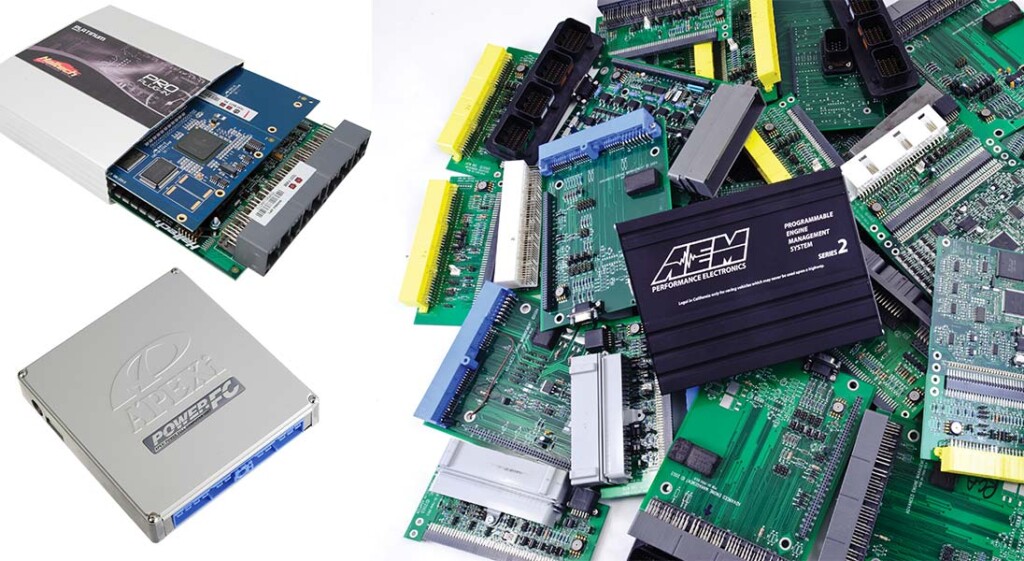

Twenty-five years ago, “chipping” an OEM ECU for high-performance or racing use left much to be desired. The “piggyback” came to the rescue for some, but others needed to “stand-alone” to unlock the potential of their performance combination. Early stand-alone solutions featured “flying lead” harnesses that required many hours of time to complete an installation. When the A’PEXi Integration Power FC and Series-I AEM Electronics ECUs hit the market, the plug-and-play application-specific stand-alone ECU was born. Today, “chipping” has been replaced by reflashing the OEM ECU. With the right reflashing interface and proper tuning, some OEM ECUs make a strong argument to stay in control. Piggybacks nearly became extinct, but some now offer a solution for those looking to safely run the factory calibration at higher boost levels without leaving any fingerprints in the process. The latest generation of stand-alone computers continue to make installations easier while delivering advanced features, additional inputs, additional controls, better OEM system integration and advanced datalogging. Ultimately, the decision on what’s best will come down to three factors: 1) What are the capabilities and limits of the OEM ECU? 2) What are your needs and desires with the engine/vehicle management system? 3) What are the costs of the solutions that can meet your needs?

