With the original small block Chevy engines, priming the oiling system was an easy affair. A priming tool was sent down the hole where the distributor was normally located and a connection to the oil pump shaft was made. From there, you would fill the engine with oil and then use an electric drill to spin the oil pump’s shaft until oil pressure was achieved and oil made its way throughout the engine. If you wanted to be thorough, you could turn the crank with a rachet and socket after pressure was obtained to make sure oil was getting to all of the valvetrain too. You were effectively able to get the oiling system in full working order before you even attempted to crank the engine. With the LS engine, GM transitioned from a camshaft/distributor-driven oil pump to a crank-driven oil pump. Crank-driven oil pumps like those used on the “LS” are typical on most Japanese engines. While a crank-driven oil pump offers several advantages over a camshaft driven pump, crank-driven oil pumps do make priming the oiling system on a brand-new engine a bit more challenging. Since we just installed a new LS engine in our Escalade, we thought it would be a good opportunity to outline the proper way to prime a fresh LS or just about any import engine. Failure to follow a proper priming method WILL RESULT in major engine damage.

Text by Michael Ferrara // Photos by Staff

DSPORT Issue #231

The Worst Way

The worst way you can prime you new engine is to simply fill the oil in the engine to the proper level and then start the engine. The pump may require several hundred revolutions of the engine before it is able to draw oil through the pickup tube, fill the pump cavities with oil, then send out enough oil to fill all the oil galleys before the necessary amount of oil pressure is established. In effect, you shouldn’t even call this a priming method since no priming is taking place. This “worst” method relies upon the assembly lube and oil used during assembly to protect the rod and main bearings until oil pressure is established. If the engine fires up quickly, it may be at 600-to-1,200 RPM which means the crank is making 10 to 20 full rotations every second for the 30, 40 or 60 seconds it takes before oil pressure is realized. Expecting an assembly lube to provide protection during 1,200 rotations of a running engine is not realistic. When there is another issue with the engine (maybe a sensor is disconnected or has failed) that prevents the engine from starting, the engine is still being subjected to rotation without lubrication and load on the bearings whenever a cylinder is on the compression stroke.

A Slightly Better Way, But Not Ideal

While many experienced mechanics are smart enough to avoid the “Worst Way” to “prime” a new engine, the common practice is only slightly better. The slightly better method requires that all injectors be unplugged, power be disconnected from the ignition coils and spark plugs be removed from the engine. Unplugging the injectors prevents fuel from being injected into the cylinders, disconnecting power to the coils keeps you from getting shocked and removing the spark plugs prevents significant cylinder pressure from being created, since there is close to zero pressure in the cylinder when the cylinder pressures from being created when the engine is cranking. When the engine is cranked to “prime” the oiling system, the hope is that the assembly lube and oil used in the assembly process can protect the rod bearings, main bearings and valvetrain while the engine’s oiling system is getting primed and up to pressure. Unfortunately, the time it takes to prime the pump and get the oiling system up to pressure may still be more than the assembly lube can handle.

We have been using a GOODSON EPL-120 for a number of years to prime every new engine we’ve installed. It has a 12-quart capacity. The EPL-120 was recently replaced by a more compact 10-quart EPL-110. The EPL-110 retails for just under $280.

If you are priming and “breaking-in” a new engine, be sure to use a break-in oil. High-quality break-in oils like this Torco TBO 30W use a mineral base oil with an additive package optimizes for proper ring and cylinder wear

The Right Way

The priming technique used on the small block Chevy that used a drill to drive the oil pump delivered excellent results. This method ensured that all the oil galleys were filled with oil while also guaranteeing that the pump was primed. Since the LS engine and most import engines have the oil pump married to the crankshaft, there is no way to spin the oil pump without spinning the crankshaft. As a result, filling the oil galleys with pressurized oil requires some external assistance. This external assistance comes in the form of a pressurized vessel to deliver the oil into the engine’s oil galleys. Goodson and a few other companies offer dedicated engine oil priming vessels. An Accusump or Accumulator can also be used to prime the oiling system. All of these systems are available in various capacities with “the bigger the better” being the motto here. Ideally, the pressure delivery system will have a capacity that is equal to or greater than the oil capacity of the engine. If not, it will require multiple refills and pressurizations of the vessel to deliver the entire oil capacity of the engine in a pressured format.

A MOROSO Accumulator can not only be used to prime the oiling system on a new engine, it can also be installed to provide a number of other functions.

