While the ignorant V8 “Mountain-Motor” camp still spouts the “There’s no replacement for displacement” mantra, various methods of forced-induction have proven to be the perfect substitutes for cubic inches. Turbochargers, along with positive displacement and centrifugal superchargers, have allowed small-displacement engines to multiply their naturally-aspirated output. When the desired power increases are on the order of 50-to-100-percent over the “all-motor” output, a properly-sized and well engineered turbocharger or supercharger system can generally provide the desired performance increase without a significant trade off in engine response. However, when the output of the engine is going to be doubled, tripled or quadrupled, a big turbocharger or massive centrifugal supercharger is required. While these components will add significant power gains at higher engine speeds, both will generally experience some degree of boost lag at low-to-mid-range engine speeds. With only limited amounts of additional air being forced into the engine at the lower RPMs, the additional horsepower and performance realized is limited.

Text and Photos by Michael Ferrara

THE FAT SOLUTION

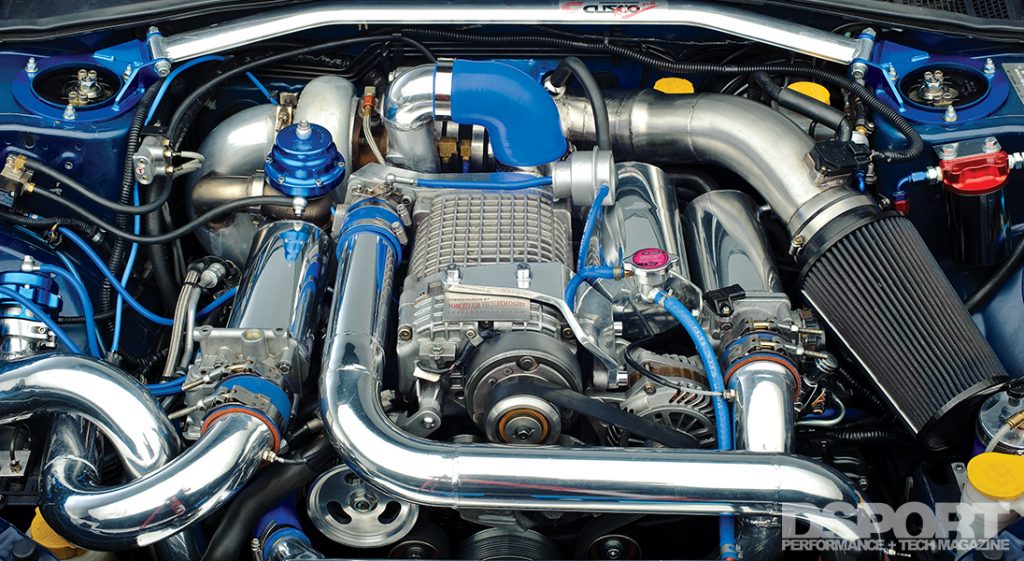

Forced Air Technologies (FAT) of Phoenix, Arizona decided a combination of two different forced-induction technologies would provide the optimum in boost and engine response. A positive-displacement supercharger and high-efficiency turbocharger would be integrated in a quasi-sequential system that would take the strengths of each system to mask the weaknesses of the other.

SUPERCHARGER: POSITIVE-DISPLACEMENT FOR INSTANT BOOST

The main advantage of a positive-displacement supercharger is that it delivers a boost in performance instantly. This allows the boost pressure and power output of the engine to be increased regardless of the engine speed. While providing the ultimate in response, there are drawbacks to this technology in comparison to a centrifugal supercharger or turbochargers. First, the flow capacity of most positive-displacement superchargers is generally less than a more-compact centrifugal supercharger or turbocharger. Second, the efficiency of this type of supercharger is often considerably less than that of a centrifugal supercharger or turbocharger. Due to this lower efficiency, more horsepower is stolen from the crankshaft to drive the compressor that delivers the additional air into the engine. Lower efficiencies also mean that the compressor outlet temperatures are higher for a given engine power output.