Text by Michael Ferrara // Photos by DSPORT staff

DSPORT Issue #229

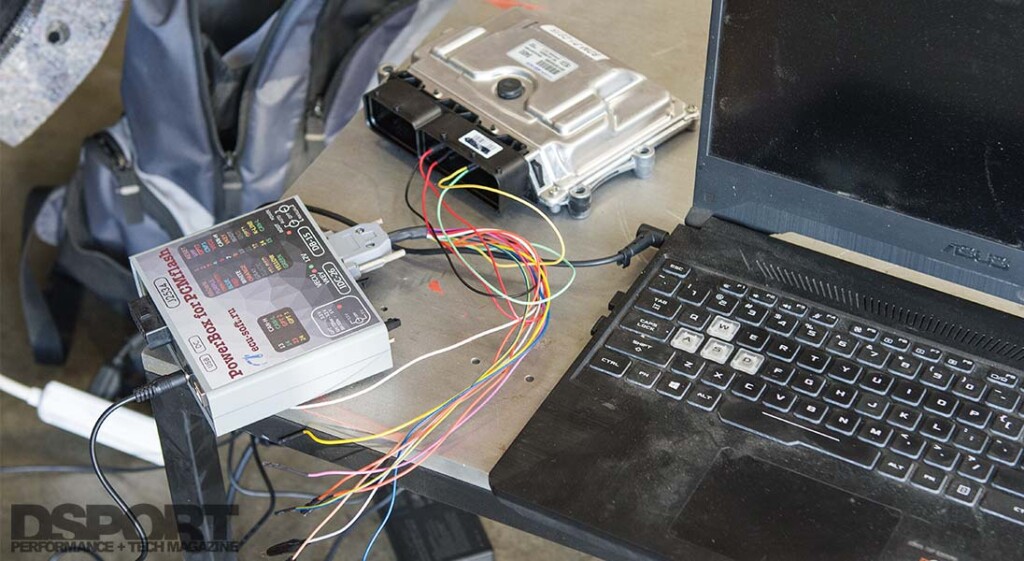

Companies like Hondata, EcuTek, COBB and HPTuners use an interface that gets teamed with software featuring application-specific models. This makes reflashing a very easy procedure.

OEM ECU Capabilities

The capabilities of your OEM ECU are tied into the level of technology present in the ECU. The ECU fitted in a car made in the last five years is far superior to the pre-OBD, OBD-I, OBD-II, and pre-CAN (before 2007). In the most basic terms, the newer the ECU in your vehicle, the less likely you will need to replace or augment it to meet your needs.

Being able to transform your OEM ECU that was designed for daily-driven duty into an ECU capable of proper engine management on your racecar will be dependent on two factors: the capabilities of the OEM ECU and the capabilities of the tuning platform used to reflash the OEM ECU. Hondata, Ecutek, Cobb, UpRev, HP Tuners, EFI Live and a host of other tuning platforms exist. Some are extremely well developed while others are rough around the edges.

Regardless of the tuning interface used, the OEM ECU can only do what it was doing before. If the OEM ECU was only in control of the engine, it is not going to be able to control the engine and transmission with a reflash. The OEM ECU is also only going to support the same inputs and outputs that it had originally. With the exception of a few cases, there are rarely extra inputs and outputs available on the OEM ECU. As a result, if you want to add a feature (i.e. flex fuel sensor input or fuel pressure sensor input), you generally have to lose one of the existing inputs. This may not be a problem on some applications, or it may be the reason why a different tuning solution is needed. On the R35 GT-R, racers using the factory ECU on their racecar have hijacked pressure sensors on one of the two banks of the engine to be able to feed the OEM ECU information from a fuel pressure sensor and/or flex fuel sensor. In this example, the ECU is reprogramed to just believe that the boost pressure feeding the left bank of the engine is identical to the right bank. While this works well in most cases, it can present problems when there is a significant boost pressure difference between the banks of the engines (ex. boost leak).

Regardless of the tuning interface used, the OEM ECU can only do what it was doing before. If the OEM ECU was only in control of the engine, it is not going to be able to control the engine and transmission with a reflash. The OEM ECU is also only going to support the same inputs and outputs that it had originally. With the exception of a few cases, there are rarely extra inputs and outputs available on the OEM ECU. As a result, if you want to add a feature (i.e. flex fuel sensor input or fuel pressure sensor input), you generally have to lose one of the existing inputs. This may not be a problem on some applications, or it may be the reason why a different tuning solution is needed. On the R35 GT-R, racers using the factory ECU on their racecar have hijacked pressure sensors on one of the two banks of the engine to be able to feed the OEM ECU information from a fuel pressure sensor and/or flex fuel sensor. In this example, the ECU is reprogramed to just believe that the boost pressure feeding the left bank of the engine is identical to the right bank. While this works well in most cases, it can present problems when there is a significant boost pressure difference between the banks of the engines (ex. boost leak).

Being able to perform the reflash through the OBD-II port is the ideal interface. Sometimes an ECU must be removed from a vehicle to be bench flashed. Bench flashing can sometimes be done by connecting to the pins of the ECU and other times it requires opening up the ECU and attaching to specific circuits on the printed circuit board. Bench flashing adds considerable time to the tuning process.

