Often times, the simplest tasks could be the cause of extreme issues. Something as simple as removing some old paint using a traditional paint stripper could cause serious damage to humans when methylene chloride fumes are inhaled. After more than 64 horrific cases since 1980, something had to be done to remove paint more safely. In Club DSPORT, paint removal is one of the things we do on a daily basis. With our eyes peeled on the market for a safe solution, we found out about the Evapo-Rust SAFR finish remover. Safe, effective, and quick; SAFR has become our go-to solution for paint removal. Here’s what makes this product different and how we use it.

Text by Bassem Girgis // Photos by Joe Singleton

DSPORT Issue #233

We conducted our tests in an enclosed garage using proper protective equipment, including safety glasses and nitrile gloves. This paint remover contains hydrogen peroxide and will bleach skin if exposed. Wash your hands with soap and water after use.

The Safety

SAFR, which stands for Safer Automotive Finish Remover, uses powerful solvents to dissolve multiple layers of paint, while avoiding the hazards of older, traditional paint removal solutions. Designed to be safe indoors, this product does not give off noxious fumes or vapors. It has no n-Methyl Pyrrolidone, Methylene Chloride, Caustic Alkalis, Acids, or Harmful fumes. In addition to that, it is non-flammable. This addresses some of the fire incidents we’ve heard about when using acetone to remove paint. Instead, Evapo-Rust gets the paint off with ingredients such as Hydrogen Peroxide, Benzyl alcohol, water, proprietary non-hazardous polymer and detergent. With safety assurance, we wanted to find out if this product would work as well as the non-safe, proven-to-work products from the past.

SAFR, which stands for Safer Automotive Finish Remover, uses powerful solvents to dissolve multiple layers of paint, while avoiding the hazards of older, traditional paint removal solutions. Designed to be safe indoors, this product does not give off noxious fumes or vapors. It has no n-Methyl Pyrrolidone, Methylene Chloride, Caustic Alkalis, Acids, or Harmful fumes. In addition to that, it is non-flammable. This addresses some of the fire incidents we’ve heard about when using acetone to remove paint. Instead, Evapo-Rust gets the paint off with ingredients such as Hydrogen Peroxide, Benzyl alcohol, water, proprietary non-hazardous polymer and detergent. With safety assurance, we wanted to find out if this product would work as well as the non-safe, proven-to-work products from the past.

How it Works

We’ve tried several of Evapo-Rust’s products, and they are always straight forward in regards to their use. Evapo-Rust’s rust removal product was easy to use, but there were various ways of using it to achieve the same results depending on the extent of the paint. We wanted to see what the best way was to remove paint with SAFR. We’ve tried SAFR on both old paint and clear-coated finishes. The easiest way to remove paint is to brush the gel-like SAFR on the surface, wait for an hour until you see the paint bubble up, then scrape it off with a spatula. You should brush at least 3mm of the gel on the surface to cover the entire paint. Mask off all areas that you don’t want stripped so it doesn’t get removed in the process, then scrape away. The one hour could be extended up to overnight if you want an easier removal. While this process works, there is a slightly different process that makes it even easier to remove paint using SAFR.

A thick 6mm coat of SAFR gel will remove most automotive finishes, including powder coating, clear coats and ceramic finishes.

We placed the parts, wrapped in plastic, in a 150-degree Fahrenheit oven to speed up the chemical process.

