More power. We all want it and there is usually more than one way to get it. Serious solutions will involve a “power adder” in the form of a supercharger, turbocharger or nitrous-oxide injection system. These power adders can add anywhere from 30-to-300-percent more power. For those looking for big power solutions that don’t run out, we’ll focus on the forced-induction power adders, turbochargers and superchargers. Understanding the theory behind forced-induction and the differences between available forced-induction technologies should help you determine which forced-induction solution is best for you.

Text by Michael Ferrara

DSPORT Issue #227

(L) The compressor wheel spins, forcing more air into the intake manifold. Turbochargers don’t rob engine power, as they get their energy from wasted exhaust gases. (R) The turbine wheel and the compressor wheel are attached together using a shaft. Exhaust gases drive the turbine wheel, which in turn drives the compressor wheel.

The Turbocharger

Nearly-all turbochargers used for automotive applications feature the same fixed-geometry turbine design. This design incorporates a nozzle in the turbine housing of a fixed size that helps to establish the velocity of the flow of exhaust to the turbine wheel. In effect, it works in a similar fashion to the pulleys that are of a fixed ratio on a supercharger to determine its compressor speeds.

If there was even one replacement for displacement that V8 owners fear most it would be the turbocharger. Essentially two machines in one, a turbocharger is both a compressor and a turbine. Like a supercharger, a turbo has a compressor element. Rather than drive the compressor with a belt, a turbo drives the compressor with its second component the turbine. What’s a turbine? Long before steam engines, people harnessed Mother Nature’s energy resources to help do the work. By placing a paddle wheel in a flowing river, the wheel could be used to spin a shaft coupled to other mechanisms to mill grain. A turbine wheel works in the same way as a paddle wheel. In fact, think of a turbine as a paddle wheel for hot gasses instead of a flowing river. Instead of flowing water, a turbine uses the hot exhaust gasses that flow out of your engine on the exhaust stroke. The hot gasses are channeled through the turbine housing that speeds up the flow, acting like a nozzle shooting the flow of gasses against blades of the turbine wheel. This causes the turbine wheel shaft to spin. Since the same shaft mounts the turbine and compressor wheels, the compressor wheel spins at the same speed on the compressor side. Rather than relying on pulleys that control the speed of the compressor, modern turbocharger systems use a wastegate to regulate boost pressure. The wastegate reads the boost pressure at the intake manifold and opens its valve to maintain boost at a constant level. The valve channels exhaust flow away from the turbine wheel to regulate the shaft and compressor speeds.

How does a turbocharger’s boost response curve compare to a positive displacement and centrifugal supercharger? A turbocharger’s boost curve falls somewhere in between the two. The sizing of the turbocharger has a dramatic effect on how early or late in the powerband the turbo reaches its peak boost level. Once the engine reaches the RPM where the turbocharger produces peak boost, the boost curve generally performs like a positive-displacement supercharger keeping boost constant until redline. The exception to this occurs if the turbocharger goes beyond the horsepower capacity of the compressor section. In those cases, power will begin to drop off before redline. As for efficiency, the compressor efficiencies on most turbos edge out both centrifugal and positive-displacement superchargers. Easy to team with an intercooler, “intercooled boost” provides the ultimate in performance and reliability.

