The 1980s were challenging times for performance. OEMs were experimenting with the transition to fuel injection from carburetors, as increased emission regulations resulted in systems that choked off performance in a big way. In fact, the 5.7-liter in the 1984 Corvette only produced 205bhp at the flywheel. With its 3,200-pound curb weight, the 1984 Corvette delivered only 6.2 horsepower per 100 pounds of vehicle weight. The Corolla GT-S during the ‘80s offered power output as high as 123 horsepower (JDM edition) with a curb weight as low as 2,200 pounds. This translated to a 5.6 horsepower-per-100-pounds power-to-weight ratio which gave it some decent performance for its time. Considering that the 4AGE engine in the AE86 Corolla had a factory redline up to 7,700 RPM, the Corolla GT-S was arguably more fun to drive than the early C4 Corvettes while also being a ton more reliable. While many fans were impressed during the ‘80s by what the Corolla GT-S could do against other platforms of its era, its performance was soon eclipsed by what Honda would deliver in its series of all-aluminum 1.6-liter twin-cam engines (ZC and B-series). Since the performance output of the factory 4AGE engines we received in the States never lived up to the immense hype from its fanbase, it earned a spot on the DSPORT Magazine Top 5 Worst Engines of all Time (#2 after the Mitsubishi G54B). After pissing off the 4AGE fanbase for the last 10 years, it seemed only right to build up a 4AGE that would impress even the most hardcore haters.

By Michael Ferrara // Photos by Joe Singleton

DSPORT Issue #225

The original 4AGE engine received some top-end upgrades but still only managed 110whp. Adding the 80-horsepower direct-port nitrous oxide shot was a must to keep up with competition on the straightaways.

Hating the Hype

When I purchased my 1985 Toyota MR-2 back in 1996, I had heard plenty of good hype about its 4AGE engine. In fact, two of my good friends (Aric Shen and Shawn Carlson) also purchased 1st generation MR-2s within a few weeks of my purchase. We were all hyped on what this “impressive” 1.6-liter would be able to do in a lightweight, mid-engine platform. After seeing very little improvements with the basic bolt-ons (intake, exhaust and header) and limited success with a turbocharger kit, we all abandoned the projects within a year. The 4AGE engine just couldn’t shine with basic bolt-ons and the aftermarket technology available in the mid ‘90s.

This used 4AGE block that once struggled to put out just over 110hp will be getting the right parts, machine work and assembly to make over 200 horsepower at the wheels.

Second Chance

Alan Viado has had quite a different experience with 4AGE-powered vehicles. While living in Hawaii back in 1996, Alan’s 11-second turbo Del Sol blew the engine. A friend lent him his Corolla GT-S and he fell in love with the platform. This was Alan’s first taste of a RWD drive and learning to navigate through Oahu’s makeshift togue drift at Tantalus got Alan hooked. Unable to find a clean GT-S of his own, Alan tried to satisfy his performance fix with a 2000 WRX. The WRX (turbo power with A/C) eventually got Alan to participate in track days, but he still longed to get a GT-S in the future. Around 2015, Alan got a GT-S coupe with an S2K engine swap. The car was clean and the swap was done right, but it just didn’t behave like the GT-S hatch he remembered. When the chance came a couple months later to buy another friend’s 1987 Corolla GT-S hatchback, Alan couldn’t say no. He sold the S2K-swapped coupe and had the GT-S on the next container ship leaving Hawaii. The interior and body of the 1987 Corolla GT-S were pristine, and it even sported one of the rarer color options. After going through the suspension and drivetrain, Alan decided to upgrade the top-end of the engine with some ITBs, aftermarket ECU, cams and a performance valve job. While the intake was off the vehicle, Alan’s friend Gary Castillo talked Alan into putting on an 80-horsepower direct-port nitrous-oxide system. With the top-end of the engine refreshed, the 4AGE managed to put down 110whp (130bhp). Needless to say, that figure meant that Alan would be using the 80-horsepower shot on every straightaway the GT-S encountered on the racetrack.

