OUR SOLUTION

Our Chief Fabricator Lanny Higa worked closely with XRP in designing the E85 tank solution for our Project RH9 GT-R. To maximize the flow performance of the setup, our custom in-tank pump hanger and hat would utilize “bent tube” fittings exclusively to avoid the use of any 90-degree forged fittings. When you are flowing enough E85 to support 1,500 flywheel horsepower, each 90-degree forged fitting could add 1-to-2 psi of restriction when compared to a 90-degree bent-tube fitting. If your fuel system uses three forged fittings (one at the hat, one on the filter and one on the fuel rail), your pump would be working at a pressure that is 3-to-6 psi higher than it would need to with the bent tubing fitting in place. This means that your fuel pump will be delivering less fuel, drawing more electrical current and it will be closer to triggering the bypass valve. Whenever possible use bent tube fittings in place of those hard-90-degree forged fittings.

Our Chief Fabricator Lanny Higa worked closely with XRP in designing the E85 tank solution for our Project RH9 GT-R. To maximize the flow performance of the setup, our custom in-tank pump hanger and hat would utilize “bent tube” fittings exclusively to avoid the use of any 90-degree forged fittings. When you are flowing enough E85 to support 1,500 flywheel horsepower, each 90-degree forged fitting could add 1-to-2 psi of restriction when compared to a 90-degree bent-tube fitting. If your fuel system uses three forged fittings (one at the hat, one on the filter and one on the fuel rail), your pump would be working at a pressure that is 3-to-6 psi higher than it would need to with the bent tubing fitting in place. This means that your fuel pump will be delivering less fuel, drawing more electrical current and it will be closer to triggering the bypass valve. Whenever possible use bent tube fittings in place of those hard-90-degree forged fittings.