OEM ECU Interface

The majority of OEM ECUs that can be reflashed will be accessed through the OBD-II diagnostic port. Some of the newer ECUs will need to be “unlocked” or “jailbroken” before they can be reflashed. This process simply requires sending in the ECU or purchasing an unlocked ECU from the reflash provider. Some exotic and European cars may need to be “bench flashed.” Bench flashing requires that the ECU be removed from the vehicle opened up and manually reflashed. It becomes a real headache for tuners doing new calibrations.

While all the reflash platforms allow the ECU to be reflashed with the engine not running, a few offer live tuning. Live tuning allows temporary changes to be made to maps while the engine is running. These changes can later be saved and reflashed into the ECU when the tuning is completed. Live tuning decreases the time it takes to tune a setup.

Currently available for only the R35 GT-R, the COBB CAN Gateway add two analog or frequency sensors to the R35 CAN network. This allows the addition of a flex-fuel sensor and fuel pressure sensor without having to highjack any of the original sensor inputs.

Open the CAN Gates

While a factory ECU will have a set number of analog and frequency inputs, the factory ECUs that are also CAN based (most 2008 and up) essentially have an infinite number of inputs that can be received over the CAN network. The first aftermarket product to use additional CAN inputs with the reflash calibration is the COBB CAN Gateway. The COBB CAN Gateway can accept two additional analog (0-5v) signals or frequency signals and convert this to a CAN output that can be used by the factory ECU. The COBB CAN Gateway is currently available for the R35 GT-R. With the COBB CAN Gateway, a flex fuel sensor and a fuel pressure sensor send their signals to the COBB CAN Gateway which converts these to a CAN signal that the COBB tuned OEM ECU can use. As a result, no factory sensors are hijacked. While the COBB CAN Gateway represents the right way to add flex fuel and fuel pressure sensors to an R35 using the OEM ECU, it’s not as popular as it should be as this route costs a bit more, requires additional installation time and cannot be used with off-the-shelf maps. However, saving a few bucks, not spending enough time on the proper solutions, and not seeking out the right tuning are the reasons why people blow up their R35 engines. Hopefully, more racers will support this product and COBB will expand applications and capabilities for its CAN gateway in the future.