When Alan inquired about making the 4AGE in his GT-S better, I likely suggested the first upgrade should be a FOR SALE sign. Then I remembered about the progress we’ve made in developing the number-one worst engine on the DSPORT Five Worst Engine list for our Project Starion and thought it was only fair to take a deeper look at the potential of the 4AGE using today’s technology and the capabilities of Club DSPORT. While the 4AGE may not have VTEC or a great flowing cylinder head out of the box, it is an extremely durable engine that was the basis of the Toyota Atlantic IndyCar series for a number of years. In full-race trim, the 16V Toyota Atlantic engines produced anywhere between 210 and 242 horsepower depending on the builder and the dyno used. If we could end up with a 4AGE build that could deliver 200whp (235bhp on flywheel) on the chassis dyno while also being able to push-to-pass the competition with an 80-to-100 horsepower direct-port nitrous oxide blast available on demand, I think even a hardcore hater like myself could find love for this 4AGE project.

No Boost, No Problem

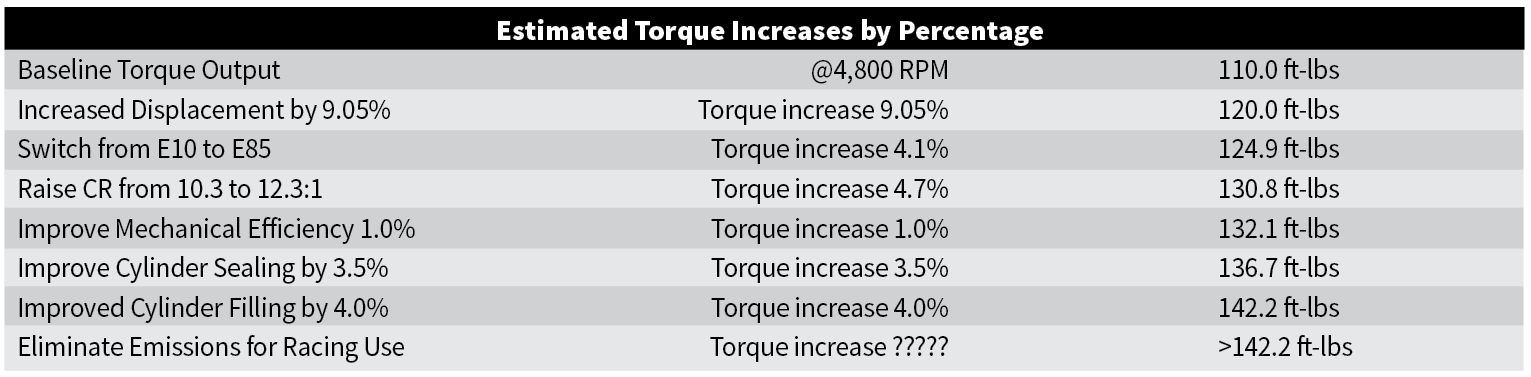

Naturally-Aspirated, Normally-Aspirated or All-Motor. Whatever you call it, building an engine without the addition of forced induction can often be more of a challenge than a boosted engine. With any engine, the power and torque output are simply a function of how much fuel can be burned and how much energy can be realized from the combustion of this fuel. Burning the maximum amount of fuel requires getting the maximum amount of air into the engine. On forced induction applications, the compressor section of the supercharger or turbocharger can pack the cylinders with air at elevated pressures and densities (aftercooled), so that more pounds or grams of air are present to burn more pounds or cc of fuel. With an “All-Motor” engine, the engine’s displacement, rotational speed (RPM), and volumetric efficiency (referred to as VE) determine just how many pounds of air it can ingest (and the resulting number of pounds of fuel it can combust). The engine’s compression ratio and its mechanical design determine the percentage of combustion energy that gets turned into horsepower at the crankshaft. Some of this energy is used to overcome friction while some of this combustion energy is simply turned into heat instead of horsepower. This heat gets rejected into the cooling system and exhaust.

We worked with JE Pistons to design the ultimate piston for our combination. We’ll tell you more about the pistons and rings next month, but we’ve included just about every feature possible for maximum performance and reliability. The new pistons will bump compression to 12.3:1. This will be a nice static compression ratio for the E85 fuel.

Bigger, Stronger, Faster

With this 4AGE build we decided to take advantage of the fact that Brian Crower offers a stroker crankshaft and connecting rod solution. The additional 6mm of stroke (going from 77mm to 83mm) adds 7.8-percent more displacement by itself. An 81.47mm enlarged cylinder bore helps to take the total displacement gain to 9.05%, going from 1,587.1cc to 1,730.7cc. That increase in displacement directly translates into a like increase in torque output, all other factors remaining equal. In addition to making the engine bigger, we wanted it to be stronger.

