Winning is everything to the competitor. They don’t care how it’s done, as long as it’s within the rules, it’s fair game. No boundaries, no limitations, just the necessary means to reach the top of the podium. In the case of racing, the vehicle and how it’s equipped according to the rules can make the difference between a podium spot or nothing. However, the ideal chassis doesn’t always come with the ideal engine. In order to win, picking the best of both worlds becomes essential.

Text by Richard Fong // Photos by Ginash George and Jake Rawson

FD Fanatic

Scott Sengpiel knows the Mazda RX7 well, having built one for street driving. What he loves most about the car is its perfectly balanced chassis. Like any Mazda enthusiast, he appreciated the two-rotor turbocharged 13B engine that equipped the RX7. But Sengpiel was also a realist, and knew from experience that the rotary engine was temperamental and required extra care for reliable performance. Soon after, practicality overtook purity, and he began looking at alternatives to the rotary engine.

Lust for the LS

Sengpiel’s search led him to the Chevrolet LS engine. While some might see it as sacrilegious, he looked at it from a practical standpoint. “Most will agree that the Mazda RX7 is one of the most balanced and well handling chassis available, and that’s what I love most about the FD3S. I researched alternative power plant options to the rotary, and all my research pointed toward the LS engine. It’s reliable, there is broad aftermarket support for the engine and it’s more affordable to maintain,” said Sengpiel. With the data backing his decision, he swapped an LS engine from a Camaro SS into his streetcar, and since then he’s been sold on the Chevrolet V8.

Race Case

In 2012, Sengpiel decided to build a second RX7, a dedicated racecar that would be a competitive endurance machine. Having competed in endurance races and the occasional NASA or SCCA time trial competition for approximately seven years, Sengpiel appreciated the challenge of not only building a great handling machine, but one that could endure long races too. His previous experience with the RX7 and the LS engine swap paved the way for his racecar build. He starting with the purchase of this 1994 Mazda RX7.

Fortifying the FD

Ever the planner, Sengpiel methodically tackled the build starting with the chassis. He stripped the FD down to the shell and began prepping for fabrication. Arc Asylum fabricated a 10-point NASA certified cage to reinforce the chassis in preparation for wheel-to-wheel racing. Braces welded into the engine bay further strengthened the shock towers and the chassis. Under the chassis, a Samberg subframe and transmission brace designed for an LS engine swap replaced factory pieces in preparation for the V8 transplant. The factory suspension arms make the connection to the subframe. The upper and lower control arms position the steering knuckles, which have been outfitted with Project Mu brake calipers, and 315mm vented and slotted two-piece rotors. Sengpiel fabricated a brake-cooling duct that channels airflow to the inside of the brake rotors. Volk Racing TE37 wheels wrapped with Nitto NT01 tires mount to the hubs, while a custom set of Öhlins track coilovers keeps the rubber pressed to the tarmac and suspend the chassis.