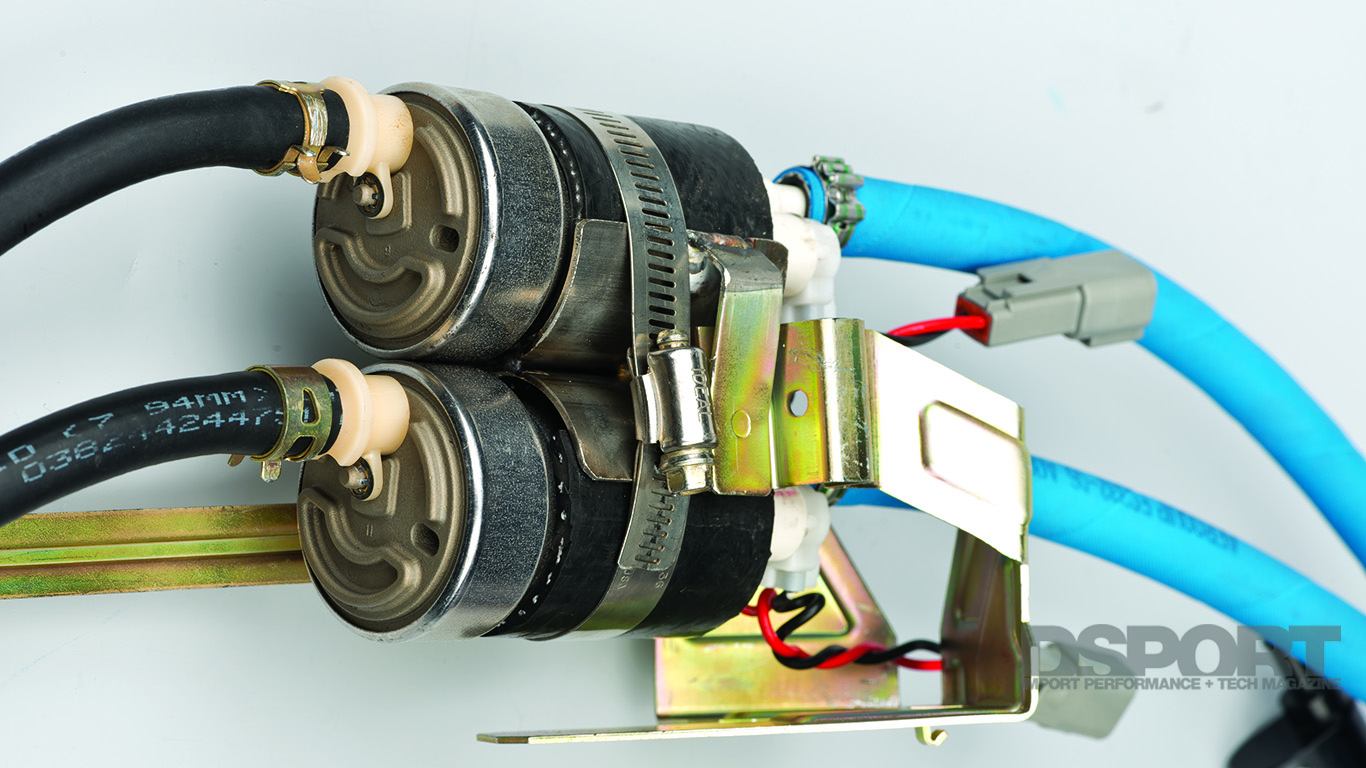

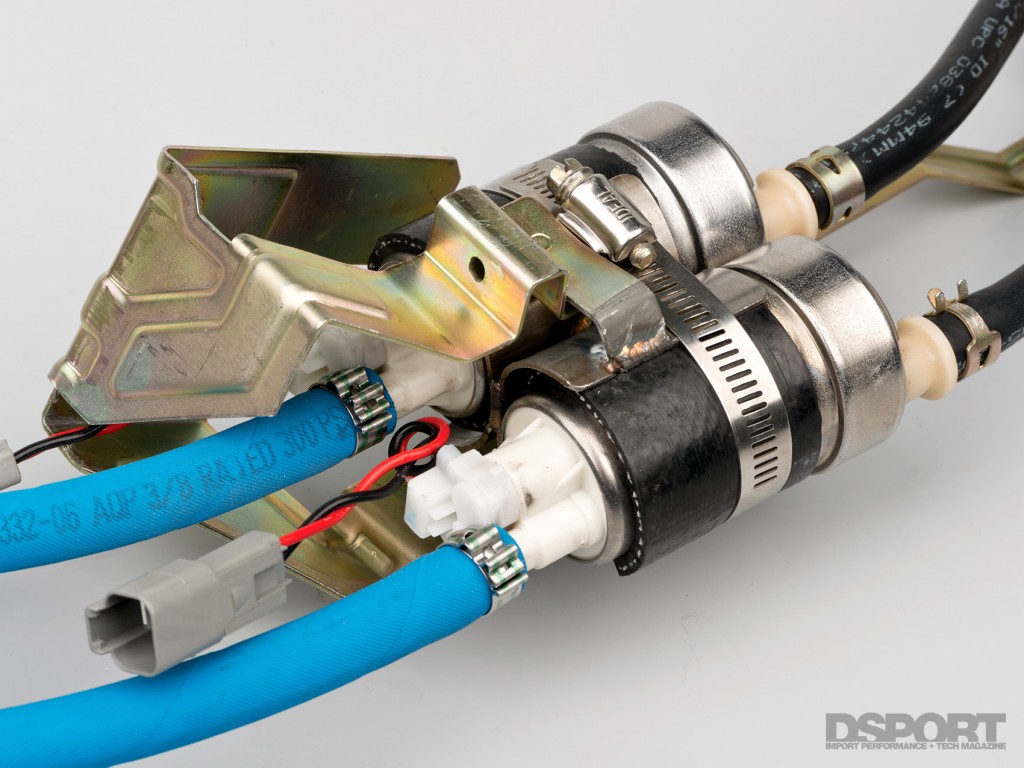

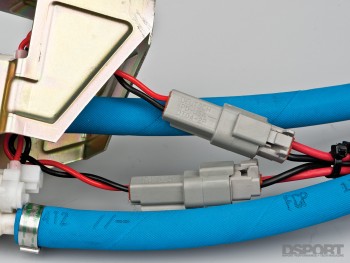

[pullquote]THESE SPECIAL CONNECTORS ENSURE THAT A PROPER ELECTRICAL CONNECTION IS MADE WITHOUT ANY FUEL VAPOR ESCAPING THROUGH THE SENSOR[/pullquote]To accommodate the bent-tube 90-degree fittings, Lanny designed the hat to use straight bulkhead -6AN fittings. These fitting required that the hat locate these fittings lower to accommodate the 90-degree bent tube fitting hose end. The hat itself was simple to make on the lathe. A total of three -6AN bulkhead fittings were used for the dual feeds and single return line. Another -4AN bulkhead fitting was used for the crossover vacuum feed that uses a “jet pump” to siphon fuel from the saddle portion of the fuel tank to the main pickup area.  XRP blue push-on hose and XRP Ensure clamps connected the pumps to the bulkheads on the bottom portion of the hat. A pair of hermetic mil-spec connectors (5-pin) were selected to carry the fuel pump power and ground signals as well as the fuel-level sending unit signal. These special connectors ensure that a proper electrical connection is made without any fuel vapor escaping through the connector. These connectors aren’t cheap and a special crimping tool is required to complete the connection.

XRP blue push-on hose and XRP Ensure clamps connected the pumps to the bulkheads on the bottom portion of the hat. A pair of hermetic mil-spec connectors (5-pin) were selected to carry the fuel pump power and ground signals as well as the fuel-level sending unit signal. These special connectors ensure that a proper electrical connection is made without any fuel vapor escaping through the connector. These connectors aren’t cheap and a special crimping tool is required to complete the connection.

THE RESULTS

So far, so good. The new system is functioning properly and fuel delivery is not an issue on our new E85 fuel. There are no fuel vapor smells from the vehicle and fuel delivery is meeting the demands during our initial testing. In our next installment, we’ll investigate the benefits of multi-stage filtering along with the control strategies for multi-pump applications. Stay tuned.