The main advantage of a positive-displacement supercharger is that it delivers a boost in performance instantly. This allows the boost pressure and power output of the engine to be increased regardless of the engine speed. While providing the ultimate in response, there are drawbacks to this technology in comparison to a centrifugal supercharger or turbochargers. First, the flow capacity of most positive-displacement superchargers is generally less than a more-compact centrifugal supercharger or turbocharger. Second, the efficiency of this type of supercharger is often considerably less than that of a centrifugal supercharger or turbocharger. Due to this lower efficiency, more horsepower is stolen from the crankshaft to drive the compressor that delivers the additional air into the engine. Lower efficiencies also mean that the compressor outlet temperatures are higher for a given engine power output.

TURBOCHARGER: HIGH-EFFICIENCY AND CAPACITY FOR BIG POWER

Turbochargers and centrifugal superchargers both have the advantage of higher efficiency compressor sections when compared to a positive displacement supercharger. As a result, compressor outlet temperatures are lower for a given boost pressure. In addition, less power is used to drive the compressor for a given flow. While turbochargers share similar technology in the compressor section when compared to a centrifugal supercharger, turbochargers are unique in the method used to drive the compressor. In essence, turbochargers are really two technologies in one; a compressor and a turbine. By using the energy in the exhaust gasses to drive the turbine (that in turn drives the compressor), “energy recovery” or “free horsepower” is realized. Of course, there are drawbacks to turbocharging. Since the turbine is dependent upon exhaust gas flow to drive the compressor, any condition where exhaust flow is limited will limit the output of the compressor. When “big” turbochargers with larger compressor sections are employed to make big power numbers on small engines, a turbocharger may not be able to generate appreciable boost pressures until higher engine speeds where exhaust flow is optimal. The end result is often a very narrow power band that spreads across a couple thousand RPM before redline in extreme cases.