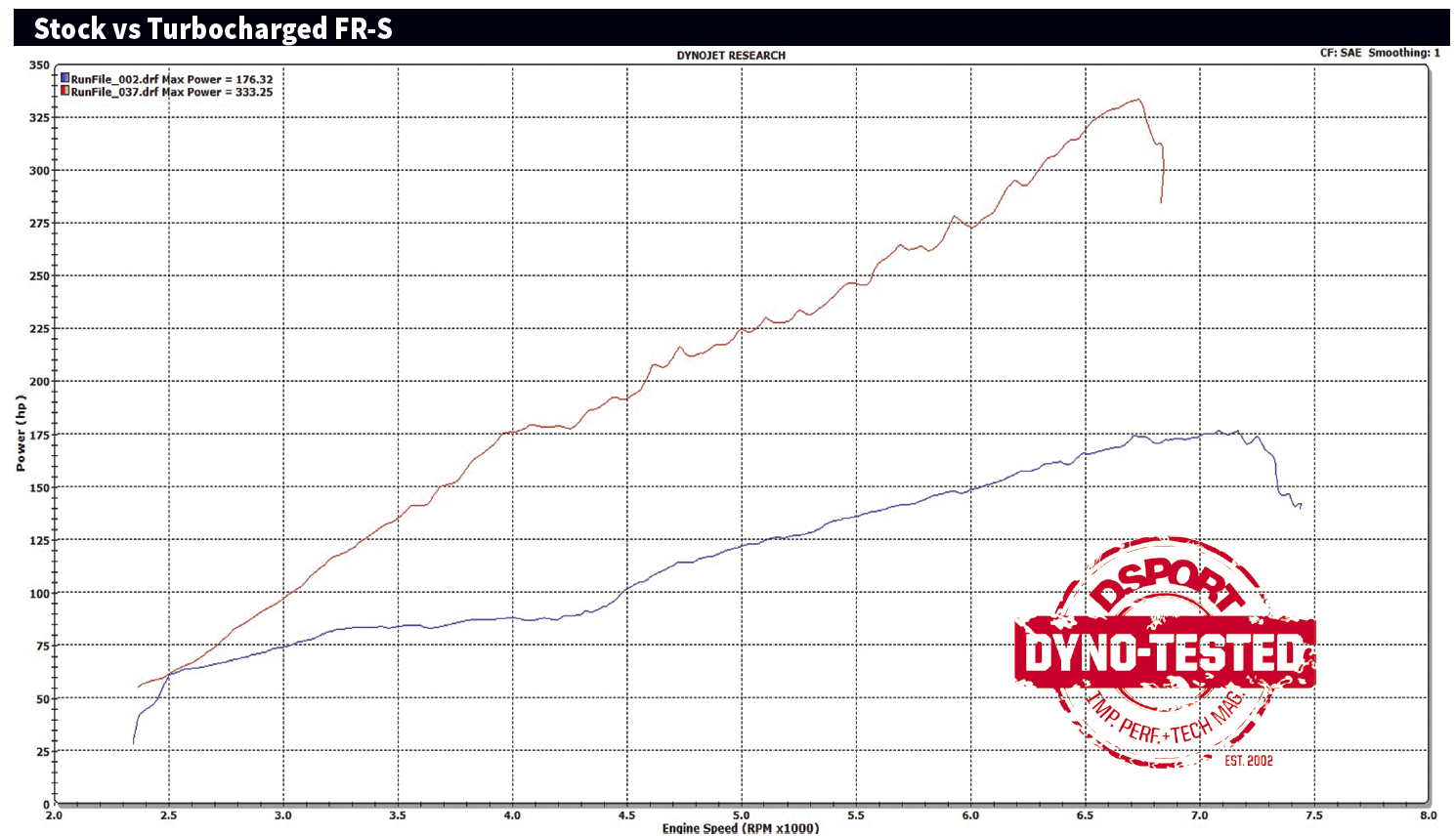

The bigger the turbocharger, the later on in the RPM range power will peak. Turbochargers completely changes the characteristics of the engine and its power delivery. In our turbocharged FR-S, final output was 333.25whp using a Full-Race kit and a BorgWarner EFR turbocharger. Later on we switched to E85, which increased the peak whp north of 550whp.

Centrifugal superchargers offer less boost response than positive displacement types, but it’s more efficient, drawing less crank power.

