LOYALTY TO THE LABEL. Many die-hard fans of specific brands will stick with them to the bitter end. Like many sport compact veterans, brothers Robert and Richard Wong have their roots in Hondas. Hondas were affordable, powerful and widely supported. Building serious Honda platforms was a hobby that delivered results.

When they were faced with the dilemma of building a new project, the brothers wanted to venture into the world of the rear-wheel drive. The Honda S2000 featured everything they desired: rear-wheel drive, balanced chassis, sleek body lines and the “H” badge on the front bumper.

Text and Photos by Richard Fong

Boosted F20C

The S2000 build began with this Sebring silver 2002 AP1 chassis. Seeking to maximize the output of the factory block, the engine internals remained in factory form. In preparation for forced induction, a Cometic 2mm head gasket replaced the factory shim to effectively drop the compression ratio to a more boost-friendly 10.0-to-1. ARP head studs were then chosen to secure the cylinder head to the block. With the block prepared, attention shifted to the power adder.

The F20C relies on a Full-Race turbo kit to generate force-induced horsepower

The F20C relies on a Full-Race turbo kit to generate force-induced horsepower

A properly-sized turbocharger can make a world of difference in the shape of the power curve. Since this S2000 would spend most of its time on the street, a responsive Garrett GT3076R ball-bearing turbocharger was selected for the job. The GT3076R hangs from a Full-Race stainless-steel manifold dressed in HPC ceramic coating. The heat insulating properties of the ceramic coating ensure that exhaust gases maintain maximum velocity as they reach the GT30’s turbine wheel. From the turbine outlet, spent gases flow through a Full-Race downpipe and custom 3-inch stainless-steel exhaust finished with an HKS Hi-Power muffler.

From the cool side of the turbo, the compressor draws fresh air through an AEM Dry-Flow filter and a 4-inch intake pipe. Once compressed, aluminum piping channels the pressurized air to the Full-Race front-mount intercooler. The cooled intake charge then flows through the factory throttle body and intake manifold en route to the combustion chambers. To manage the heat that the factory intake manifold absorbs, a NextGear Thermoshield intake manifold gasket replaced the factory gasket. As the air reaches the intake ports, a quartet of RCEngineering 750 cc/min fuel injectors spray 93-octane pump gas into the air stream.

From the cool side of the turbo, the compressor draws fresh air through an AEM Dry-Flow filter and a 4-inch intake pipe. Once compressed, aluminum piping channels the pressurized air to the Full-Race front-mount intercooler. The cooled intake charge then flows through the factory throttle body and intake manifold en route to the combustion chambers. To manage the heat that the factory intake manifold absorbs, a NextGear Thermoshield intake manifold gasket replaced the factory gasket. As the air reaches the intake ports, a quartet of RCEngineering 750 cc/min fuel injectors spray 93-octane pump gas into the air stream.