Total Seal made us a custom ring set optimized for the high RPM and nitrous-oxide abuse this engine will endure. A gas-ported top ring was a priority for superior sealing. We used the specs from Total Seal to have the ring grooves cut into the piston.

To add additional strength to the engine block, we will be installing a set of Billet Speedworks steel main caps and ARP main studs in place before performing a vertical line boring operation in our CNC. Like the 2JZ-GTE, the main cap on the 4AGE is a little on the light side. While it may prove entirely adequate at factory power and RPM levels, going 9,000RPM and beyond with the added cylinder pressure from a 100-horsepower shot of nitrous oxide may prove to be too much. However, with the billet steel main caps and a set of ARP main bolts in place, there will be nothing to fear. The caps will keep the BC Brian Crower 83mm 4340-alloy billet steel stroker crankshaft in place. The crankshaft will be spun up by a quartet of custom JE Pistons fitted on 4340 billet steel BC Brian Crower rods sporting ARP CA625+ alloy fasteners. The 2618-alloy JE Pistons custom pistons were built around a custom ring set from Total Seal featuring a gas-ported top ring, Napier second ring and three-piece oil control ring package. Total Seal provided the groove specifications for the pistons to optimize the ring seal. In addition to the precision cut ring grooves, the custom JE Pistons feature a 2.0-point increase in static compression ratio (from 10.3:1 OEM to 12.3:1), wider and deeper valve pockets for oversized valves and higher-lift cams, electroless nickel plating, anti-scuff skirt coating, offset pin location, upgraded pins and asymmetric skirt design. The end result is a piston that is lighter than the factory piston yet far superior in sealing and power handling.

To add additional strength to the engine block, we will be installing a set of Billet Speedworks steel main caps and ARP main studs in place before performing a vertical line boring operation in our CNC. Like the 2JZ-GTE, the main cap on the 4AGE is a little on the light side. While it may prove entirely adequate at factory power and RPM levels, going 9,000RPM and beyond with the added cylinder pressure from a 100-horsepower shot of nitrous oxide may prove to be too much. However, with the billet steel main caps and a set of ARP main bolts in place, there will be nothing to fear. The caps will keep the BC Brian Crower 83mm 4340-alloy billet steel stroker crankshaft in place. The crankshaft will be spun up by a quartet of custom JE Pistons fitted on 4340 billet steel BC Brian Crower rods sporting ARP CA625+ alloy fasteners. The 2618-alloy JE Pistons custom pistons were built around a custom ring set from Total Seal featuring a gas-ported top ring, Napier second ring and three-piece oil control ring package. Total Seal provided the groove specifications for the pistons to optimize the ring seal. In addition to the precision cut ring grooves, the custom JE Pistons feature a 2.0-point increase in static compression ratio (from 10.3:1 OEM to 12.3:1), wider and deeper valve pockets for oversized valves and higher-lift cams, electroless nickel plating, anti-scuff skirt coating, offset pin location, upgraded pins and asymmetric skirt design. The end result is a piston that is lighter than the factory piston yet far superior in sealing and power handling.

BC Brian Crower supplied the 4340 billet steel 83mm stroker crankshaft and 4340 H-beam rods fitted with ARP Custom Age 625+ rod bolts. These upgraded bolts are designed for high RPM duty.