Centrifugal Supercharger

Originally introduced by McCullough (which is now Paxton), centrifugal supercharger systems are the most popular bolt-on-boost solution found on domestic performance vehicles. Today, Vortech, Kraftworks, and HKS offer centrifugal supercharger systems for imports. These centrifugal blowers have a substantially different boost and performance curve compared to a positive-displacement supercharger. Unlike positive-displacement units which provide the same airflow regardless of RPM, centrifugal units provide airflow proportional to the supercharger’s speed. The effect is usually characterized by not realizing peak boost until redline. If a centrifugal supercharger uses a pulley combination to generate four psi of boost at 4,000 RPM, it will produce eight psi of boost at 8,000 RPM (assuming the volumetric efficiency of the engine is the same at both engine speeds). Critics of centrifugal superchargers consider this gradual boost curve to be the biggest drawback or limitation of a centrifugal supercharger. On traction-limited cars, this isn’t necessarily a problem—in fact, it can be a solution to tire-spinning problems. In the real world, the gradual boost curve could translate into better hookup on traction-limited, front-wheel drive street applications. This may also result in better elapsed times. On a positive note, centrifugal superchargers benefit from high adiabatic efficiencies and are easier to be configured with an intercooler system for additional performance and increased reliability.

If you’re interested in building a custom supercharger system around a centrifugal supercharger, give the manufacturer a call to see which supercharger is needed to generate your target horsepower. Also, you need to let the supercharger manufacturer know which way the supercharger will spin when mounted on the engine since the rotation direction of a Honda D/B/H engine is unconventional (counter-clockwise).