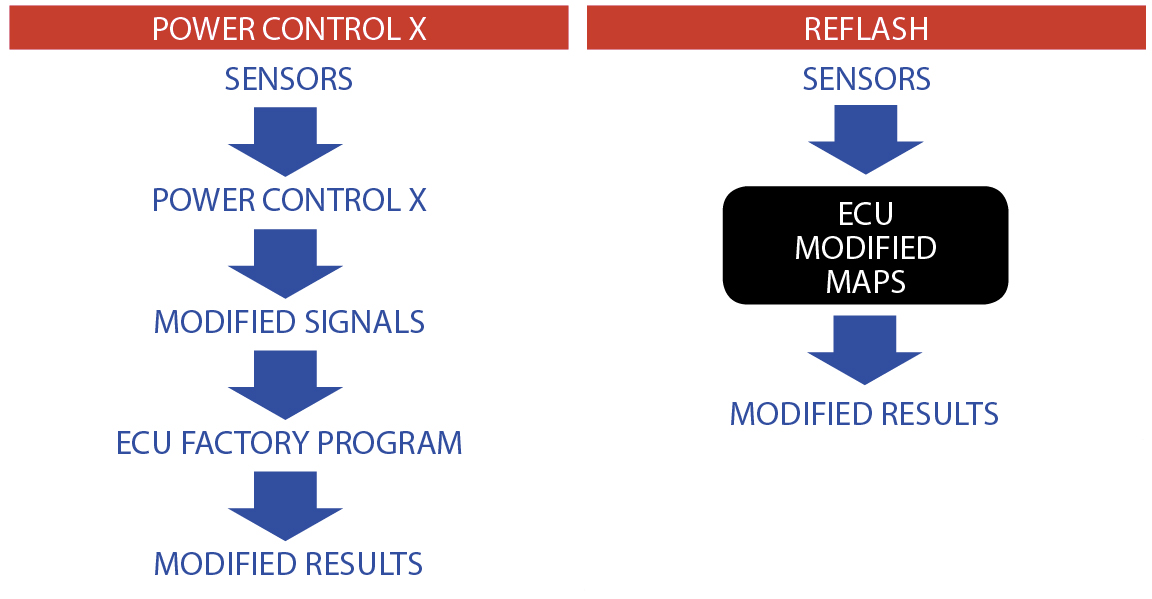

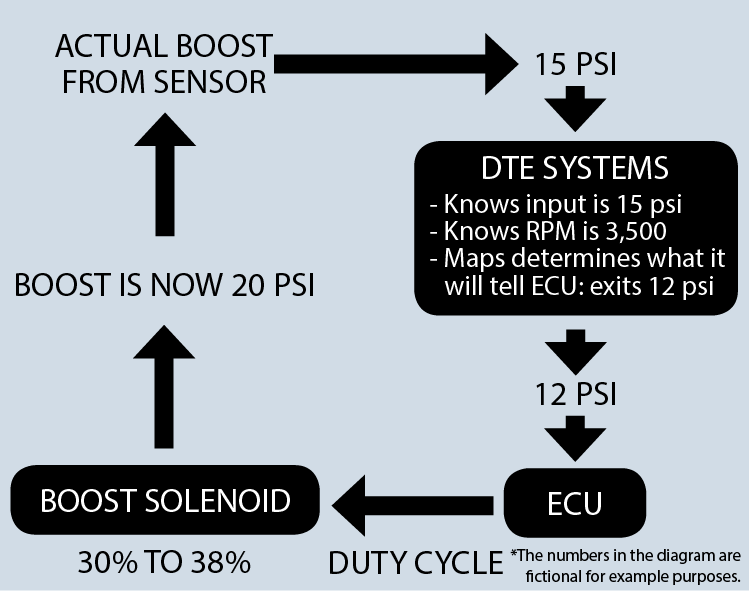

The DTE Systems Power Control X module is a piggyback controller that allows factory turbocharged vehicles to increase performance. Instead of changing the calibration in the ECU via a reflash, the Power Control X piggyback modifies the signals going into the factory ECU to increase performance. A/F ratios remain at factory targets while the boost can be increased to different levels to deliver peak performance based on the fuel octane rating.

A Piggyback Ride

There are a few scenarios that might warrant the need for a piggyback solution. In a piggyback solution, a sub computer is added to work with the OEM ECU. Sometimes the sole purpose of this piggyback computer or module is to modify or condition inputs from some of the sensors going into the ECU. In other applications, a piggyback solution might be used to run a set of additional port fuel injectors set up on a direct-port engine.

While a standard reflash modifies maps within the ECU, the Power Control X modifies the signals before entering the ECU. The conditioned signals lead the ECU to make some adjustments, like increase boost, that result in more horsepower and torque, without having access to the ECU settings or maps.

While there was a time when piggyback solutions were quite popular, the advent plug-and-play standalone solutions and better OEM ECUs/reflash platforms made all but a few disappear. Today, the major player in the piggyback market is DTE Systems. We tested the DTE systems Power Control modules on the Ecoboost Mustang, A90 Supra and our Kia Forte GT with solid results. The DTE Systems Power Control modules intercept and modify a number of the critical ECU inputs to increase boost pressure and deliver more power. The Power Control modules allow a few different settings so the boost level can be optimized for the octane ratings of the fuel being used. Even though boost levels are increased, air-fuel ratio levels remain unchanged. In addition, factory torque, power or boost limits can be avoided because the factory ECU is thinking it’s running within factory parameters when it’s running above these. While a DTE System Power Control module may change less than what is changed in a typical reflash, it does so without leaving any digital fingerprints in the process.

Piggyback units like the GReddy e-manage ultimate and the Split Second injector controller are proving to be relevant again due to the need to add additional injectors on some direct-injection applications.