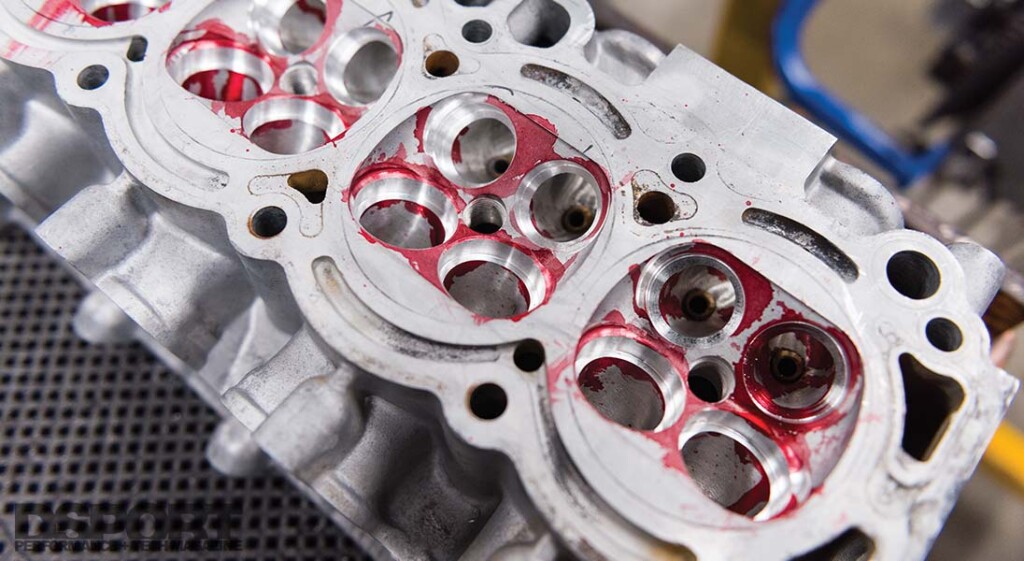

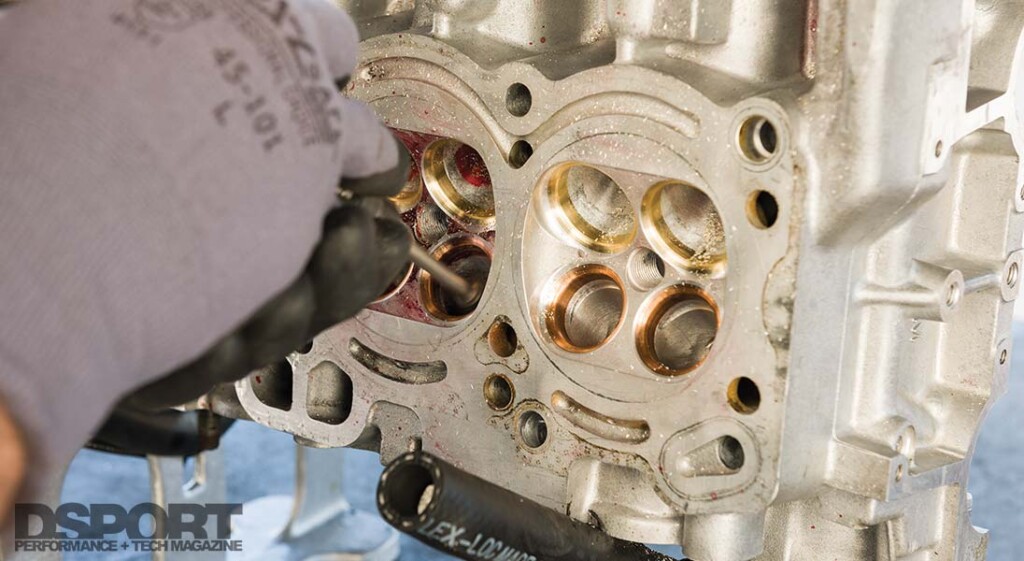

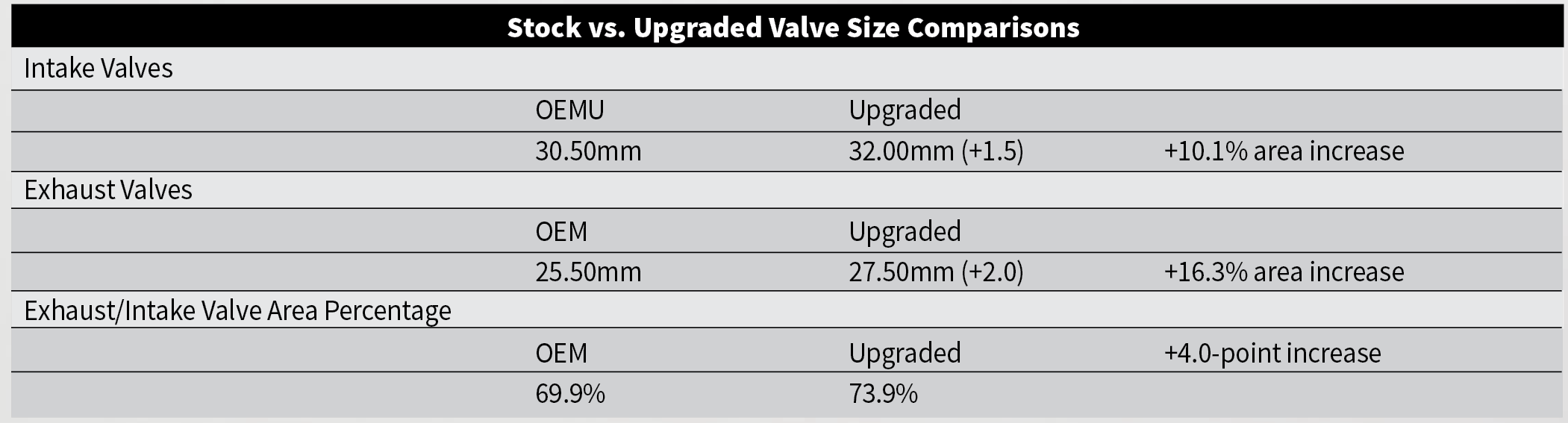

As for being faster, the engine is getting the proper machine work and cylinder head work to spin faster and fill cylinders better than ever before. Supertech has provided the valvetrain solution to be able to increase the valve sizes to Formula Atlantic specs. This massive increase in valve size requires larger valve seats to be installed. While we could have opted for a budget seat, the fact that nitrous oxide and occasional visits to 10,000 RPM will be in the future prompted us to seek out the best possible seats for the application. To this end, CHE Precision made us the custom intake and exhaust seats that used bronze alloys of varying copper content for optimized use in the intake and exhaust positions.

After the new guides were installed, we machined out the old valve seats and prepped them for the new oversized seats. Rough porting was done before the new seats were installed and final porting was completed after the new seats and valve job were completed.