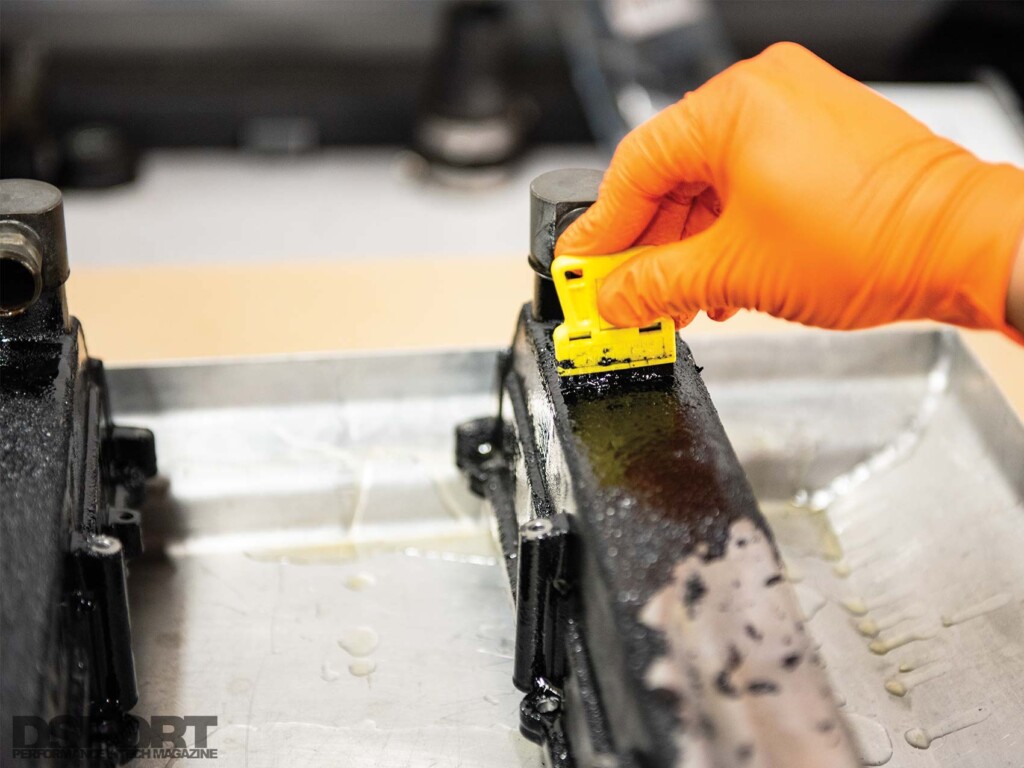

After allowing the part to cool down, we used a single edge plastic safety razor blade to scrape off the paint residue.

Washing the parts with warm soapy water and a nylon brush easily removed the last remnants of paint.

Ceramic Clear Coating

While this process works great, modern automotive finishes that include ceramic-type clear coating may need a different process, which happens to be the process we use. This process is recommended for modern ceramic auto paint. Steel, stainless-steel, and aluminum should be fine with the previous method. For the tougher paints, apply double the thickness (6mm) to the area you want to remove the paint from. Cover the area with a bag (you can use a trash bag), and lightly make contact with the bag and the surface. Don’t press too hard where you flatten the SAFR gel on the surface. Seal the bag shut so no air enters. Heat up the part to 150-170-degrees Fahrenheit for an hour. You can use a paint curing booth or a heat lamp, but if you don’t have either, you can put it in the sun for a while (if it’s hot out). Once you’re done with the heating process, let the part cool down for 5-minutes then remove the bag. The paint should be bubbling at this point. Use a spatula or a putty knife to scrape off the old paint.

Allow an hour for paint to release and crinkle. Multiple layers of paint may need longer release times. In our testing, the loosened paint effortlessly came off when scrapped.

Only a single application of the SAFR paint remover was necessary. Once washed and dried, no additional steps are necessary to neutralize the treated surface.

The Bottom Line

Traditional paint removers work and the results are visually clear, but it’s often what we don’t see happening that is most important. In this case, health damage could be the silent intruder. Just like you wear steel boots at a construction site, a helmet when racing, or gloves when you grab a hot pan; you should be using a paint remover that doesn’t harm your health. SAFR works the way it should, while being safe to use indoors. The peace of mind made it our go-to product to remove paint in the machine shop and made us advocates for it. In most cases, the process is simple and should be done in a couple of hours, but the thicker the paint, the more time it could take. In the end, your paint will be removed and you will live to paint the part again.