After the MOROSO Accumulator is filled with break-in oil, it can be pressurized with air to serve as the pressured vessel that primes the oiling system.

If the opportunity exists to watch the oil pressure during the process of pressurizing the system in this way, watch the gauge or data stream showing the oil pressure. During this process you should be able to reach 30-40psi of oil pressure on your gauge or sensor. This means that everything on the pressure side of the engine’s lubrication system will now be filled with oil. The pump and the pickup tube may also get filled during this process. However, since there isn’t a guarantee that the suction side of the system is primed, it is a good idea to follow up this pressurized priming with the previously described method of removing the spark plugs and disconnecting the injectors. Crank the engine only long enough to verify that oil pressure is being made. This may take 1 to 5 seconds. This process ensures that the oil pump on the engine can produce pressure. Once that is verified, reconnect the injectors, install plugs and fire up the engine for proper break-in.

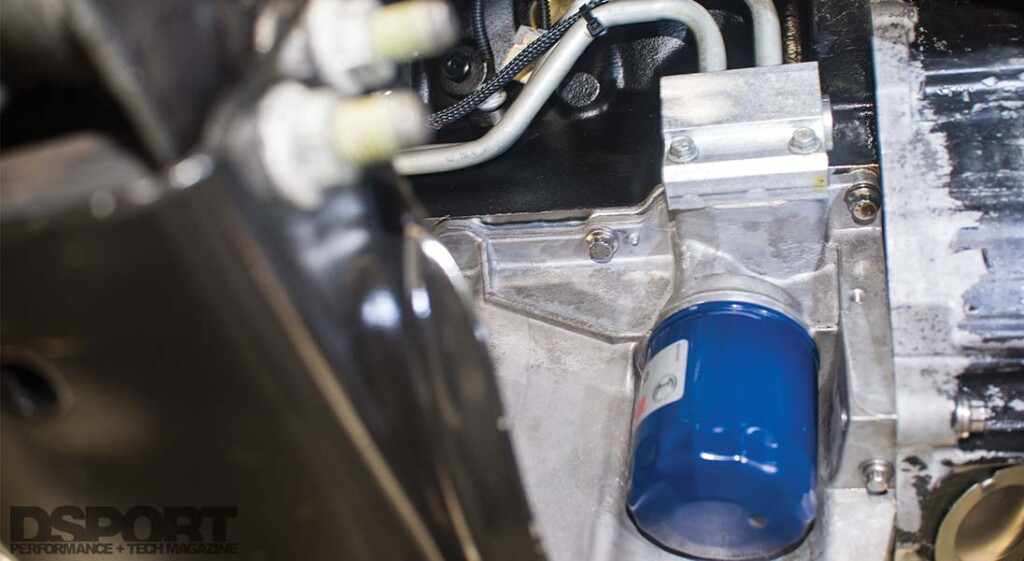

The oil cooler block off plate is a must on LS engines that use an oil cooler for priming to properly work. Fittings for a standard LS and a DART LS engine will differ.

Making the Connection

Since many Japanese engines are turbocharged, the connection to the engine’s main oil galley can often be sourced at the turbo oil feed line. With an LS engine, the process is a bit more involved especially on applications where the engine has factory oil cooler lines that plumb into the oil pan. To properly pressurize the oiling system with an external primer, an oil cooler block off plate must first be attached to the oil pan. These are available for under $20 from Amazon and several other sources. Next, a connection must be made into the main oil galley at the fitting just above the oil filter at the rear of the engine block. If you have a factory LS engine, a GOODSON EPL-LS1 fitting will be all that is needed to make the connection. If you have a DART SHP LS Next Pro block, the connection will require adapting from the O-ring to an -AN fitting. This is where the pressurized oil will be fed into the engine.

The factory oil cooler lines go into the oil pan on the Escalade. The oil lines must be removed and blocked off with a block-off plate during priming. This also allows better access to the main oil galley fitting located a few inches above the oil lines on the engine block. Be sure to get the proper fitting to tap into the galley.

The Bottom Line

There may be more than one way to skin a cat, but there is just one way to properly prime and engine with a crankshaft driven oil pump. If you are a shop owner that installs rebuild engines, invest in an oil priming solution. If you are doing a build yourself, invest in an Accusump or Accumulator. Not only will it work as an engine priming device, it can also be used as an engine pre-oiler and as a safety device to deliver pressurized oil during high G situations where the oil pickup becomes uncovered. After your engine is primed, make sure you follow the DSPORT procedure for engine break-in.