Due to the massive increase in valve size over the OEM valves, replacement of the seats was needed. We upgraded to the best material available to survive the torture of high RPM and nitrous oxide.

After the installation of the seats and the valve job, additional care must be taken as to not damage the seats while blending the transition from the seat to the bowl area.

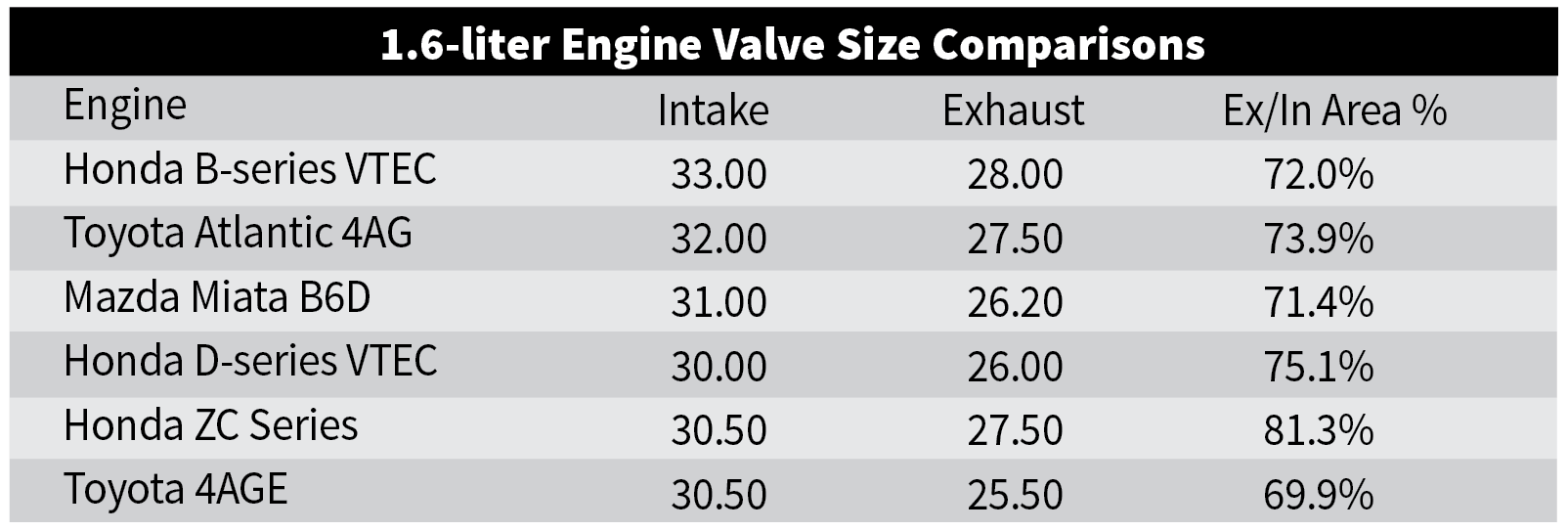

One of the reasons that Honda’s B16A was able to deliver more than 100 horsepower per liter in OEM form was the fact that it used large 33mm intake and 28mm exhaust valves in its cylinder head. Honda used what it learned from its ZC series cylinder head to use a much larger intake valve for a valve area balance of 72.0% between the exhaust and intake. Toyota’s 4AGE was its first 4-valve per cylinder engine and they went a bit too conservative on valve sizes. For racing trim in the Toyota Atlantic series, the valve sizes were dramatically increased and more bias for exhaust valve area was made. We opted to use a Supertech valvetrain with the Toyota Atlantic valve sizes for our project.