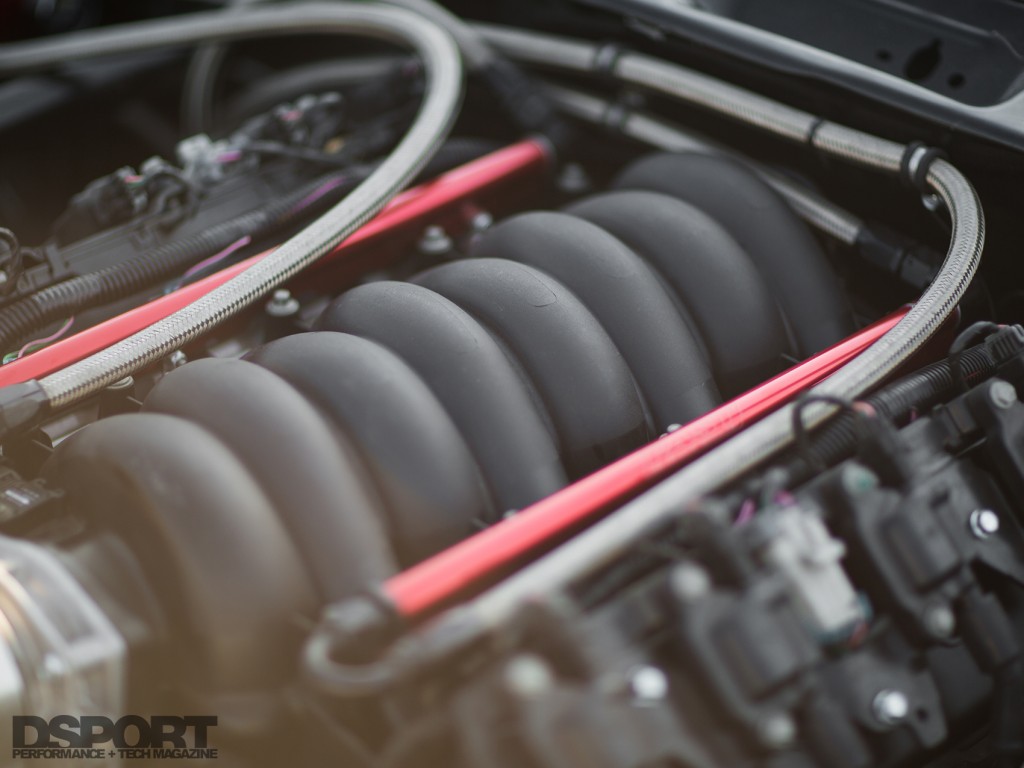

Heart of a Vette

Heart of a Vette

Once satisfied with the progress of the chassis build, Sengpiel shifted his attention to the heart of the racecar, an LS3 engine from a 2011 Corvette Grand Sport. When asked why he chose this particular block from the broad family of LS engines available, Sengpiel stated that the LS3 engine’s factory cylinder heads and intake manifold flowed well. In addition, this block also came standard with a factory dry sump oiling system. The 6.2-liter engine remained largely unchanged, save for the custom Comp road race ground camshafts, dual valve springs, hardened retainers and upgraded rocker trunions. A pair of Spoolin Performance Long Tube headers route the exhaust gasses into a custom Arc Asylum exhaust. Arc Asylum also fabricated the custom intake that feeds the intake manifold. With a light tune of the factory engine management system courtesy of West Bend Dyno, the LS3 spun the rollers of a Mustang Dynamometer to the tune of 445 horsepower and 409 lb-ft torque.

Dry Sump Trump

The LS3 fit well in the FD chassis, but it did suffer from some growing pains. During initial testing, the factory dry sump system appeared to be drawing in too much air, prompting the search for a solution to the critical oiling system. The ideal solution involved switching to a Dailey Engineering / Lingenfelter dry sump system, a Canton Racing sump pan and an aftermarket tank.

Eight to Turn Two

In order to convert 409 lb-ft of torque into forward motion on the track, Sengpiel bolted an ACT flywheel and twin-plate carbon race clutch to the crankshaft. The clutch transfers the torque to the input shaft of an MA Motorsports G-Force dog engagement transmission. The transmission spins a Driveshaft Shop propeller shaft linked to a Ford 8.8-inch differential carrier. Inside, an OS Giken Super Lock LSD splits the torque to the Driveshaft Shop Pro Level axles connected to the drive wheels.

Work In Progress

When Sengpiel mapped out this project, the plan was to start off in the NASA TT2 class and work his way up to TT1 and then the Unlimited class. However, some of the changes he made bumped his FD up to the TT1 class right from the start. He has a few more improvements to make before he goes to the track. Improvements to the front aero will help increase downforce over the front wheels to give the nose more bite at speed. Sengpiel also plans to redo the dash, seat position and the pedal setup to give him a more comfortable driver position behind the wheel.

Bad Ass or Blasphemous?

As the first race he plans to attend approaches, Sengpiel hopes to make a positive impact as one of the few LS swapped RX7s racing in the Midwest. He concluded, “The LS engine swap in the RX7 is a love/hate relationship in the community. I have massive respect for the rotary engine, but when it came down to a choice on building the car, the LS for me was just an all around better choice for what I wanted to accomplish. The LS requires less maintenance, there is better access to parts and upgrades and the cost to maintain is significantly lower. I hope that people can respect the build for what has been done and look past the fact that there is a V8 under the hood and not a rotary.” While this RX7 may not be everyone’s cup of tea, Sengpiel is keeping his eye focused on the competition and whatever it takes to win races.