Delivering Results

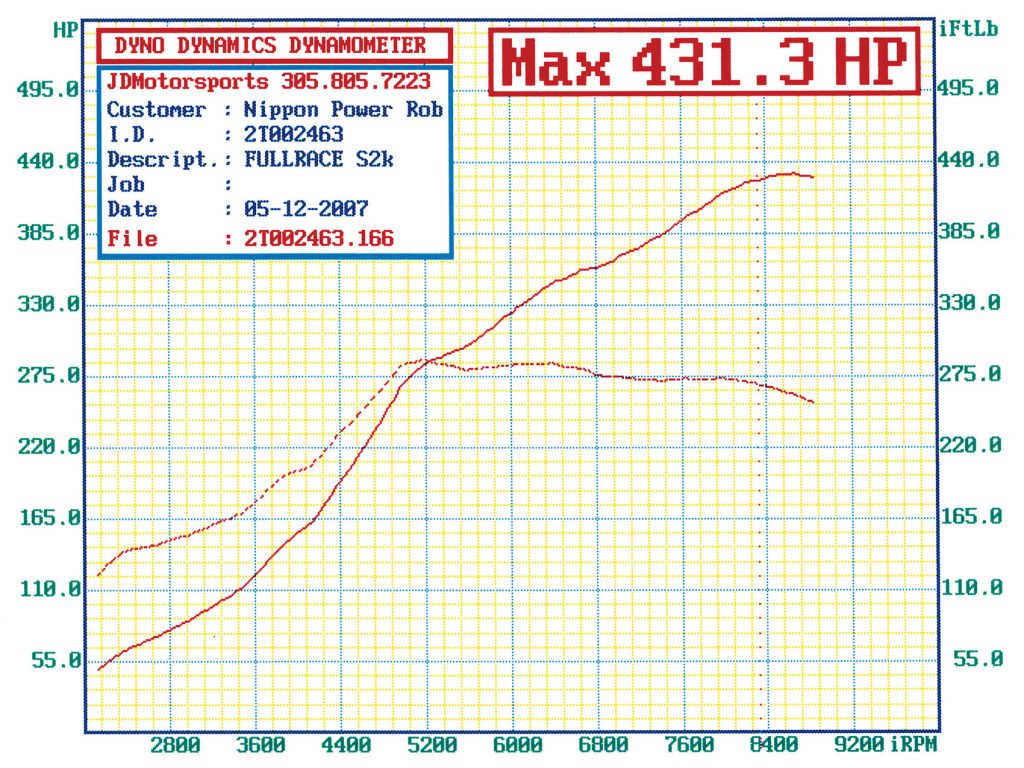

With the hard parts in place, coordinating fuel delivery and ignition timing events became the next hurdle to overcome. An AEM EMS stand-alone system replaced the factory engine management to orchestrate the injector duty cycles and ignition timing maps. With an AEM boost-control solenoid and a TiAL SPORT external wastegate keeping the boost pressure steady at 15 psi, JDM Motorsports tuned the EMS on a Dyno Dynamics dynamometer. Once optimized, the S2000 spun the rollers to the tune of 431 horsepower and 290 lb-ft of torque. Compared to the baseline of 190 horsepower and 127 lb-ft of torque, the F20C now generates 126-percent more power. Cool and Collected

With more than double the power, the engine develops significantly more heat than before. To keep temperatures in check, a Koyo aluminum radiator increases the capacity of the cooling system. Samco silicone hoses link the block to the radiator while Flex-a-lite dual electric fans maintains the air flow through the core. To further help with heat rejection, a Mocal oil cooler mounts neatly behind the bumper cover.

Power to the Pavement

Since the factory clutch can’t provide the clamping force necessary to deliver the horsepower to the wheels, the Wongs turned to ACT for a solution. ACT recommended a Pro-Lite flywheel and Heavy-Duty clutch to reinforce the S2000’s driveline. To maximize the performance potential of the driveline improvements, KW Variant-3 adjustable coilovers take the place of the factory dampers and springs at all four corners. Lowering the center of gravity and offering fully-adjustable compression and rebound dampening, the suspension keeps the S2000 planted around every turn. To improve the S2000’s contact patch with the road, 18-inch Volk Racing RE30 forged-aluminum wheels wrapped with 225/40R18 Yokohama S.Drive tires occupy the wheel wells up front and 245/35R18’s in the back. Taking advantage of the 18-inch rollers, a set of Project Mu 4-piston calipers apply pressure to Project Mu B-Force pads and 14-inch rotors up front while Power Slot rotors upgrade the rears. Project Mu Teflon brake lines sharpen brake response to the front calipers while Goodridge stainless-braided lines handle the duty at the rear.

Since the factory clutch can’t provide the clamping force necessary to deliver the horsepower to the wheels, the Wongs turned to ACT for a solution. ACT recommended a Pro-Lite flywheel and Heavy-Duty clutch to reinforce the S2000’s driveline. To maximize the performance potential of the driveline improvements, KW Variant-3 adjustable coilovers take the place of the factory dampers and springs at all four corners. Lowering the center of gravity and offering fully-adjustable compression and rebound dampening, the suspension keeps the S2000 planted around every turn. To improve the S2000’s contact patch with the road, 18-inch Volk Racing RE30 forged-aluminum wheels wrapped with 225/40R18 Yokohama S.Drive tires occupy the wheel wells up front and 245/35R18’s in the back. Taking advantage of the 18-inch rollers, a set of Project Mu 4-piston calipers apply pressure to Project Mu B-Force pads and 14-inch rotors up front while Power Slot rotors upgrade the rears. Project Mu Teflon brake lines sharpen brake response to the front calipers while Goodridge stainless-braided lines handle the duty at the rear.

The Finishing Touch

The exterior of the S2000 stays simple and clean. A Seibon carbon-fiber hood covers the engine bay, while a matching carbon-fiber hard top covers the cockpit. A Seibon spoiler sits atop the trunk lid to provide downforce and a more aggressive appearance. Craft Square carbon-fiber mirrors replace the stock pieces on the doors for an added degree of refinement. Inside the cabin, a pair of AEM Serial Datastream gauges takes their place on the A-pillar to deliver up-to-the-moment engine vitals.