An engine’s torque output is directly tied into its displacement and peak cylinder pressures. An increase in displacement, change in fuel to E85, bump in compression ratio and the right parts selection and machine work to increase the cylinder sealing and cylinder filling should take torque output from 110 ft-lbs to the 135-to-145 ft-lbs range.

BIG PORT vs. SMALL PORT 4AGE

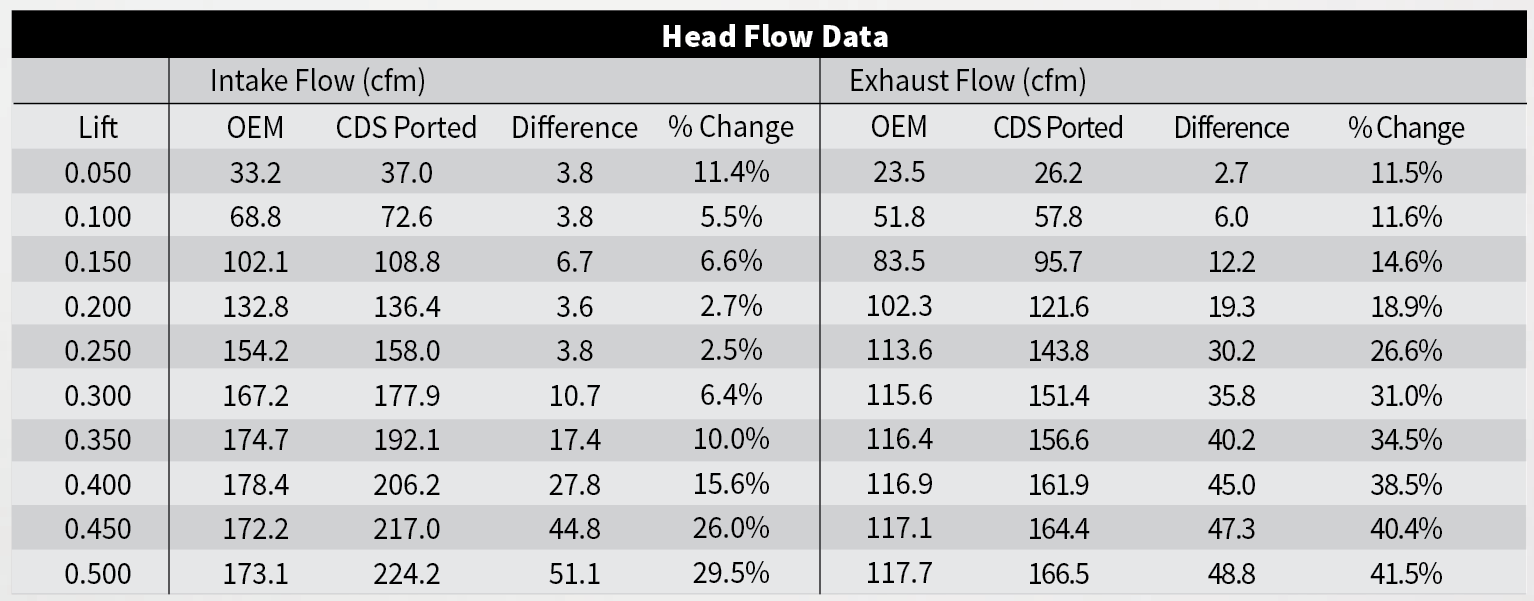

The Toyota 4AGE engine is most commonly found with a “big-port” cylinder head and a T-VIS (Toyota Variable Induction System) intake manifold. All of the RWD and most of the FWD applications have the big-port cylinder head. The massive ports (big port) required the use of a T-VIS (to improve low engine speed torque output and cylinder filling. This system featured an intake manifold with two runners per cylinder. One of the runners for each cylinder was fitted with a butterfly valve that would remain closed until higher engine speeds (above 4,200 RPM). Before the T-VIS valves were open, the single runner would induce swirl into the intake port. While this may have been beneficial to the engine had it been carbureted, the swirl in the intake port wasn’t needed to further atomize the injected fuel and the amount of swirl it induced into the combustion chamber (which would have been beneficial) was minimal. Instead, the swirl simply wasted energy in the flow that could have helped to fill the cylinders. With the T-VIS open at higher engine speeds, the system reduced the swirl component, but the butterfly and shaft did induce some unwanted turbulence into the intake flow. Ultimately, this band-aid wasn’t the ideal fix and Toyota later went to a smaller port cylinder head better balanced for the 4AGE’s relatively small valves. While the big-port engines were rated at 112-to-115hp, the small-port was rated 7.0% higher at 123 horsepower. While we could have opted to start with the big port head and add material to get an optimized port, we thought it would be easier to take the smaller port and optimize its shape and size for the larger valves. The small-port 4AGE engines were fitted in 1988-93 AE92 Corolla and the 1990-1992 Geo Prizm GSi. These engines can easily be identified by their lack of a T-VIS intake manifold.

The Toyota 4AGE engine is most commonly found with a “big-port” cylinder head and a T-VIS (Toyota Variable Induction System) intake manifold. All of the RWD and most of the FWD applications have the big-port cylinder head. The massive ports (big port) required the use of a T-VIS (to improve low engine speed torque output and cylinder filling. This system featured an intake manifold with two runners per cylinder. One of the runners for each cylinder was fitted with a butterfly valve that would remain closed until higher engine speeds (above 4,200 RPM). Before the T-VIS valves were open, the single runner would induce swirl into the intake port. While this may have been beneficial to the engine had it been carbureted, the swirl in the intake port wasn’t needed to further