Pumps and a Bump

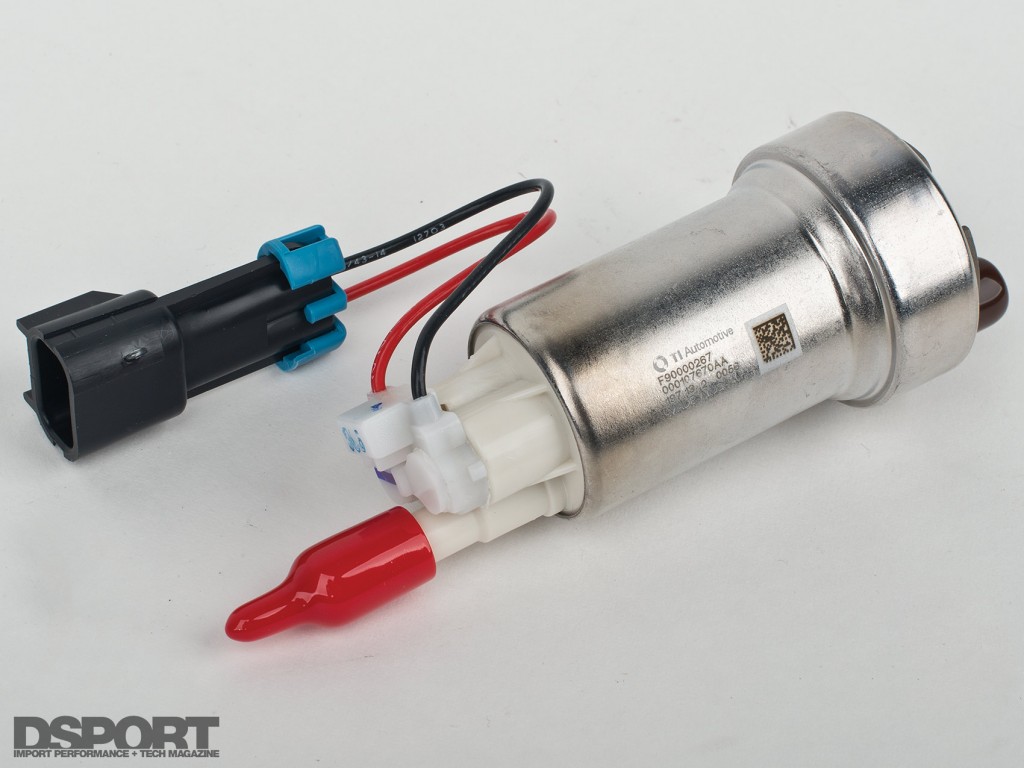

The job of the fuel pump in a fuel-injected system is to deliver pressurized fuel from the tank or cell to the injectors. Since fuel demand is directly proportional to horsepower, you must ensure the pump you choose can deliver enough fuel to support the amount of horsepower you want to make. Additionally, adjustments must be made to this target wheel horsepower level to account for the parasitic engine draw of the engine’s various crank-driven accessories.

The job of the fuel pump in a fuel-injected system is to deliver pressurized fuel from the tank or cell to the injectors. Since fuel demand is directly proportional to horsepower, you must ensure the pump you choose can deliver enough fuel to support the amount of horsepower you want to make. Additionally, adjustments must be made to this target wheel horsepower level to account for the parasitic engine draw of the engine’s various crank-driven accessories.

The Dynojet inertia chassis dynamometer is commonly used to measure wheel horsepower. Since these units over the least variance measured from location to location, the typically calibrated difference between wheel horsepower and flywheel horsepower is safely assumed to be 15%. Chart A shows how to calculate the total gross horsepower that your pump needs to support, based on the expected target wheel horsepower as measured on a Dynojet dyno. The calculations in Chart A reflect estimates based on gasoline as the fuel. Alternative fuels like methanol, ethanol and E85 blends have greater volumetric fuel demands than gasoline; generally, E85 and ethanol demands are 1.4-times and 1.5-times greater than gasoline.

The Dynojet inertia chassis dynamometer is commonly used to measure wheel horsepower. Since these units over the least variance measured from location to location, the typically calibrated difference between wheel horsepower and flywheel horsepower is safely assumed to be 15%. Chart A shows how to calculate the total gross horsepower that your pump needs to support, based on the expected target wheel horsepower as measured on a Dynojet dyno. The calculations in Chart A reflect estimates based on gasoline as the fuel. Alternative fuels like methanol, ethanol and E85 blends have greater volumetric fuel demands than gasoline; generally, E85 and ethanol demands are 1.4-times and 1.5-times greater than gasoline. Methanol makes twice the demand of the fuel system than gasoline. Be sure to include these factors when planning systems for these alternative-fuel-powered engines.

Methanol makes twice the demand of the fuel system than gasoline. Be sure to include these factors when planning systems for these alternative-fuel-powered engines.

Selecting a fuel pump that’s adequate for your system involves knowing the peak system pressure that will be encountered. Assuming properly-sized injectors will be utilized in your system, most tuners assume a base psi of 43.5 psi or 45 psi as the majority of available fuel injectors operate at one of these pressures. On forced-induction applications, the operating pressure will be higher as the fuel pressure regulator is designed to increase fuel pressure proportionally to boost pressure; the standard is 1 psi increase in fuel pressure for every 1 psi increase in boost. So, on a forced-induction engine that will run 30 psi of boost with the base fuel pressure set at 45 psi, the system should see a peak operating pressure of 75 psi.

pressure will be higher as the fuel pressure regulator is designed to increase fuel pressure proportionally to boost pressure; the standard is 1 psi increase in fuel pressure for every 1 psi increase in boost. So, on a forced-induction engine that will run 30 psi of boost with the base fuel pressure set at 45 psi, the system should see a peak operating pressure of 75 psi.

Finally, the voltage supplied to the fuel pump determines the pump’s output. Most alternator-equipped, 12-volt battery based vehicles will deliver 13.0 to 14.2 volts to the pump; this can be measured by using a voltmeter to measure the voltage “seen” at the pump. Where voltage is concerned, an increase in supplied voltage to the pump will result in an increase in the pump’s output. Be warned, this only holds true up to the normal voltage operating range of your pump. Further increases in supplied voltage could result in pump malfunction or failure. The operating voltage range is usually supplied by the manufacturer so check with them to see if your desired pump will handle the supply voltage that you feed it.

With the preceding information, you should be able to determine which fuel pump on the market will best suit your application. Some of the numbers and comparison charts may have to be supplied by the manufacturer; it’s always a good idea to seek out their advice on the pump that they produce and how it could fit into your fuel system.