INTEGRATION: ELECTRIC CLUTCH, BYPASS AND BOOST CONTROL

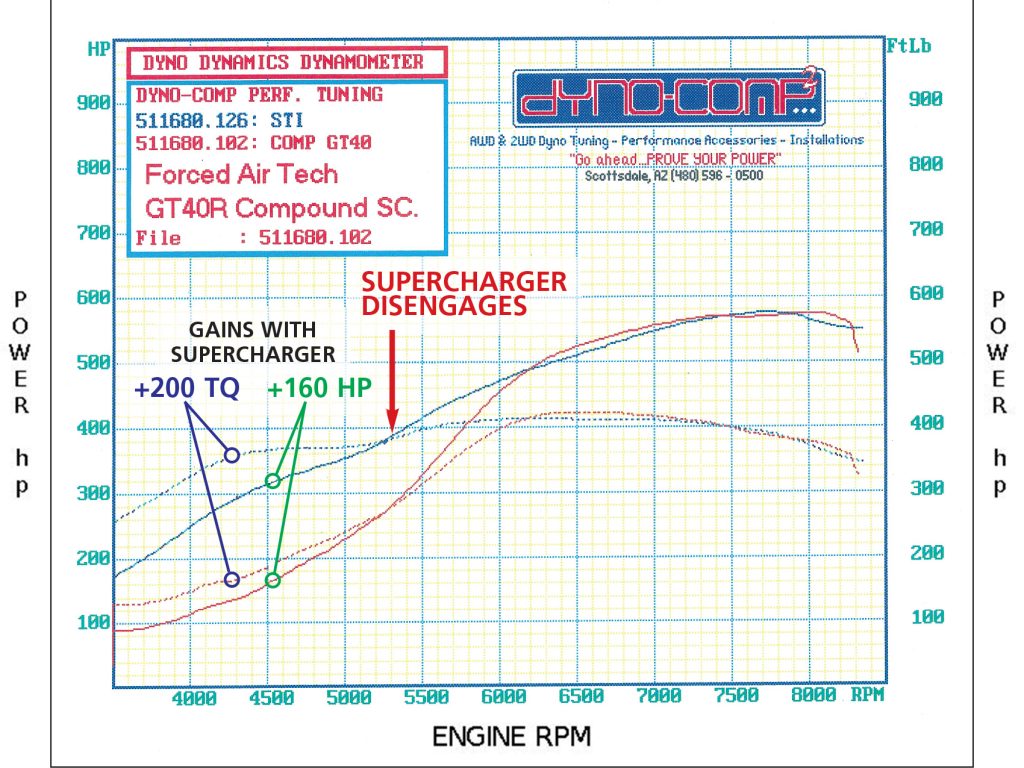

The FAT strategy for delivering the best of both worlds involves using the supercharger at low engine speeds until exhaust flows are high enough to let the big turbocharger take over. To make this strategy a reality, a positive-displacement supercharger fitted with an electric clutch would be a must. FAT chose the supercharger used on the Mercedes Benz C32 AMG and SLK32 AMG. This supercharger allows the Mercedes Benz 3.2-liter V6 engine to make about 350 horsepower. To extend supercharger life and improve fuel economy, the supercharger uses a clutch to reduce parasitic drag during cruise operation. FAT uses this clutch system to deactivate the supercharger once boost pressure has reached the target level. Once deactivated, the big Garrett GT4088R takes over. At 32 psi of boost pressure, the GT4088R delivers enough airflow to allow 604 horsepower to be realized at the wheels on the Dyno Dynamics AWD dyno. This is a 163- percent gain over the 230 whp measured in stock form.

SIDEBAR: BUDGET BOOST ASSIST

Over three years ago in our June 2007 issue (#54), we tested a ZEX Turbo Nitrous System (p/n 82218) on our Project RH9 GT-R. The resulting performance gains from this system were phenomenal. With a street price of just under $600 and an install time of a few hours, this ZEX system was the perfect adrenaline boost for our big-and-lazy twin-turbo combination.

Working in a similar fashion to the supercharger and turbocharger combination used on this STI, the nitrous-oxide system took the same role as the supercharger. The ZEX Turbo Nitrous System would inject nitrous-oxide and fuel until the target boost pressure was realized. At that point, the nitrous-oxide

system would shut off and let the big turbos do their job. How well did the system work? On a constant-load dyno pull, the engine reached peak horsepower eight seconds sooner with the ZEX Turbo Nitrous System than without. Despite a conservative 75-horsepower jetting, the system actually allowed the engine to produce an additional 120 horsepower at the wheels at 5,000 RPM. The reason was simple. With the nitrous system activated at 3,500 RPM, the boost pressure was up to 13.2 psi (instead of just 7.8 psi) at 5,000 RPM.Of course there are some limitations with a ZEX Turbo Nitrous System. First, the system should not be activated at engine speeds that are too low. In the case of our 10,000 RPM GT-R engine, we used a window-RPM switch to limit the turn-on RPM between 3,500 RPM and 9,600 RPM. Second, the bottle will eventually run out and need to be filled. In the case of a 75-horsepower shot, a bottle will last for about 45 2.5-second assists.

MISSION ACCOMPLISHED

While the end result of combining two different forced-induction technologies seems simple, the reality is that an immense amount of research, engineering, planning and development needed to take place to make everything work right. Simply fitting the supercharger under the factory hood was a challenge that would have driven a number of fabricators to call it quits. Getting the engine management and boost control systems to work in perfect unison was also a major challenge. However, the hard work paid off as the 2.5-liter engine now has the bottom-end torque curve of a 4.0-liter V8 with over 600 horsepower on the top end. There are replacements for displacement.

