From the Dyno to the Strip

| The Timeslip | ||

|---|---|---|

| 60′ | 1.819 | |

| 330′ | 4.885 | |

| 660′ | 7.456 | |

| 1/8 mile | 95.29 mph | |

| 1320′ | 11.578 | |

| 1/4 miile | 120.36 mph | |

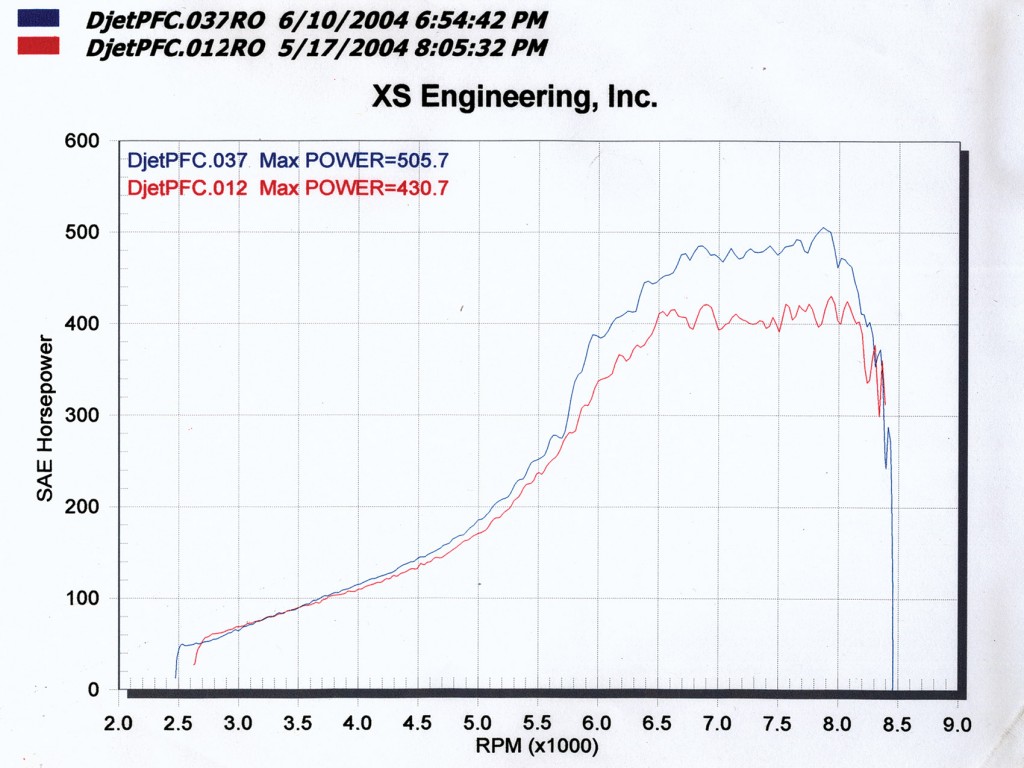

After tuning the Power FC to produce 505 wheel horsepower on performance- inhibiting 91 octane pump gas, it was time to get Project RH9 GT-R back to the track. On June 5th and again on June 12th, we set off to Carlsbad Raceway near San Diego, California. These trips marked the first dragstrip visit for the GT-R since November of 2002. On that prior visit, our Nissan had obliterated its first factory transmission. With our Holinger 6-speed sequential in place, we drove our GT-R to the dragstrip for an afternoon of fun. It was refreshing to be racing at a dragstrip instead of running an event. The best pass of the two trips was an 11.57 at just under 120mph. This was obtained with a tire-spinning 1.8-second 60-foot time. This 60-foot time was far from optimized as we purposely biased the power to the rear wheels with the Field electronic torque split controller. The purpose of this strategy was to save the factory front axles which have not yet been upgraded. It’s our hope that Moore performance will finalize the upgraded axels for the GT-R in the next few weeks. With stronger axles in place and the power evenly distributed to all four wheels, we believe we can get 60-foot times in the 1.7- to 1.6-second range on the BFGoodrich G-force KD 265/35ZR18 tires.

Dragstrip & Dyno:Our Classroom

Every session on a dyno or visit to a dragstrip provides a performance education. We answer many questions that we have and usually are prompted to come up with a new set of questions. Our dyno experience proved that there was more performance that could be extracted with a better intake system. The session also made us believe that additional power could also be realized by upgrading the ignition system. With the stock cams, an upgraded ignition system and a final round of Power FC tuning, we would expect to see 520 to 530 horsepower at the wheels with 91-octane pump gas. To go beyond this, we plan on installing a set of A’PEX Integration camshafts. These low-lift camshafts fit into the factory head without machining or excessive re-shimming of the valvetrain (a necessary operation when mid or high-lift cams are installed). We opted for a 270 degree intake and 280 degree exhaust combination. The cams should shift the peak power up by about 1000 rpm based on the duration increase. With a set of the A’PEX VMAX valve springs, the engine should be able to spin to 9000 rpm. With the cams in place, 550-to-600 horsepower may be realized on pump gas. That will be enough power to get the car into the 10s on pump gas.

Every session on a dyno or visit to a dragstrip provides a performance education. We answer many questions that we have and usually are prompted to come up with a new set of questions. Our dyno experience proved that there was more performance that could be extracted with a better intake system. The session also made us believe that additional power could also be realized by upgrading the ignition system. With the stock cams, an upgraded ignition system and a final round of Power FC tuning, we would expect to see 520 to 530 horsepower at the wheels with 91-octane pump gas. To go beyond this, we plan on installing a set of A’PEX Integration camshafts. These low-lift camshafts fit into the factory head without machining or excessive re-shimming of the valvetrain (a necessary operation when mid or high-lift cams are installed). We opted for a 270 degree intake and 280 degree exhaust combination. The cams should shift the peak power up by about 1000 rpm based on the duration increase. With a set of the A’PEX VMAX valve springs, the engine should be able to spin to 9000 rpm. With the cams in place, 550-to-600 horsepower may be realized on pump gas. That will be enough power to get the car into the 10s on pump gas.

As for the 9s, race gas may make it a reality on the stock short block. However, we already have received the ARP head studs and Cometic gasket that will be part of the “built” engine that will hopefully be completed by year end.