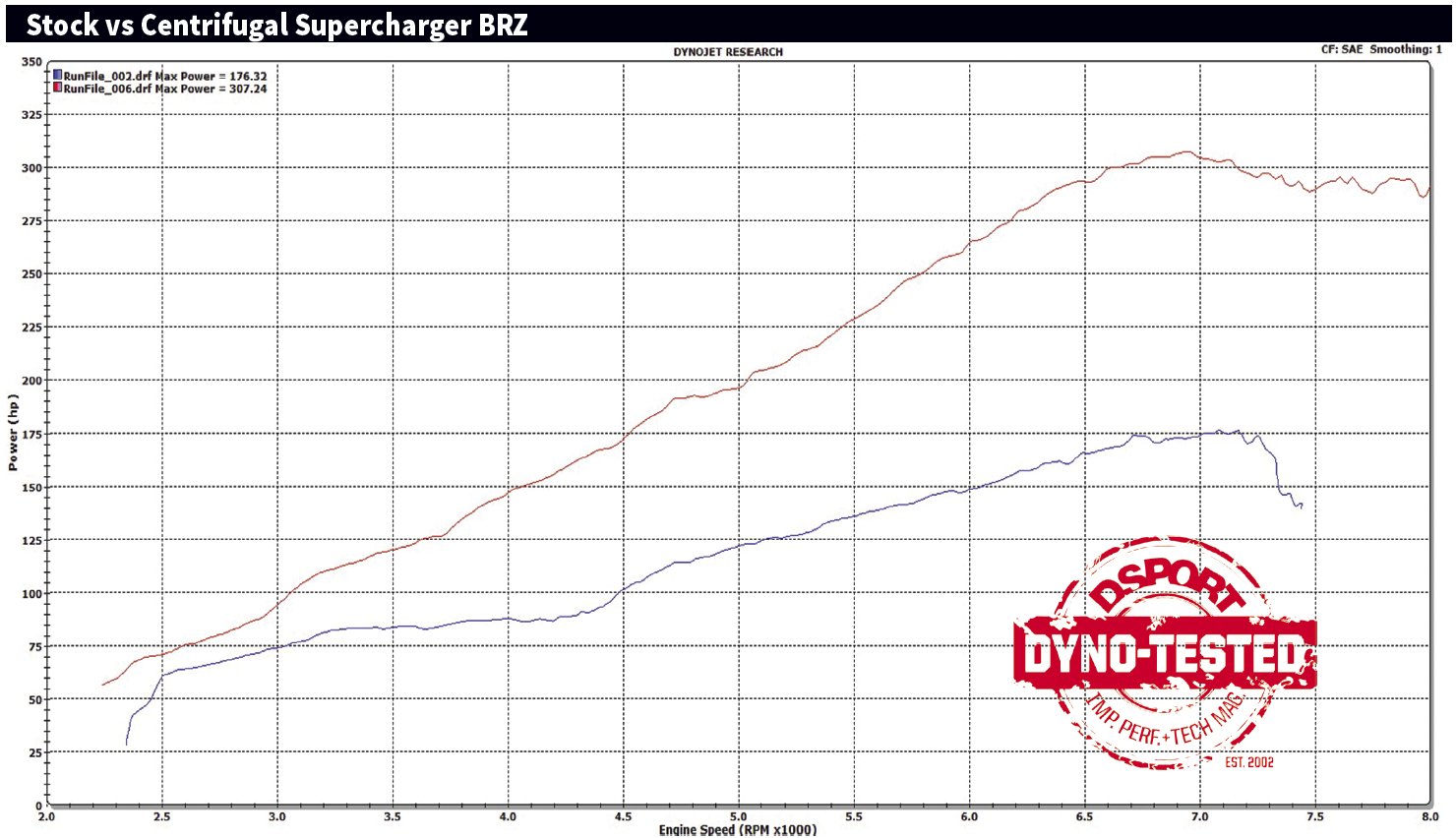

Our fully-built FA20 in the LA Sleeve BRZ project car utilized a Vortech V3 centrifugal supercharger. Chosen to protect the transmission and provide linear increase in performance, the result was 307.24whp from the stock 176.32whp. We also used a Vortech centrifugal supercharger on a stock BRZ with a conservative tune, and the result was 225.63whp.

Positive-Displacement Supercharger

Until about 25 years ago, all positive-displacement superchargers were a Roots-type design. Today, there are also a number of “screw” designs that fall under the positive-displacement classification. In either case, the more modern the design and manufacturing process of the supercharger, the better the efficiency of the unit. There are some Roots superchargers that exhibit very poor efficiency and some that function at very good efficiencies. The same can be said of screw-type superchargers.

No matter the design, all positive-displacement superchargers share a common characteristic. They pump out a fixed volume of air, regardless of the blower’s RPM. Many times this displacement of air becomes part of the supercharger’s name. For example, the Eaton M42 or Eaton M60 have a displacement of 40 and 62 cubic inches, respectively. The TVS1320 has a displacement of 1,320cc for every revolution of its compressor shaft. The result of this design is that boost response comes on in an instant.

With positive-displacement superchargers, the amount of boost pressure produced at the engine’s intake manifold is dependent on the blower’s displacement, the blower’s adiabatic efficiency, the displacement of the engine, the engine’s volumetric efficiency and the pulley ratio between the crankshaft and supercharger (also referred to as the percent of over-/under-drive). If someone upgrades to a larger displacement supercharger on the same engine with the same pulleys, the boost pressure generated will also increase. This results because the blower is pumping a greater volume of air than the engine can ingest, so the air not making its way into the engine is put under more pressure.

During our 86 Challenge, we equipped one of the cars with the Edelbrock positive displacement supercharger. The BRZ had a completely stock engine (as all other cars in the challenge), the result was 248.29whp and linear gains from start to redline. On a fully built FA20, we could get double this power or more using a positive displacement supercharger, but the engine internals wouldn’t have handled it on this vehicle.

The size of the engine also affects the boost level. As an engine’s size is increased, boost pressure will drop because a greater percentage of the air displaced by the blower can make its way into the larger engine. On positive-displacement blowers, boost can also be adjusted by varying pulley sizes on the engine and blower. In addition to the already mentioned factors, the breathing ability (volumetric efficiency) of the engine also affects the boost level. Engines with ported cylinder heads, healthy camshafts and aftermarket intakes will register a lower boost level than a stock engine. This is because the modified engine breathes as if it were a larger engine (from what we already know, a larger engine lowers the boost level). In general, positive-displacement superchargers are unmatched in the area of boost response. As for limitations, positive-displacement superchargers typically trail the adiabatic efficiency of centrifugal superchargers or turbocharger. As a result, charge air temperatures for a particular boost level on a given engine are typically higher than the same engine with a centrifugal supercharger.