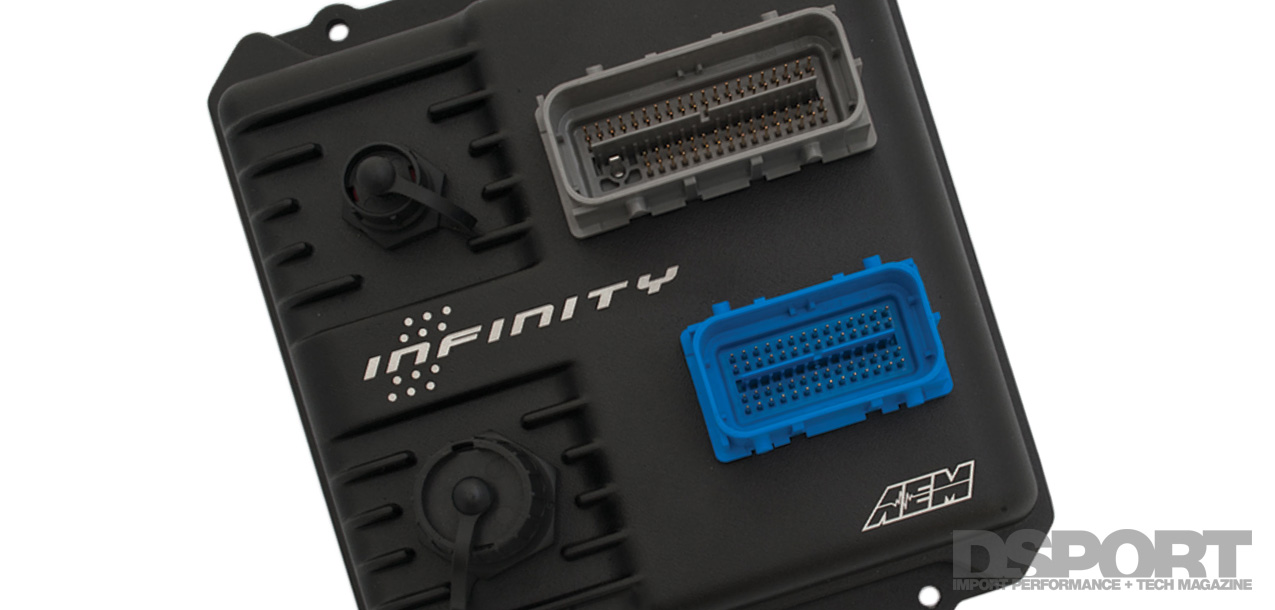

In this day and age of “there’s an app for that,” it is sometimes hard to “wow” someone with new technology. Instead of an “oh my God” reaction, a “that’s pretty cool” response is usually an indicator of something quite innovative. AEM Electronics is hoping for an “oh my God” reaction to its latest engine management system. The AEM Infinity-10 EMS puts leading-edge motorsports-technology engine management into a new platform for PnP high-performance enthusiasts.

Text by Michael Ferrara // Photos by Arnold Eugenio

The Legacy

While AEM may not have technically made the first plug-and-play (PnP) engine management systems, it was the first to produce a line of PnP engine management systems to gain mass appeal in the performance aftermarket. About four years ago, AEM launched the Series 2 version of its AEM EMS. The Series 2 line featured 12 injector drivers (up from 10), eight ignition drivers (up from five), four cam control and CAN protocol. Today, the original AEM EMS and Series 2 boxes hold the lion’s share of the stand-alone market in the States.

While AEM may not have technically made the first plug-and-play (PnP) engine management systems, it was the first to produce a line of PnP engine management systems to gain mass appeal in the performance aftermarket. About four years ago, AEM launched the Series 2 version of its AEM EMS. The Series 2 line featured 12 injector drivers (up from 10), eight ignition drivers (up from five), four cam control and CAN protocol. Today, the original AEM EMS and Series 2 boxes hold the lion’s share of the stand-alone market in the States.

[pullquote]FEATURES A TRUE 32-BIT PROCESSOR WORKING AT EIGHT TIMES THE SPEED OF THE (OLD) HYBRID-32/16-BIT PROCESSOR[/pullquote]While the Series 2 was a “minor” update for the AEM EMS line, the new Infinity-10 system is a completely new platform. This new chassis features a true 32-bit processor working at eight times the speed of the hybrid-32/16-bit processor used in the Series 1 and Series 2 boxes. The unit’s improved engine management performance is joined by a host of new features including flex-fuel support and ultra-fast datalogging.

