Nothing can put the brakes on a project quicker than a FROZEN nut or bolt. Aside from being a massive frustration, seized hardware can lead you to demolish perfectly good tools or bust a knuckle or two. While there isn’t one perfect tool that can remove all rusted fasteners, there are a few procedures that have proven effective. From torches, bolt extractors and impact wrenches to penetrating oil and homemade alternatives, here’s a quick look at some knuckle-saving techniques.

Text and Photos by Robert Choo

DSPORT Issue #88

Public Enemy #1

Make no mistake; rust and other types of metal oxidation are your enemy. Unfortunately, the underside of a car is a perfect environment to breed rust. There are ferrous materials like steel and iron, moisture and oxygen. That’s all of the ingredients needed for chemical oxidation or “rust” to occur. When electrolytes, like those found in road salts, are added to the mix, the rusting process can be significantly accelerated.

Now that you know how it happens, let’s focus on getting that problem hardware off of your car. There are four popular methods to loosen a stuck bolt: the use of a penetrating lubricant, a paraffin wax, rust-eating solutions (like Diet Coke) and heat.

All Lubed Up

The liberal application of penetrating lubricant is by far the most common way to persuade a seized fastener into turning loose. It’s likely that you’re familiar with products like WD-40, PB Blaster Penetrating Catalyst, Liquid Wrench or Royal Purple Max Film. Talk to enough mechanics and everybody seems to have a favorite. When applied to a rusted fastener, these lubricants work their way into the tiny space between the threads of the nut and bolt, break down the chemical oxidation along the way. Once enough of the oxidation softens, the bolt should be easier to turn. Simply spray the problem area and allow five minutes for the penetrant to work. By tapping lightly on the nut or bolt you can help to break some of the areas bonded by the rust. If the bolt still doesn’t turn, reapply again and wait 10 more minutes. If there’s no luck, you can try a third application and wait overnight. If that doesn’t work, it’s time for plan B.

Wax On, Wax Off

OK Daniel-san, if you don’t have any penetrating lubricant on hand or you want to try another technique, the wax method may be your savior. Long before Norm Larsen figured out the formula for WD-40, mechanics were using wax to do their dirty work. All you need is some paraffin wax (candle wax) and a source of focused heat. A propane torch or a heat gun should be used to gently heat the fastener. In this case, you don’t have to get it too hot, just warm enough to melt the wax. Once the metal is warm enough, touch the candle to the fastener around the edges and allow the wax to melt. The heat will pull the wax into the gaps between the bolt and nut threads and allow for easier turning. Remember that the wax will tend to flow to the heat source, so heat the bottom threads the most. If this technique fails, it’s time for plan C or D.

OK Daniel-san, if you don’t have any penetrating lubricant on hand or you want to try another technique, the wax method may be your savior. Long before Norm Larsen figured out the formula for WD-40, mechanics were using wax to do their dirty work. All you need is some paraffin wax (candle wax) and a source of focused heat. A propane torch or a heat gun should be used to gently heat the fastener. In this case, you don’t have to get it too hot, just warm enough to melt the wax. Once the metal is warm enough, touch the candle to the fastener around the edges and allow the wax to melt. The heat will pull the wax into the gaps between the bolt and nut threads and allow for easier turning. Remember that the wax will tend to flow to the heat source, so heat the bottom threads the most. If this technique fails, it’s time for plan C or D.

The MacGyver Tactics

If you’re feeling particularly MacGyver-esque, there’s always Diet Coke or a rust-fighting solution like Evapo-rust. Bubbly soft drinks like Diet Coke and regular Coca-Cola contain phosphoric acid, a substance known to do a number on rust. Diet Coke doesn’t contain the sugars so it’s generally easier to clean up and doesn’t attract ants. Pour the Diet Coke or Evaporust around the bolt and let it soak in. You may need to soak a rag in the solution to keep it in the right area. You can also use some crumpled aluminum foil to wipe away the dissolved rust. This method takes the longest (you’ll generally need to wait overnight), so consider this a last ditch effort.

If you’re feeling particularly MacGyver-esque, there’s always Diet Coke or a rust-fighting solution like Evapo-rust. Bubbly soft drinks like Diet Coke and regular Coca-Cola contain phosphoric acid, a substance known to do a number on rust. Diet Coke doesn’t contain the sugars so it’s generally easier to clean up and doesn’t attract ants. Pour the Diet Coke or Evaporust around the bolt and let it soak in. You may need to soak a rag in the solution to keep it in the right area. You can also use some crumpled aluminum foil to wipe away the dissolved rust. This method takes the longest (you’ll generally need to wait overnight), so consider this a last ditch effort.