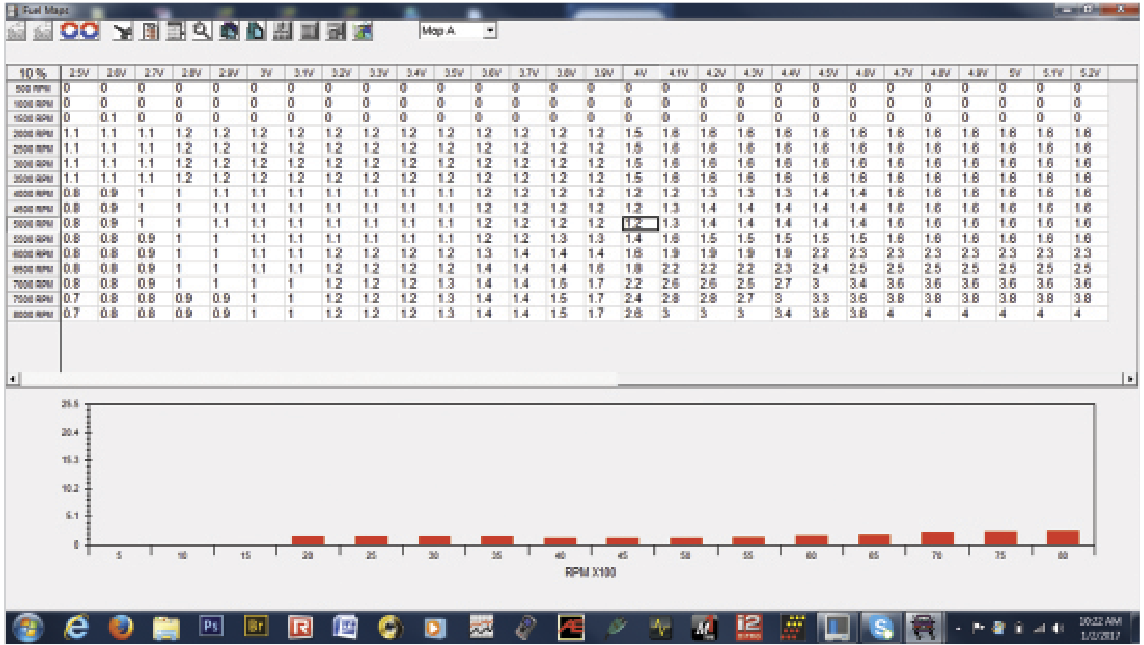

Plug-n-Play

As more and more factory engines turn to direct-injection for increased power output and efficiency, the aftermarket is still struggling to address additional fueling requirements on a number of the direct-injection platforms. As a result, the best solution for many exceeding the fuel flow potential of the OEM direct-injectors and direct-injection pump is to add a secondary port-fuel injection system to the engine to meet the additional fueling demands. For our Project Fiesta ST, this was the route we had to take to extract maximum performance from the upgraded turbo system. On its own, the Ecoboost 1.6L direct-injection system couldn’t deliver enough fuel and higher rate direct-injection injectors or direct-injection fuel pumps were not available. We asked Boomba to make us an intake manifold spacer plate that allowed us to add a port injector per cylinder and we put those under the control of a piggybacked injector controller from Split Second. While this controller is about as basic as it gets, it does allow a basic map to control fuel delivery based on engine speed and boost pressure.

We used a piggyback computer to control four additional port fuel injectors that we added to the ECOBOOST 1.6L engine in our Project Fiesta ST. Without this piggyback system, we were limited to the power capabilities of the OEM direct injection.

For those looking to design or implement an emissions-legal solution for a performance upgrade package, a piggyback controller may be part of the solution when the factory fuel system can not meet the fuel demands of additional power.

When plug-and-play stand-alone ECUs were coming to market with the A‘PEXi Power FC and AEM Series1, The M400, M600 and M800 ECUs from MoTeC were the top stand-alone available but they were not plug-and-play.

Stand-Alone

For some applications, a reflash of the OEM ECU or a piggyback module may not be enough to meet all that is desired from the tuner or driver. A full stand-alone solution may be the only solution that makes sense. The earlier the technology in the OEM ECU, the more likely a stand-alone solution will be required. While aftermarket stand-alone engine management systems have been around since the early 1990s, it wasn’t until plug-and-play stand-alone solutions became available that the popularity began to take off.

