Liquid Assets

When it comes to selecting liquid gaskets and sealers, DSPORT relies upon ThreeBond and OEM sealers. For liquid sealers to offer the best performance, proper preparation of the mating surfaces is critical. Improper prep, the use of the incorrect product or improper application can result in leaks and the accompanying headaches.

Prep School

A dirty sealing area can adversely affect the adhesive’s ability to bond with the surface. To ensure a good sealing surface, removal of the old gasket material and existing sealant material is highly recommended. While many silicone-based sealants can adhere to old gasket material and sealants, any area still containing old materials will be a possible point of seal failure. Once the old material is removed, the surface area should be checked for flatness. An uneven surface may not seal no matter how much sealant is used. Depending on the surface, there are various methods for flattening the surface if it has become warped. Once the surface is flat, a good solvent (brake cleaner or carburetor cleaner) can be used to remove the majority of contaminants from the product being assembled. However, some plastic housings can warp or melt if too strong of a chemical cleaner is used. Hence, it is better to stick to warm water and dish washing detergent to clean plastic housings. Unfortunately, most mechanics make the mistake of not taking the final step in prepping a surface for sealant. The final step is to remove the chemical residue left behind by the cleaning solvent. The sealing surface should be wiped down with an alcohol wipe or 90-percent isopropyl alcohol before applying sealant. Once the alcohol has evaporated from the sealing area, the surface is ready for a silicone-based sealant.

Eeny, Meeny, Miny, Moe

Choosing the right sealant can be difficult for even the most veteran mechanics. The first step to choosing the correct sealant for a job is evaluating the sealing surface. A sealant used for aluminum and steel may be different for plastic or rubber. Also the type of chemicals (oil, coolant, gasoline, etc.) that come in contact with the sealant will dictate which type is best to use. Some sealants might resist exposure to water and coolant, but not chemicals like oil and gasoline. Another factor in choosing the correct sealant is service temperature. Sealing an exhaust system requires an adhesive that can withstand extreme temperatures.

Choosing the right sealant can be difficult for even the most veteran mechanics. The first step to choosing the correct sealant for a job is evaluating the sealing surface. A sealant used for aluminum and steel may be different for plastic or rubber. Also the type of chemicals (oil, coolant, gasoline, etc.) that come in contact with the sealant will dictate which type is best to use. Some sealants might resist exposure to water and coolant, but not chemicals like oil and gasoline. Another factor in choosing the correct sealant is service temperature. Sealing an exhaust system requires an adhesive that can withstand extreme temperatures.

Easy Does It

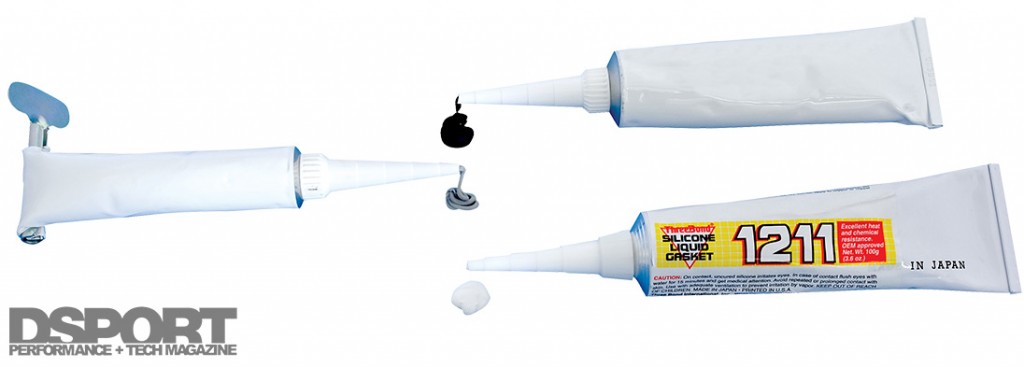

The number one mistake most mechanics make when applying sealant is using too much. Using an applicator tip or nozzle is a great way to neatly apply sealant without a mess. The thickness of the bead should be roughly the size of a spaghetti strand when assembling an oil pan. Applying too much sealant is not only wasteful, but can actually be harmful to the engine. The extra sealant can fall into the oiling or cooling system and clog crucial passages, leading to engine failure. After applying the sealant, it is time to reassemble the part.

Torqued

Always properly torque fasteners to manufacturers’ specifications. If the sealing area has more than three bolts, always use a criss-cross pattern to apply the load evenly. Most silicone-based sealants fully cure in 24 hours, but they can usually be exposed to fluids after 10 minutes.

Not Your Dad’s Sealants

Today’s automobiles are built to last over 100,000 miles. Keeping an engine leak free for that many miles requires the latest technology in sealants. ThreeBond International, one of the largest manufacturers of adhesive and sealant products in the world, works closely with the major car manufacturers to keep up with technology. Currently, ThreeBond high quality sealants are available from your local tuner shop.

ThreeBond RTV Gray (TB1200GAU) is formulated to be a heavy-body neutral-cure silicone. This RTV Gray is thicker than most silicone based sealants. This increased viscosity provides better blow- out resistance. The ThreeBond RTV Gray is also excellent for large-gap applications. ThreeBond RTV Gray has excellent adhesive properties, but it can still be easily removed even after curing.

ThreeBond RTV Black (TB1200BAU) is an ultra-tacky Formed-In-Place-Gasket (FIPG) that has a consistency similar to toothpaste. This family of sealant is often used to seal oil pans and camshaft housing. One advantage of ThreeBond RTV Black is its ability to seal contaminated surfaces.