Shooting the Juice

The fuel injector is the final piece of the fuel system puzzle that needs to be addressed when preparing your engine for high-horsepower production. There are four factors that determine the injectors you should purchase for your upgrade.

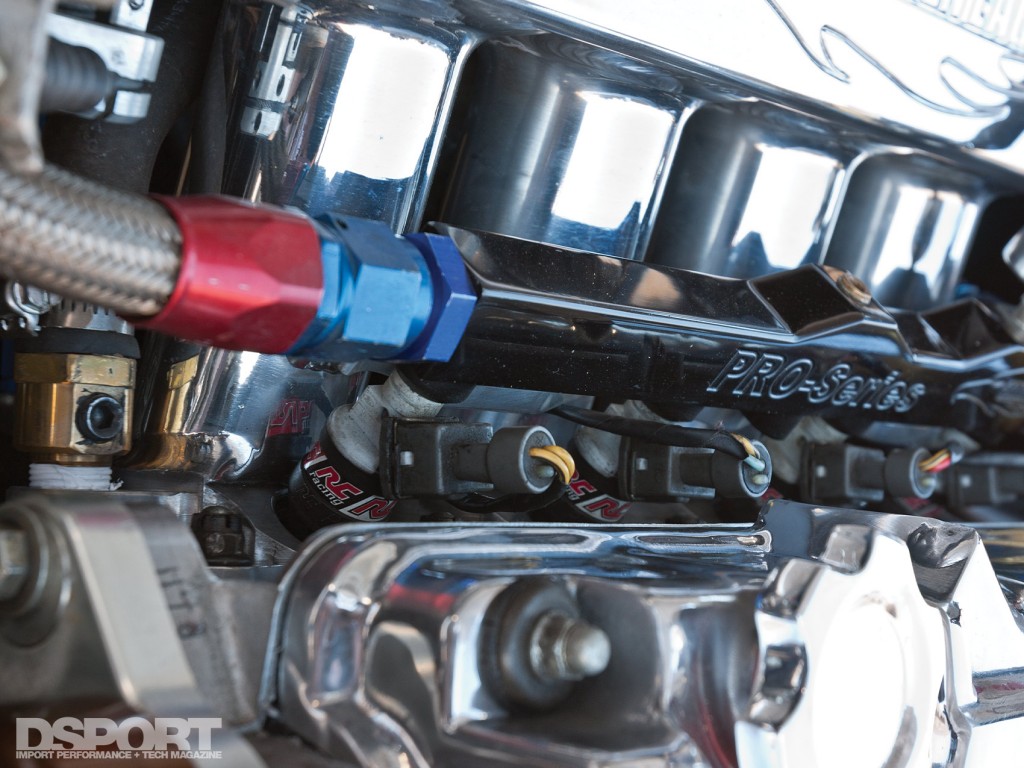

Merely having a set of aftermarket injectors means nothing if you can’t install them because they physically don’t fit your application. The two major types of fuel injectors are top-feed and side-feed. Top-feed is the choice most commonly used by OEM’s so that’s the injector style that’s most commonly purchased for upgrades. Although top-feed injectors are “fed” fuel from the same spatial location at the top of the injector, that doesn’t mean all top-feed injectors are physically interchangeable. Varying base and head diameters, different overall lengths and different injector clips may not allow one top feed injector to be installed in place of another. Side-feed injectors are less common, but still exist in some applications. Because of this, aftermarket side-feed injectors are more difficult to find than top-feed units. To increase the possible range of injectors available for your application, you might consider converting a side-feed injector system to a top-feed system with a conversion fuel rail. In spite of the additional cost of conversion, there might be a total overall savings from the relatively lower cost and availability of top-feed injectors.

Merely having a set of aftermarket injectors means nothing if you can’t install them because they physically don’t fit your application. The two major types of fuel injectors are top-feed and side-feed. Top-feed is the choice most commonly used by OEM’s so that’s the injector style that’s most commonly purchased for upgrades. Although top-feed injectors are “fed” fuel from the same spatial location at the top of the injector, that doesn’t mean all top-feed injectors are physically interchangeable. Varying base and head diameters, different overall lengths and different injector clips may not allow one top feed injector to be installed in place of another. Side-feed injectors are less common, but still exist in some applications. Because of this, aftermarket side-feed injectors are more difficult to find than top-feed units. To increase the possible range of injectors available for your application, you might consider converting a side-feed injector system to a top-feed system with a conversion fuel rail. In spite of the additional cost of conversion, there might be a total overall savings from the relatively lower cost and availability of top-feed injectors.

The second factor involves the electrical characteristics of the signal that drives the injector. Low-impedance, or peak-and-hold injectors are driven by a low electrical resistance signal on the order of 1.0 to 3.0 ohms. These injectors must have peak-and hold drivers or a resistor pack in the injector loom in order to be properly driven by the ECU. High-impedance or saturated injectors operate with an injector signal resistance generally between 12 and 16 ohms. Installing one injector type in place of the other may cause a failure of the injector drivers or the injectors themselves. It’s best to check the injector resistance with a volt-ohm meter before purchasing.