SPEC SHEET

| VEHICLE | |

|---|---|

| Year / Make / Model: | 1994 Mazda RX7 |

| Chassis Code: | FD3S |

| Competition Class: | NASA TT1 |

| Vehicle Weight: | 2,700 lbs. (w/driver) |

| Weight Bias (F/R): | 50/50 |

| Shift RPM: | 6,800 RPM |

| Redline RPM: | 7,000 RPM |

| Fuel: | 93 octane |

| ENGINE | |

|---|---|

| Engine Code: | LS3 |

| Displacement (cc): | 6,162cc |

| Bore & Stroke (mm): | 103.25mm x 92mm |

| Peak Horsepower (@ RPM): | 444.5 whp @ 6,300 RPM |

| Peak Torque (@ RPM): | 408.8 lb-ft @ 4,200 RPM |

| Dyno Type: | Mustang Dynamometer |

| Engine Builder: | West Bend Dyno / Lingenfelter |

| Pistons/Compression Ratio: | 10.7:1 Compression |

| Camshafts: | Comp Cams Custom Road Race Grind |

| Valves / Springs / Retainers: | Comp Cams Dual Valve Springs & Retainers |

| Cylinder Head Mods: | Comp Cams Upgraded Rocker Trunions |

| Head/Main Studs: | ARP Head Studs |

| Air Induction System: | Arc Asylum Custom Intake |

| Fuel Delivery System: | Aeromotive A1000 External Fuel Pump |

| Engine Management System: | Factory |

| Engine Management Tuner: | Custom West Bend Dyno HP Tuners |

| Ignition System: | MSD Ignition Wires |

| Spark Plugs: | NGK Platinum |

| Exhaust Manifold: | Spoolin Performance Long Tube Race Headers |

| Exhaust System: | Arc Asylum Custom Exhaust |

| Cooling System: | C&R 3-inch Race Radiator |

| Oil System: | Dailey Engineering / Lingenfelter Dry Sump System |

| Fuel Cell: | Fuel Safe 22-gallon Endurance Cell |

| Performance Electronics: | Jordan Innovation Mil-spec Wiring |

| CHASSIS/DRIVELINE | |

| Springs, F&R (Make & Rate): | Öhlins Springs, 8kgf/mm, 9kgf/mm |

| Shocks, F&R (Make & Rate): | Öhlins custom track coilovers |

| Additional Suspension Components: | Custom Jordan Innovations track sway bar |

| Transmission: | MA Motorsports G-Force Dog Engagement |

| Transmission Gearing: | Custom |

| Final Drive: | 1.10:1 |

| Clutch / Flywheel: | ACT Twin Plate Carbon Race Clutch w/ Flywheel |

| Differential(s) (Make & Type): | Ford 8.8-inch |

| OS Giken Super Lock LSD | |

| Axles / Driveshaft: | Driveshaft Shop Pro Level Axles & Driveshaft |

| Wheels (Make, Size & Offset): | Volk Racing TE37, 18×10-inch, 18×12-inch |

| Tires (Make & Size): | Nitto NT01, 275/35R18, 315/30R18 |

| Brake Calipers (F&R): | Project Mu Calipers |

| Brake Rotors: | Project Mu Rotors, 315mm, 300mm |

| Brake Pads: | Project Mu Carbon Race Pads |

| Brake Lines: | Custom by Joe Lynch (@milwaukeesbest) |

| Roll Bar / Cage: | Arc Asylum NASA-spec 10-point Cage |

| Seats: | Sparco EVO2 Seat |

| Harnesses: | Sparco 6-point HANS-compatible Harnesses |

| Steering Wheel / Quick Release: | Sparco |

| Gauges: | Stack Cluster |

| Speed Hut Alt Gauges | |

| Etc: | Custom dash and Jordan Innovations control panel |

| EXTERIOR | |

| Front Bumper: | Shine Auto Feed Style |

| Front Lip Spoiler: | Custom On Point Motorsports |

| Front Fenders: | Shine Auto Feed Style +20mm |

| Hood, Trunk, Doors: | Seibon Carbon |

| Rear Fenders: | Pettit Motorsports Rear Overfenders |

| Spoiler / Wing, Mirrors: | APR Performance |

| Paint: | Black Magic Pearl |

| Custom Body Work: | JC Kustum |