atomize the injected fuel and the amount of swirl it induced into the combustion chamber (which would have been beneficial) was minimal. Instead, the swirl simply wasted energy in the flow that could have helped to fill the cylinders. With the T-VIS open at higher engine speeds, the system reduced the swirl component, but the butterfly and shaft did induce some unwanted turbulence into the intake flow. Ultimately, this band-aid wasn’t the ideal fix and Toyota later went to a smaller port cylinder head better balanced for the 4AGE’s relatively small valves. While the big-port engines were rated at 112-to-115hp, the small-port was rated 7.0% higher at 123 horsepower. While we could have opted to start with the big port head and add material to get an optimized port, we thought it would be easier to take the smaller port and optimize its shape and size for the larger valves. The small-port 4AGE engines were fitted in 1988-93 AE92 Corolla and the 1990-1992 Geo Prizm GSi. These engines can easily be identified by their lack of a T-VIS intake manifold.

With the reshaping of the port, the goal was to get the maximum flow gains with the minimal increase in cross-sectional area. This leads to a high-velocity port that fills the cylinders for maximum power. Making the ports big just slows the airflow.

We couldn’t have been more pleased with the results from Club DSPORT’s work on the 4AGE small-port cylinder head. Flow improvements were realized from low to high valve lifts showing that the ports work well. The cams we selected will have a peak lift of 0.424” on the intake and 0.423” on the exhaust. In that range, the head will be seeing peak flow of around 210cfm on the intake and 163cfm on the exhaust. With the OEM cams and ports, peak intake flow was in the 160cfm range with exhaust flow measuring 114cfm.

Bigger valves can lead to better performance if, and only if, the ports are optimized for the larger valves. The larger valves featured a 10-percent and 16-percent gain in area for the intake and exhaust respectively. Just throwing these into the stock ports may have resulted in a reduction in flow. When you ovesize the valves be sure that the proper attention is given to reshaping the ports properly.

The Missing Pieces

At press time, we are currently waiting for the Billet Speedworks steel main cap set and TOMEI POWERED USA camshafts to arrive. While we anxiously await the arrival of the parts, we will be producing the custom tooling required for the 4AGE engine. This will include locator rings for the 4-axis CNC block machining center, torque plate for honing of the cylinders and a “hot plate” for the cylinder head to torque up the cylinder head during valve jobs. Once we receive the pieces we should have the block processed within a week and can move on to assembly. While we may start with the intake manifold, throttle bodies and exhaust header that we currently have in place, chances are we will need to optimize these to maximize cylinder filling to reach our performance goals. Stay tuned.