Upgraded Cooling System

Currently, we can generate over three times the original horsepower output of the engine. Generating three times the power also means that we are generating triple the amount of rejected heat to the engine’s cooling system. An upgrade was definitely in order, so we decided to do it right the first time.

The core of an automotive cooling system is the radiator. The radiator is where the heat from the engine’s cooling system gets rejected to the atmosphere (the air passing through the radiator core to be more specific). A radiator’s construction and design will determine its efficiency in rejecting the excess heat from the radiator to the surrounding air. When a radiator is designed and built, the core can be manufactured to an optimum thickness and cooling-fin density.

The core of an automotive cooling system is the radiator. The radiator is where the heat from the engine’s cooling system gets rejected to the atmosphere (the air passing through the radiator core to be more specific). A radiator’s construction and design will determine its efficiency in rejecting the excess heat from the radiator to the surrounding air. When a radiator is designed and built, the core can be manufactured to an optimum thickness and cooling-fin density.

The purpose of the engine cooling fan is to induce airflow over the radiator. On the RB26DETT engine in our Skyline, a viscous clutch fan attaches to the water pump pulley and is driven by a V-belt from the crankshaft. It’s a simple and pretty effective design; however it has its drawback. For one, the factory fan is a bit on the noisy side when compared to electric fans. Additionally, the engine mounted fan takes horsepower to spin whereas an electric fan doesn’t tax the engine in the same way.

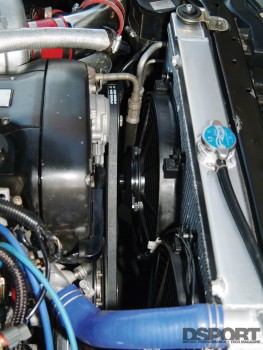

We had a number of options when it came to choosing a radiator and electric fan combination for our project GT-R. A number of Japanese companies produce high-performance radiators and there quite a few electric fan companies too. After establishing a good relationship with Fluidyne from all of the IDRC events that they support, we contacted Fluidyne to see if they had any interest in producing a direct-fit, high-performance replacement radiator for our Project GT-R. Even though there is a limited market for GT-R radiators in the states, Fluidyne was happy to become involved in hopes of expanding there overseas sales. One of the nice parts about the high-performance radiators from Fluidyne is that all of the original parts bolt directly in place.

We had a number of options when it came to choosing a radiator and electric fan combination for our project GT-R. A number of Japanese companies produce high-performance radiators and there quite a few electric fan companies too. After establishing a good relationship with Fluidyne from all of the IDRC events that they support, we contacted Fluidyne to see if they had any interest in producing a direct-fit, high-performance replacement radiator for our Project GT-R. Even though there is a limited market for GT-R radiators in the states, Fluidyne was happy to become involved in hopes of expanding there overseas sales. One of the nice parts about the high-performance radiators from Fluidyne is that all of the original parts bolt directly in place.

As for the fans, Flex-A-Lite (FAL) was contacted to provide the electric fans that would replace the archaic belt-driven fan currently in place. To ensure that we ordered the correct fans, we measured the radiator core and compared it to the FAL catalog to choose the correct parts. A pair of 12-inch slimline fans would be the hot ticket for this application.

Installation of the Fluidyne radiator and FAL fans was very easy. All the parts fit extremely well. We decided to locate the fan relay and fuse assembly in the factory fuse box to keep the wiring as clean as possible.

We filled our cooling system with distilled water, Prestone anti-rust and Royal Purple Purple Ice cooling system additive. It’s a great mix for any area that doesn’t experience freezing temperatures. Depending on where you live and the time of year, you may need to consider adding antifreeze to the mix. However, if you go to the dragstrip, be sure to drain out the coolant and replace it with distilled water in case any cooling system leaks occur on the track.

How does our new cooling system work? Actually, it’s working extremely well so far. By eliminating the engine- driven fan, the engine seems to rev up easier. The FAL fans are surprisingly quiet (we have the standard version blades, not the S-blades that are designed to be even quieter). Engine cooling temperatures are slower to climb under heavy load conditions too. We’ve freed up some horsepower and gained some additional reliability, it’s been a great addition.

More Boost

Now everything that we have spoken about so far makes plenty of sense. However, there is one thing that still has us scratching our heads. Before this round of modifications, we could generate a maximum of about 7 to 8psi of boost pressure on the two-step rev limiter. Now, we can get 14 to 15 psi on the two-step. This is enough boost pressure to generate the power needed to break loose all four wheels on the launch. Stay tuned as we try to solve this mystery and more with our Project RH9 GT-R.