The A’PEXi Integration Power FC, short for Full Computer, was the first plug-n-play, aftermarket engine management system made available for Japanese performance vehicles. A’PEX Integration developed Power FCs for the most popular performance platforms in Japan. To reduce a potential downpour of tech support, A’PEXi Integration took a two-prong approach. First, they decided to provide an extremely fine-tuned base map. The base mapping provided with the Power FC actually underwent four-season testing to provide an OEM-quality tune that worked in the harsh cold of winter, the extreme heat of summer and everything in between. In addition, the FC Commander allowed for end users and beginning tuners to select different air flow meters and injectors in the calibration. We ran our Project RH8 R33-GT-R on Power FC until the release of the AEM Infinity ECU. By using FC Datalogit and getting a host of creative solutions in play, we were able to realize over 1,100whp running on the Power FC. While there are much faster, more powerful and more feature-packed aftermarket ECUs now available on the market, the A’PEXi Power FC still delivers exceptional results when asked to do what it was intended to do. Of course, those seeking features such as closed-loop lambda feedback fuel control, advanced boost control, flex fuel tuning, two-step rev limiter and antilag will need to find a different solution.

Realizing the importance of the plug-and-play market, MoTeC now offers plug-and-play versions of its top of the line M1 series ECUs for a number of applications. A conversion box and jumper harness is included in the system.

Today, stand-alone solutions take a number of forms. While the Power FC and original series 1 and series 2 plug-and-plag ECUs from AEM Electronics completely replaced the factory ECU in whole, solutions like the LINK G4+ maintain the factory ECU enclosure while replacing all of the electronics inside. Some other plug-and-play solutions from Haltech and MoTeC use adapter boxes and dramatically reduce installation time. While advanced users may opt for using a custom-built harness with a host of additional sensors, the larger plug-and-play audience will always choose convenience over a custom engineered solution.

As for integration with the CAN systems on newer vehicles, some stand-alone platforms can be set up to integrate seamlessly with all the factory-based CAN systems. In some cases, custom firmware can be designed to configure the stand-alone computer to do just about everything except your laundry.

Some plug-and-play stand-alone engine management solutions, like the Link G4+, are made to fit within the factory ECU enclosure.

Your Needs and Desires

Some just need an engine management solution that runs the engine in a decent state of tune. Maybe it’s to handle larger injectors, a different MAP sensor and a turbo upgrade that adds an extra 150 horsepower. Others may want more features. Two-step rev limiters, anti-lag, Flex fuel compatibility, advanced boost controls and traction control were once “nice to have” features that are now becoming essential items on many users’ lists. Adding a host of sensors that the ECU can use to provide an additional level of safety and performance will also influence the ultimate tuning platform for the application. The bottom line is that it is always better to spend more now to step into a system that does more than you need versus getting a budget system that doesn’t even meet all of your current needs.

Some just need an engine management solution that runs the engine in a decent state of tune. Maybe it’s to handle larger injectors, a different MAP sensor and a turbo upgrade that adds an extra 150 horsepower. Others may want more features. Two-step rev limiters, anti-lag, Flex fuel compatibility, advanced boost controls and traction control were once “nice to have” features that are now becoming essential items on many users’ lists. Adding a host of sensors that the ECU can use to provide an additional level of safety and performance will also influence the ultimate tuning platform for the application. The bottom line is that it is always better to spend more now to step into a system that does more than you need versus getting a budget system that doesn’t even meet all of your current needs.

The Bottom Line

Even though you and your best friend own the same vehicle platform, the “best” ECU solution for you may be vastly different than the best solution for your friend. Some people like to keep it simple and just want to enjoy the performance. Others may want to understand more of the how and why and look to extract every ounce of performance from the platform. Regardless of which tuning platform is selected, the capabilities of the person tuning the ECU will be more important than which ECU is in the vehicle. Unless you are using a performance combination that is sold as a package without any substituted parts, never rely on e-tuning. No matter the degree of talent with a tuner, expecting them to properly tune your vehicle without being in the driver’s seat for the dyno pulls is not realistic. You wouldn’t ask a surgeon to perform an operation blindfolded and wearing earmuffs, so don’t ask a tuner to do the same with your racecar. Do it right and you’ll do it once.