Two Heads better than One

The AEM Infinity-10 EMS features a new architecture that relies upon both a main and secondary processor. The primary processor is a 200MHz, 32-bit workhorse with a built in math co-processor. This processor is able to process 400 MIPS (million instructions per second). Currently, the top OEM ECU processors operate at around 125 MIPS while the current generation of aftermarket ECUs generally operate around 50 MIPS. A secondary 20MHz, 16-bit processor is on hand to handle on-board power management and future peripheral expansion. Allowing the secondary processor to handle the less time-sensitive tasks frees the main processor to focus on the important stuff.

The AEM Infinity-10 EMS features a new architecture that relies upon both a main and secondary processor. The primary processor is a 200MHz, 32-bit workhorse with a built in math co-processor. This processor is able to process 400 MIPS (million instructions per second). Currently, the top OEM ECU processors operate at around 125 MIPS while the current generation of aftermarket ECUs generally operate around 50 MIPS. A secondary 20MHz, 16-bit processor is on hand to handle on-board power management and future peripheral expansion. Allowing the secondary processor to handle the less time-sensitive tasks frees the main processor to focus on the important stuff.

The Specs

A dozen peak-and-hold injector drivers and 10 ignition drivers allow the AEM Infiniti-10 to provide multiple fuel injection strategies for engines up to 12 cylinders. Thanks to the ultra-fast, true-32-bit main processor, injector lag time can be set in units of one-tenth of a millisecond. What does that mean with respect to engine management? Essentially, the tuner has the ability to set the injector pulsewidth time to a finer resolution that allows for more consistent air-fuel ratios and the ability to control large capacity injectors on a small displacement engine.

As for ignition timing, the AEM Infinity-10 system claims to offer infinite crank tooth resolution limit. Hence, any OEM triggering system can be utilized or a custom multi-tooth wheel can provide crank or camshaft position information to the EMS. According to AEM, the processing code has been tested at 100,000 RPM. The end goal of this improved resolution is to eliminate “dancing” ignition timing at start up or during rapid acceleration.

As for ignition timing, the AEM Infinity-10 system claims to offer infinite crank tooth resolution limit. Hence, any OEM triggering system can be utilized or a custom multi-tooth wheel can provide crank or camshaft position information to the EMS. According to AEM, the processing code has been tested at 100,000 RPM. The end goal of this improved resolution is to eliminate “dancing” ignition timing at start up or during rapid acceleration.

The Features

[pullquote]ALL OF THIS DATA AND MORE CAN BE CAPTURED AT UP TO 200-TIMES PER SECOND[/pullquote]The AEM Infinity-10 EMS systems incorporate two on-board channels for Bosch wideband oxygen-sensor control. As a CAN-enabled system, individual cylinder lambda readings are also possible with the inclusion of one or more AEM 4-channel UEGO controllers. While these sensors provide the feedback to monitor and log the air-fuel ratios, dual knock sensing circuits in the AEM Infiniti-10 EMS are said to condition the knock sensor signals for precise measurement of knock. All of this data and more (up to 256 channels, in fact) can be captured at up to 200-times per second. A healthy 2GB of logging memory is included or up to 32GB of space is available with a FAT32-formatted USB memory stick.

Dual-Personality

With the ever-expanding popularity of E85, AEM decided to incorporate flex-fuel technology into the AEM Infinity-10 EMS. By adding a flex-fuel sensor, the Infiniti-10 EMS can make appropriate corrections to fuel delivery, ignition timing and boost maps to provide optimum performance, efficiency and reliability with blended fuels ranging in ethanol content from zero-to-100 percent.

With the ever-expanding popularity of E85, AEM decided to incorporate flex-fuel technology into the AEM Infinity-10 EMS. By adding a flex-fuel sensor, the Infiniti-10 EMS can make appropriate corrections to fuel delivery, ignition timing and boost maps to provide optimum performance, efficiency and reliability with blended fuels ranging in ethanol content from zero-to-100 percent.

No matter the fuel, the AEM Infiniti-10 EMS delivers integrated engine protection strategies based on airflow, fuel pressure, oil pressure, engine temperature, engine speed (RPM) or knock. These engine-saving strategies can prevent a small problem from becoming a catastrophic failure.