The second factor involves the electrical characteristics of the signal that drives the injector. Low-impedance, or peak-and-hold injectors are driven by a low electrical resistance signal on the order of 1.0 to 3.0 ohms. These injectors must have peak-and hold drivers or a resistor pack in the injector loom in order to be properly driven by the ECU. High-impedance or saturated injectors operate with an injector signal resistance generally between 12 and 16 ohms. Installing one injector type in place of the other may cause a failure of the injector drivers or the injectors themselves. It’s best to check the injector resistance with a volt-ohm meter before purchasing.

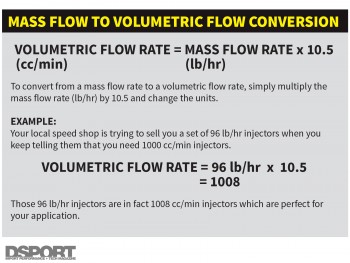

The flow rating of the injectors is another item that needs to be factored into your injector purchase. Some injector manufacturers rate their injectors based on a mass flow rate (which uses the units of pounds of gasoline per hour, abbreviated as lb/hr) instead of a volumetric flow rate (expressed in cubic centimeters per minute, cc/min). Because different fuels have different weights and specific masses, the volumetric flow rate is the preferred method of selecting the appropriate flow rate for your application.

The flow rating of the injectors is another item that needs to be factored into your injector purchase. Some injector manufacturers rate their injectors based on a mass flow rate (which uses the units of pounds of gasoline per hour, abbreviated as lb/hr) instead of a volumetric flow rate (expressed in cubic centimeters per minute, cc/min). Because different fuels have different weights and specific masses, the volumetric flow rate is the preferred method of selecting the appropriate flow rate for your application.

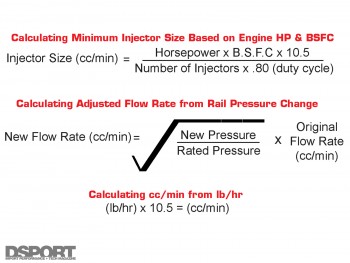

Finally, be sure that the injectors you choose will work at the higher fuel supply pressures that you intend to run your fuel system with. The relationship between fuel pressure and the change in the effective flow rate is not directly proportional. Doubling the fuel pressure from a base 40 psi to 80 psi will not allow the injector to double its flow rating. Small changes in the operating pressure can be used to adjust flow rates safely plus-or-minus 15 percent. Using the following equation and knowing the injector’s original flow rate, original test pressure and adjusted pressure you can calculate the injector’s effective flow rate. Keep in mind, however, that running pressures above the original factory pressure will reduce pump volume output so be sure your fuel pump can supply the additional volume at the maximum possible fuel pressure encountered.

The latest in fuel injector technology features high impedance injectors with flow rates capable of supporting in excess of 1,600 whp.

Call of Duty (Cycle)

Aside from the flow rate and pressure handling capabilities of the injector, the last component that needs to be factored in the interaction between the ECU and the injector driver. During each combustion cycle, the injector is open for a percentage of the total cycle time; this is what’s referred to as injector duty cycle. If an injector is operating at 50-percent (duty cycle) it’s being opened by the ECU for half the time available for it to be opened during the combustion cycle. As engine speed increases, the time in milliseconds for a complete combustion cycle decreases. This is why injector opening durations are described as percentages of the total available time for opening during combustion and not as a fixed duration in milliseconds.

Aside from the flow rate and pressure handling capabilities of the injector, the last component that needs to be factored in the interaction between the ECU and the injector driver. During each combustion cycle, the injector is open for a percentage of the total cycle time; this is what’s referred to as injector duty cycle. If an injector is operating at 50-percent (duty cycle) it’s being opened by the ECU for half the time available for it to be opened during the combustion cycle. As engine speed increases, the time in milliseconds for a complete combustion cycle decreases. This is why injector opening durations are described as percentages of the total available time for opening during combustion and not as a fixed duration in milliseconds.

For a large margin of safety, the factory ECU and injectors will most likely be set up to operate somewhere around 80-percent. At 80-percent duty cycle, the injector is still operating at a level that allows it to flow predictably. Above an 80-percent duty cycle, it is possible that the injector will be held open so long in a cycle that it will not have time to close adequately. So, at a 90-percent duty cycle, the injector might be open for 100-percent of the combustion cycle. To eliminate the possibility of losing control over the injectors, most tuners size the injectors to the system so that maximum operating duty cycle of the injectors stays at 80 or 85-percent.

The Last Squeeze

Although the injector is the last link in the fuel system chain, all the components of the chain deserve an equal amount of attention when it comes time to upgrade. Simply choosing one part without taking into account how it affects (and is affected by) the others in the system could lead you down the path of lost power potential and possible engine destruction.