REFRESH, REBUILD OR REUSE?

| TABLE A (For OBD1 B16A3 and B17A1 Only) | |

|---|---|

| Oil Pump Assembly | pn 15100-PR4-A03 |

| Oil Pan Gasket | pn 11251-P30-004 |

| Thermostat Assembly | pn 19301-PAA-306 |

| Timing Belt | pn 14400-P2T-004 |

| Timing Belt Tensioner | pn 14510-P30-003 |

| Valve Cover Gasket Set | pn 12030-P30-000 |

| Water Pump | pn 19200-P30-003 |

After acquiring the engine and transmission for your swap, you’ll really need to consider how much money you want to invest in the engine. Although a JDM engine with low miles may not require many replacement parts, most USDM engines of that era have high-mileage and years of abuse. Depending on the condition of your engine, you’ll need to source the respective replacement parts. Although some people will simply drop an engine into the vehicle without going through it, we strongly recommend replacing at least a handful of wear components that are notorious for failing. Take a look at Table A for all of the components we recommend as a minimum replacement.

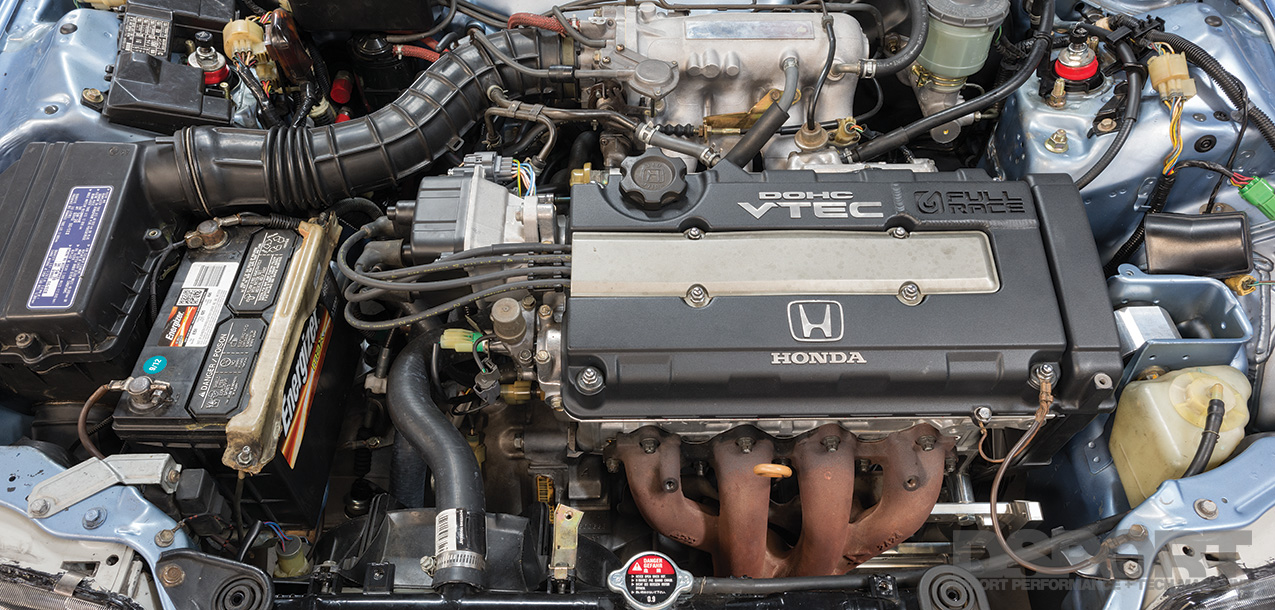

In addition to increased performance, Project CR-X will also serve as the test bed for a B-series camshaft shootout, nitrous testing and other power adders, we decided to fortify the internals of the B17A1. This meant a complete teardown of the engine to just the bare block was in order. After popping the valve cover off and taking a look at the camshaft follower pads, it looked like this engine was a winner. Little-to-no wear on the pads indicated that the engine had relatively low miles for its age and the lack of sludge made it clear that the engine oil had been changed regularly.

In addition to increased performance, Project CR-X will also serve as the test bed for a B-series camshaft shootout, nitrous testing and other power adders, we decided to fortify the internals of the B17A1. This meant a complete teardown of the engine to just the bare block was in order. After popping the valve cover off and taking a look at the camshaft follower pads, it looked like this engine was a winner. Little-to-no wear on the pads indicated that the engine had relatively low miles for its age and the lack of sludge made it clear that the engine oil had been changed regularly.

THE BOTTOM END

Although the engine passed a visual inspection, the cylinders were slightly out of round and required a fresh hone. This meant that we needed a slightly larger piston to maintain tight clearances. To this end, we chose a set of .5 mm oversize forged Arias 81.50mm +2cc medium compression pistons (p/n 3330411). While the emissions referees may not condone changing pistons or compression ratios, you won’t have any problems passing emissions as long as you’re within .5 of the original compression ratio.

To complement the Arias pistons, we upgraded the factory rods with ARP2000 rod bolts (p/n 208-6401) and some trick rod bushings. Unlike the factory piston and rod combination that utilizes a press-fit wrist pin to the rod, we machined it out and re-bushed it with a set of rod bushings from CP-Carrillo (p/n BSH-SB-880x800x1000). With the bushings installed and an oiling hole added for increased lubrication, the bottom end came together with the factory B17 crankshaft and a set of new OEM Honda main and rod bearings. Instead of purchasing a new oil pump, we inspected the used unit and refreshed it with a new main seal and sealed it against the engine block with ThreeBond liquid gasket (p/n 1104, gray) for leak-free operation.

To complement the Arias pistons, we upgraded the factory rods with ARP2000 rod bolts (p/n 208-6401) and some trick rod bushings. Unlike the factory piston and rod combination that utilizes a press-fit wrist pin to the rod, we machined it out and re-bushed it with a set of rod bushings from CP-Carrillo (p/n BSH-SB-880x800x1000). With the bushings installed and an oiling hole added for increased lubrication, the bottom end came together with the factory B17 crankshaft and a set of new OEM Honda main and rod bearings. Instead of purchasing a new oil pump, we inspected the used unit and refreshed it with a new main seal and sealed it against the engine block with ThreeBond liquid gasket (p/n 1104, gray) for leak-free operation.