Intake Manifold Design

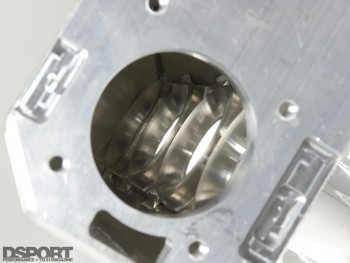

The designer of a performance intake manifold must take many factors into consideration. The cross-sectional area, length, taper angle and shape of the intake runners all have an impact on performance. Additionally, the shape and volume of the intake manifold’s plenum is also a major consideration. Larger-area runners will improve the flow at higher engine speeds, but may also slow the filling of the cylinders at lower engine speeds. Longer runners will sometimes impact the power and torque production at lower engine speeds while shorter runners may move the peak torque rpm higher up. Optimizing the shape and taper angle of the runners will allow maximum performance for a given runner length and area. The shape and size of the plenum should allow for proper pulse-reversion control and a good transition from the throttle body to the intake runners. A high-quality performance intake manifold should also have some type of air-horn machined into or cast into the transition from the runner to the plenum to improve the air flow path from the plenum to the runners.

Off the Shelf, Onto your Doorstep

Since most of us aren’t planning on building an intake manifold from scratch, we must depend on the high- performance intake manifold manufacturer to get it right. As we have already mentioned, just because a certain intake manifold looks bigger and better and bolts to the cylinder head doesn’t mean that it will offer improved performance. The same aftermarket intake manifold that optimizes performance on a near-stock engine may not be the ideal choice if engine displacement and redline have been increased. Speaking with the intake manifold manufacturer is always a good idea. Let them know about your engine combination, your intended use and your future performance improvements. They may be able to offer you valuable advice about what other components can be used to optimize your engine’s performance.

Out of the Box, Onto the Engine

Depending on the application, the installation of an aftermarket intake manifold can range from very easy to somewhat difficult. To ensure that the installation time is minimized and the performance increase is maximized, there are a few pre-installation steps that should be taken. First, read the installation instructions from beginning to end. It’s likely that you’ll find out that a special tool or special part is needed for the installation. If the aftermarket intake manifold doesn’t come with installation instructions, find out from the manufacturer what additional parts will be needed. Second, inspect the aftermarket intake manifold.

Depending on the application, the installation of an aftermarket intake manifold can range from very easy to somewhat difficult. To ensure that the installation time is minimized and the performance increase is maximized, there are a few pre-installation steps that should be taken. First, read the installation instructions from beginning to end. It’s likely that you’ll find out that a special tool or special part is needed for the installation. If the aftermarket intake manifold doesn’t come with installation instructions, find out from the manufacturer what additional parts will be needed. Second, inspect the aftermarket intake manifold.  During this inspection, see if there are any casting residues or defects present; inspect all threaded holes to check for breakthroughs or strip-outs. Complete any detail work that is needed before the manifold is installed. Third, match the throttle-body inlet to the throttle body gasket. Porting kits, like those available from Standard Abrasives, provide all of the tools, grinders, stones and paper rolls needed for a professional job. A can of machinist’s bluing and a scribe will allow you to trace the desired lines onto the flange. Fourth, check the relationship of the

During this inspection, see if there are any casting residues or defects present; inspect all threaded holes to check for breakthroughs or strip-outs. Complete any detail work that is needed before the manifold is installed. Third, match the throttle-body inlet to the throttle body gasket. Porting kits, like those available from Standard Abrasives, provide all of the tools, grinders, stones and paper rolls needed for a professional job. A can of machinist’s bluing and a scribe will allow you to trace the desired lines onto the flange. Fourth, check the relationship of the  intake manifold gasket to the cylinder head. Here, you need to see if the cylinder head’s ports match the gasket or are smaller than the gasket. If the cylinder head’s ports match the intake manifold gasket you can skip to the fifth step. If a phenolic or heat isolation gasket is available for your engine, now would be the time to install one. Cosworth thermal guard composite gaskets are already matched to Cosworth CNC ported heads. If the cylinder head’s ports are smaller than the gasket, you must compare this difference to the difference between the gasket and the ports on the intake manifold. The object is to make the intake manifold ports the same size as the cylinder head’s intake ports. If the cylinder head ports are larger than the gasket then the gasket must be modified to match the ports. Once this modification is done to the intake manifold gasket, the gasket can serve as a guide to match the ports on the intake manifold too. Fifth, thoroughly clean the intake manifold (inside and out) with soap and high-pressure water to remove any residue. After cleaning, use compressed air to blow out all remnant water before installation. Following this procedure will insure that you get maximum enjoyment from you aftermarket intake manifold.

intake manifold gasket to the cylinder head. Here, you need to see if the cylinder head’s ports match the gasket or are smaller than the gasket. If the cylinder head’s ports match the intake manifold gasket you can skip to the fifth step. If a phenolic or heat isolation gasket is available for your engine, now would be the time to install one. Cosworth thermal guard composite gaskets are already matched to Cosworth CNC ported heads. If the cylinder head’s ports are smaller than the gasket, you must compare this difference to the difference between the gasket and the ports on the intake manifold. The object is to make the intake manifold ports the same size as the cylinder head’s intake ports. If the cylinder head ports are larger than the gasket then the gasket must be modified to match the ports. Once this modification is done to the intake manifold gasket, the gasket can serve as a guide to match the ports on the intake manifold too. Fifth, thoroughly clean the intake manifold (inside and out) with soap and high-pressure water to remove any residue. After cleaning, use compressed air to blow out all remnant water before installation. Following this procedure will insure that you get maximum enjoyment from you aftermarket intake manifold.

The Bottom Line

We’ve have had the opportunity to use a number of aftermarket performance intake manifolds from a number of companies including Blox, Cosworth, Edelbrock, GReddy, Hypertune, Skunk2 and others. When matched to the proper engine, we’ve always seen substantial performance increases. Considering that a properly designed intake manifold also equalizes the cylinder-to-cylinder performance, the side benefits of smoother engine operation and improved reliability should not be overlooked. Remember, the intake manifold is the manager of airflow into your engine. Having the best manager available will ensure that your team of cylinders is working at its best.