SPEC SHEET

| VEHICLE | |

|---|---|

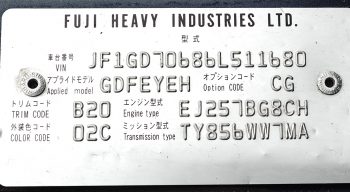

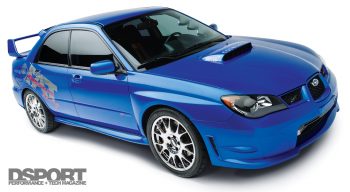

| Year / Make / Model: | 2006 Subaru WRX STi |

| Chassis Code: | GDB |

| Vehicle Weight: | 3,300 lbs. |

| Launch RPM: | 4,200 RPM |

| Shift RPM: | 8,250 RPM |

| Redline RPM: | 8,500 RPM |

| Peak Boost: | 32 psi |

| Fuel: | VP Racing Q16 Race Fuel |

| ENGINE | |

|---|---|

| Engine Code: | EJ257 |

| Displacement (cc): | 2,457.4cc |

| Bore & Stroke (mm): | 99.5mm x 79mm |

| Peak Horsepower (@ RPM): | 604.6 whp @ 7,700 RPM |

| Peak Torque (@ RPM): | 440 lb-ft @ 6,700 RPM |

| Dyno Type: | Dyno Dynamics |

| Engine Builder: | Robert Ansick of Forced Air Technologies (FAT) |

| Block Modifications: | Time Cert Inserts Custom-tapered Darton Sleeves |

| Machine Work: | Custom T oiling drilled galleys in crank |

| Pistons / Compression Ratio: | Wiseco Pistons 8.9:1 Compression |

| Connecting Rods / Crank: | Eagle Connecting Rods ARP 2000 Main Bolts |

| Camshafts: | Cosworth 272-degree Camshafts |

| Valves / Springs / Retainers: | Cosworth Dual Valve Springs and Titanium Retainers |

| Cylinder Head Modifications: | Port and Polish by Borkman |

| Head / Main Studs: | ARP Head Studs |

| Intake Manifold / Throttle Body: | FAT Custom intake manifolds w/ Dual Subaru Throttle Bodies |

| Air Induction System: | FAT Custom Induction |

| Fuel Injectors: | Denso 1,000cc/min Injectors (x4) |

| Fuel Delivery System: | Aeromotive A1000 Fuel Pump and filters, Adjustable FPR, Billet side feed rails, FAT Custom fuel lines |

| Engine Management System: | EcuTek Reflash |

| Engine Management Tuner: | Richard Garcia of Dyno-Comp |

| Boost Controller: | A’PEXi AVC Type-R |

| Spark Plugs: | NGK LFR7AIX Iridium IX Plugs (.028 gap) |

| Exhaust Manifold: | FAT Custom Exhaust Manifold |

| Exhaust System / Downpipe: | FAT Custom 3.5-inch Turbo-back |

| Wastegate: | TiAL Sport 44mm |

| Blow-Off Valve: | TiAL Sport Dual 50mm |

| Intercooler: | PWR Intercooler Core, FAT End Tanks |

| Cooling System: | Koyo Radiator |

| Oil System: | 08 STi Oil Pump, Moroso Deep Sump w/Baffled Aluminum Oil Pan |

| Fuel Cell: | FAT In-tank Pickup & Fuel Accumulator |

| Fuel Cell: | Aquamist Ver. 6 Water/meth Injection Aeromotive Profressive Fuel Pump Controller AEM UEGO wideband AFR |

| TURBOCHARGER | |

|---|---|

| Turbocharger: | Mercedes Benz AMG C32 Supercharger |

| Type: | Lysholm Twin-Screw Type |

| Manufacturer: | IHI |

| Compressor Wheel Specs: | 88mm Major, 63.5mm Inducer, 0.72 A/R |

| Turbine Wheel Specs: | 77mm, 78 Trim |

| Turbine Housing | 0.85 A/R |

| CHASSIS/DRIVELINE | |

|---|---|

| Springs, F&R (Make & Rate): | Turn In Concepts Springs (600 lbf/in, 800 lbf/in) |

| Shocks, F&R (Make & Rate): | KW Suspension V3 Dampers |

| Additional Suspension Components: | Whiteline End Links Cusco 22mm sway bars (F&R), Lateral Links, Trailing Arms, GTSPEC Camber Plates(F&R) |

| Transmission: | Motul Transmission Fluid Kartboy Shifter Bushings |

| Clutch / Flywheel: | Exedy Twin-plate Cerametallic Clutch |

| Axles / Driveshaft: | Drive Shaft Shop Level 5 Rear Axles |

| Wheels (Make, Size & Offset): | BBS 18×8.5-inch (F&R) |

| Tires (Make & Size): | NITTO NT05 245/40R18 (F&R) |

| Brake Rotors (Diameter, F&R): | Brembo Sport Slotted Rotors |

| Brake Pads (F&R): | Hawk Pads |

| Brake Lines: | Goodridge Stainless-steel Braided Lines |

| INTERIOR | |

|---|---|

| Roll Bar / Cage: | RPM Harness Bar |

| Harnesses: | Willans 4-point Harnesses |

| Gauges: | DEFI Oil & Fuel Press, Oil Temp & Boost |

| Etc.: | ATI Dash Pod, A-pillar 3 Gauge Pod |