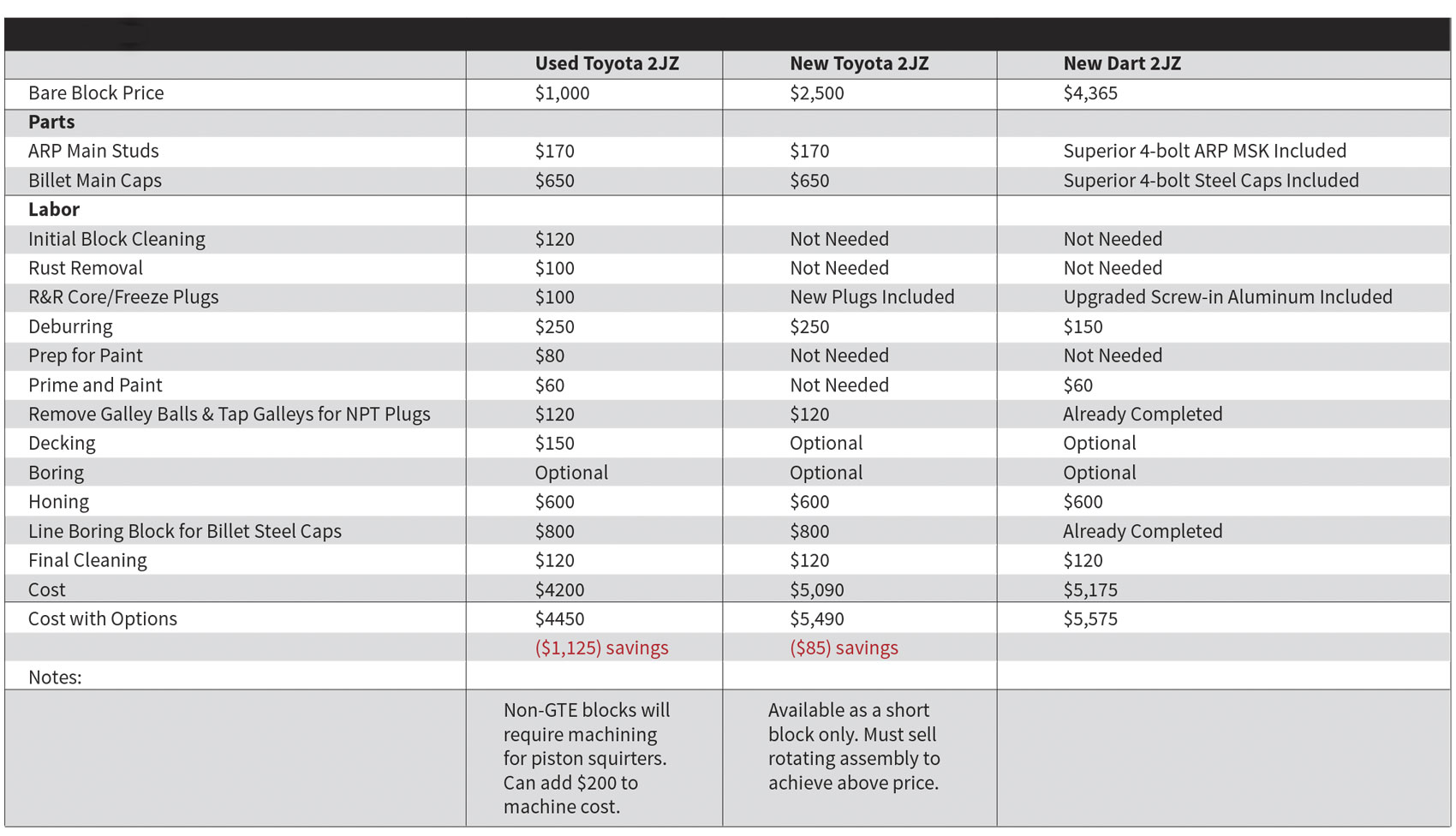

Dollars and Sense

In looking at the typical cost to go from a used 2JZ block, a new OEM 2JZ block and a Dart 2JZ block from delivery to ready to assemble, the costs are very comparable. The cheapest route with a used 2JZ block will run about $4,200-$4,450 if $1,000 is spent on the used bare block. Of course, there is the highest risk of additional costs or wasted money if problems are found with the used block and machining operations are performed on a unrepairable block. Spending about $900 more removes a lot of the unknowns and risks if a new OEM 2JZ is the basis for the build. However, don’t be surprised to have the machine shop take 3 to 4 weeks (or 3 to 4 months in some areas) to get this job completed. For less than $100 more than the new OEM block or $1,125 more than a build of a used 2JZ block, a Dart Iron Eagle 2JZ block can be ready to assemble after spending $5,175-$5,575 in total. Best of all, the required machining shouldn’t take more than a week even at a busy machine shop to complete and can be done in a day in a rush situation.

Price chart

The Bottom Line

Anyone interested in the half-dozen used 2JZ cores that we have give us a call. We hate tying up our CNC machine for a day or two to complete a line boring operation on an OEM 2JZ engine. That’s probably a major reason why we build 10 Nissan RBs for every 2JZ. From a machine shop and engine assembler viewpoint, the Dart Iron Eagle 2JZ is the obvious and superior choice over a used or new OEM Toyota 2JZ engine block. Versus a new OEM block, you spend under $100 more for a block that is superior in just about every measurable category (except it is 30 pounds heavier). From an enthusiast standpoint, we come to the same conclusion. We went into this editorial thinking we’d have to figure out the limited customer base for the Dart Iron Eagle 2JZ engine block. After our testing we came out thinking the opposite. It’s easier to identify the select few where the Dart 2JZ is not the best choice. So here is the simple rule: if you are planning to build a 2JZ that will produce in excess of 600whp, get the Dart Iron Eagle 2JZ block. If you are OK being asked what’s wrong with your 2JZ-powered vehicle when you tell them it makes 550 horsepower or less, stick with the OEM block with its OEM main caps and call it a day. After all, with little power comes little responsibility.