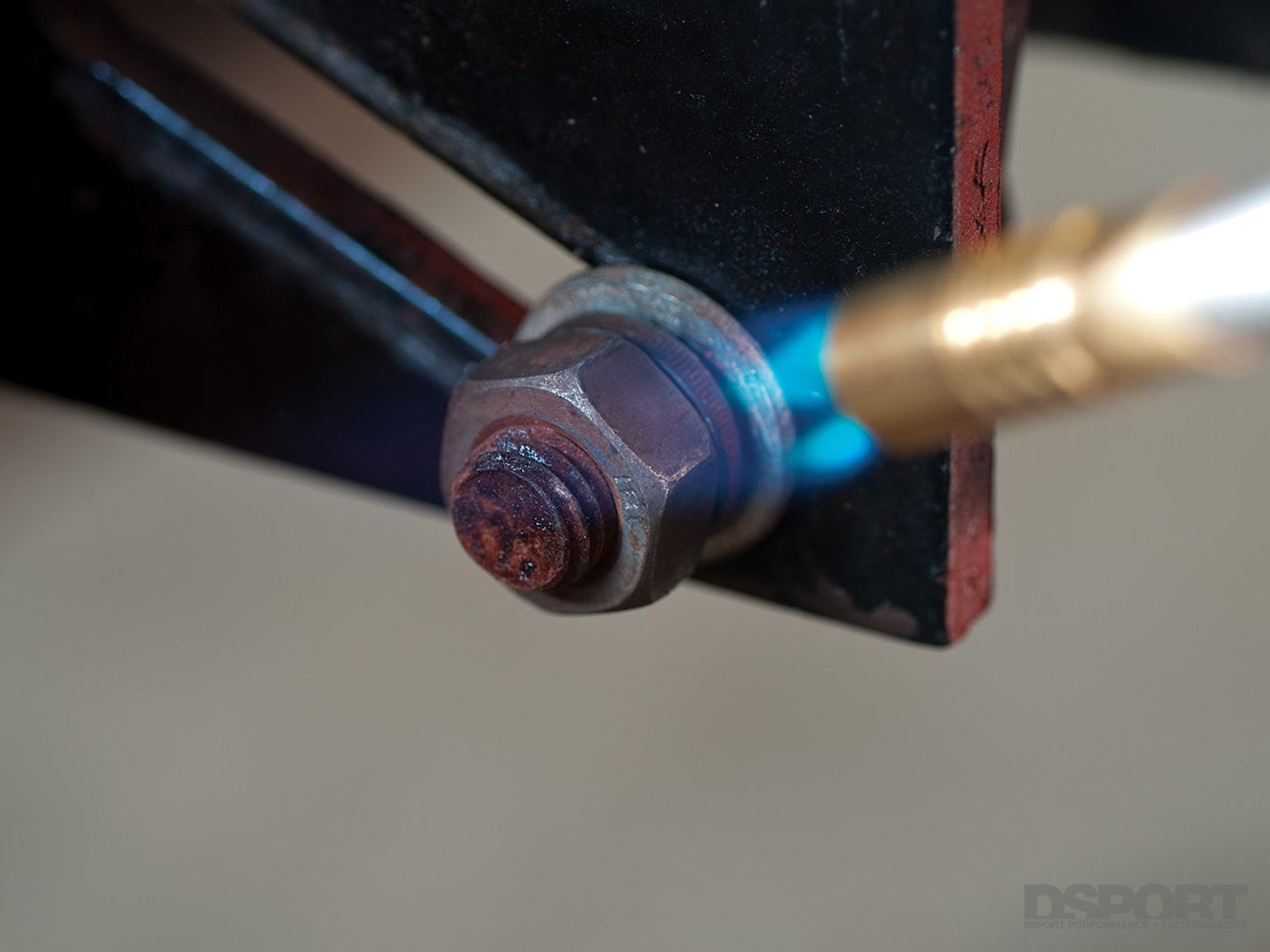

Hot Potatoes

When you’ve exhausted all of your options, it may be time bring out the big guns. Toys like a blow torch, a hammer or an impact wrench can often break the rust. Heat can often loosen up frozen fasteners, but it can also do serious damage to surrounding components, so extra care must be exercised. Paint and undercoating will almost always burn away before the bolt turns loose and sheet metal can easily deform under high temperatures. Use with extreme caution. When heat is applied to a nut, try to focus the heat on the nut and not the bolt. This will allow the nut to grow slightly larger expanding itself away from the threads of the bolt.

If heat fails to solve the problem, an air-powered impact wrench is a great way to break seized hardware free. Since not everyone has a shop-grade compressor and high-dollar tools lying around the garage, you can simulate how an impact wrench works with a simple hammer. Strike the head of the bolt with a solid blow, then try to turn bolt again. Repeat as necessary. Doing so will shock the corrosion and just might break everything loose.

If heat fails to solve the problem, an air-powered impact wrench is a great way to break seized hardware free. Since not everyone has a shop-grade compressor and high-dollar tools lying around the garage, you can simulate how an impact wrench works with a simple hammer. Strike the head of the bolt with a solid blow, then try to turn bolt again. Repeat as necessary. Doing so will shock the corrosion and just might break everything loose.

If you’ve tried all the other options and need a recommendation on an electric impact wrench, check out our review of the Milwaukee M18 FUEL Impact Wrench. When it comes right down to it, the best tool you can use to remove frozen hardware is determination. Don’t give up and use everything at your disposal. Try multiple combinations of these techniques and eventually the job will get done, even if that means having to replace the bolt in question.