FROM AWD TO RWD

The main hurdle to clear for this project was the conversion from all-wheel drive to rear-wheel drive. This involved venturing outside most tuners’ comfort zone, as few have attempted to do so with the R35 chassis. After removing the GR6 transaxle at the rear, GReddy fitted an R34 GT-R differential carrier equipped with an OS Giken 2-way Super Lock limited slip differential to distribute power to the rear wheels. To transmit power from the VR38 engine to the new rear end, a custom OS Giken R3C racing clutch was bolted to the crankshaft to transfer torque to an OS88 sequential transmission. The transmission mates to the block by way of a custom bell housing and transfer case.

The main hurdle to clear for this project was the conversion from all-wheel drive to rear-wheel drive. This involved venturing outside most tuners’ comfort zone, as few have attempted to do so with the R35 chassis. After removing the GR6 transaxle at the rear, GReddy fitted an R34 GT-R differential carrier equipped with an OS Giken 2-way Super Lock limited slip differential to distribute power to the rear wheels. To transmit power from the VR38 engine to the new rear end, a custom OS Giken R3C racing clutch was bolted to the crankshaft to transfer torque to an OS88 sequential transmission. The transmission mates to the block by way of a custom bell housing and transfer case.

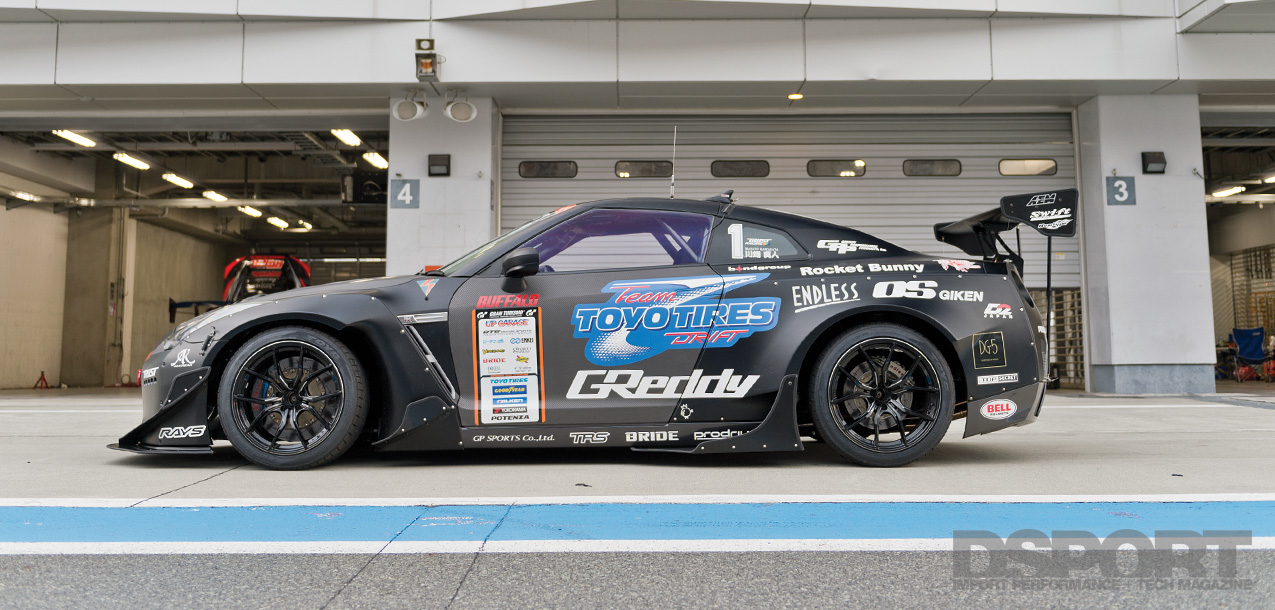

GREDDY LOVES GODZILLA

Since GReddy had already invested heavily into its development program for the R35 GT-R and its potent VR38DETT engine, the 35RX product line served as the source of many parts employed in the project. The foundation of the build started under the hood with a GReddy GR40 stroker engine. Since the factory engine block has proven capable of withstanding exceptional cylinder pressures while producing high output, GReddy elected to stick with the factory plasma lined cylinders and bore dimensions. A GR40 92.4mm crankshaft makes the connection to the GReddy connecting rods and forged aluminum pistons. Together, these components increased the displacement to four liters. To make best use of the increased displacement and to improve output and efficiency, higher lift, longer duration JUN AUTO camshafts replaced the factory bumpsticks in the heads.

Since GReddy had already invested heavily into its development program for the R35 GT-R and its potent VR38DETT engine, the 35RX product line served as the source of many parts employed in the project. The foundation of the build started under the hood with a GReddy GR40 stroker engine. Since the factory engine block has proven capable of withstanding exceptional cylinder pressures while producing high output, GReddy elected to stick with the factory plasma lined cylinders and bore dimensions. A GR40 92.4mm crankshaft makes the connection to the GReddy connecting rods and forged aluminum pistons. Together, these components increased the displacement to four liters. To make best use of the increased displacement and to improve output and efficiency, higher lift, longer duration JUN AUTO camshafts replaced the factory bumpsticks in the heads.

UNLEASHING THE FURY

Forcing air into the cylinders of the VR38 engine is the source of its incredible power production. With the right engine components in place, attention shifted to boost production, which fell on the shoulders of GReddy’s RX1200 turbochargers. Based on T88 SPL frames, these turbochargers hang from RX1200 exhaust manifolds and channel boost pressure forward to a GReddy SPEC-R intercooler. From the intercooler, the chilled aircharge enters the 35RX intake manifold to be distributed to the intake ports. The larger plenum volume of the manifold ensures sufficient volume is available to each runner for equal distribution to each combustion chamber. A six-pack of GReddy 1,200 cc/min injectors replaces the stock units, while the manifold features secondary injector ports in case more fuel delivery is needed. With a MoTeC M1 engine management system regulating fuel delivery and ignition events, the Spec-D spun the rollers of a Bosch dynamometer to 1,094 horsepower and 1,039 lb-ft torque.

Forcing air into the cylinders of the VR38 engine is the source of its incredible power production. With the right engine components in place, attention shifted to boost production, which fell on the shoulders of GReddy’s RX1200 turbochargers. Based on T88 SPL frames, these turbochargers hang from RX1200 exhaust manifolds and channel boost pressure forward to a GReddy SPEC-R intercooler. From the intercooler, the chilled aircharge enters the 35RX intake manifold to be distributed to the intake ports. The larger plenum volume of the manifold ensures sufficient volume is available to each runner for equal distribution to each combustion chamber. A six-pack of GReddy 1,200 cc/min injectors replaces the stock units, while the manifold features secondary injector ports in case more fuel delivery is needed. With a MoTeC M1 engine management system regulating fuel delivery and ignition events, the Spec-D spun the rollers of a Bosch dynamometer to 1,094 horsepower and 1,039 lb-ft torque.