The exterior of the S2000 stays simple and clean. A Seibon carbon-fiber hood covers the engine bay, while a matching carbon-fiber hard top covers the cockpit. A Seibon spoiler sits atop the trunk lid to provide downforce and a more aggressive appearance. Craft Square carbon-fiber mirrors replace the stock pieces on the doors for an added degree of refinement. Inside the cabin, a pair of AEM Serial Datastream gauges takes their place on the A-pillar to deliver up-to-the-moment engine vitals.

Loyalty Rewarded

While this build began as a personal project vehicle, it had grown into a representative for Robert and Richard’s company, Nippon Power. These days, the Honda spends most of its days in the garage away from the elements. On select days, the S2000 makes appearances at local shows and the occasional Hot Import Nights event. Fortunately, this Honda gets to where its going by driving the streets and not piggyback on a trailer. That’s the right way or “Wong” way to get it done.

SPEC SHEET

| VEHICLE | |

|---|---|

| Year / Make / Model: | 2002 Honda S2000 |

| Chassis Code: | AP1 |

| Vehicle Weight: | 2,800 lbs |

| Shift RPM: | 9,200 RPM |

| Redline RPM: | 9,200 RPM |

| ENGINE | |

|---|---|

| Engine Code: | F20C |

| Displacement (cc): | 1,997cc |

| Bore & Stroke (mm): | 87mm x 84mm |

| Peak Horsepower (@ RPM): | 431 whp @ 8,720 RPM |

| Peak Torque (@ RPM): | 290 lb-ft @ 5,200 RPM |

| Dyno Type: | Dyno Dynamics |

| Cylinder Head Mods / Gasket: | Cometic 2mm Head Gasket |

| Head / Main Studs: | ARP Head Studs |

| Intake System: | AEM Dry Flow 4-inch Filter |

| Custom 4-inch Intake Pipe | |

| Fuel Injection: | RC Engineering 750 cc/min Injectors (x4) |

| Fuel Delivery: | Walbro 255 lph In-tank Fuel Pump |

| Engine Management: | AEM EMS Sensor |

| Boost Controller: | AEM Boost Control Solenoid |

| Spark Plugs: | NGK BKR7E Spark Plugs |

| Turbocharger(s): | Full Race Stage-2 GT Turbo Kit |

| HPC Ceramic Coated | |

| Turbocharger Information: | Garrett GT3076R |

| Frame | T3 |

| Compressor Wheel Specs: | 76.2mm Major, 57mm Minor |

| Turbine Wheel Specs: | 60mm, 84 Trim |

| Turbine Housing: | .63 A/R |

| Exhaust Manifold: | Full Race Stainless Manifold |

| Wastegate: | TiAL Sport 44mm Wastegate |

| Blow-Off Valve: | Synapse Synchronic Blow-Off Valve |

| Exhaust System / Downpipe: | Full Race Downpipe |

| CHASSIS/DRIVELINE | |

|---|---|

| Springs, F&R (Make & Rate): | KW Suspension 515 lbf/in Springs |

| Shocks, F&R (Make & Rate): | KW Suspension Variant-3 Coilovers |

| Transmission Gearing: | 3.133; 2.045; 1.481; 1.161; |

| 0.970; 0.810 | |

| Final Drive: | 4.1:1 |

| Clutch / Flywheel: | ACT Heavy-Duty Clutch |

| ACT Pro-Lite Flywheel | |

| Wheels (Make, Size & Offset): | Volk Racing RE30 Forged Wheels |

| 18×7.5-inch +50mm (F) | |

| 18×8.5-inch +52mm (R) | |

| Tires (Make & Size): | Yokohama S.drive |

| 225/40R18 (R), 245/35R18 (R) |

| INTERIOR | |

|---|---|

| Gauges: | AEM Serial Datastream Gauges |

| Etc.: | Factory AP2 Radio Cover |

| Factory AP2 Center Console | |

| JDM FD2 CTR Bronze 6spd Shift Knob |

| EXTERIOR | |

|---|---|

| Hood: | Seibon Carbon-Fiber Hood |

| Spoiler: | Seibon Carbon-Fiber Rear Wing |

| Headlights: | AP2 Headlight Conversion |

| PIAA Ion Plasma H1 Bulbs |