Do you believe in miracles? What about a performance fuel that delivers race gas performance at a price below four-dollars per gallon? If you look at performance shops around the country, you’ll find more and more enthusiasts making the shuffle to E85. E85 is a blend of 85-percent ethanol and 15-percent gasoline that delivers racing gas performance at under four-dollars per gallon. While the popularity of E85 was previously restricted to regions offering widespread availability, the increasing support of FLEX fuel strategies by aftermarket engine management systems has made the E85 craze a national phenomenon.

While the performance potential and low cost of E85 puts it in a super-fuel class, failing to properly address the shortcomings of E85 will put the user in the stupid-fool class. An improperly-configured E85 conversion may not just affect performance; it may end up causing thousands of dollars in damage to your vehicle. Before you make the mistake of believing what the forums and blogs are promoting, it’s time you understand the reality. DSPORT will deliver the facts by outlining all critical factors in the E85 conversion process. In this first part, we will introduce our test vehicle, explain the factors that led us to decide that an E85/Flex Fuel-solution was right for us, showcase the major components needed in the conversion, and, finally, outline the details that need to be addressed at the tank.

Text & Photos by Michael Ferrara // Fabrication by Lanny Higa

DSPORT Issue #127

The Ultimate Test Bed

Our 1996 Nissan Skyline GT-R, a.k.a. Project RH-9 GT-R, has been with DSPORT since the start. Our original project vehicle has showcased the maximum performance potential of the stock-block RB26DETT engine while also becoming our first daily- driver capable of 9-second quarter- mile sprints in full street trim. After undergoing a recent restoration, this project is aiming for 8-second quarter-mile performance while maintaining its daily-driven, street- performance manners. A relatively small-displacement 2.8-liter engine will rely upon 38psi of boost pressure to generate over 1,200 horsepower to the wheels to reach its performance goals. Considering that the engine will be producing over 500-horsepower-per-liter at the flywheel, there will be little margin for error if anything isn’t done just right.

The Logic of E85

While we have had excellent results using VP Racing Fuels Q16 with our previous setup, there are some drawbacks to leaded racing fuel. First, the future availability of leaded racing fuels is always in contention. It may only be a matter of time before legislation passes regionally or nationally that restricts the use of leaded fuels even for off-road and motorsports use. Second, leaded fuels are only meant for off-road use. That means building a streetcar that can only achieve peak performance on leaded race gas means that you have to have a lower-performance “pump-gas” tune when you are on the street. Third, high performance fuels like C16, Q16 or VP Import are quite expensive.

Up until now, we’ve been reluctant to build DSPORT project vehicles to run on E85 due to the limited availability in Southern California. While the availability is probably not going to get better anytime soon, our Feature Editor Richard Fong is lucky enough to live close to a station offering E85 at the pump. However, this alone wasn’t enough to get us to make the switch. Instead, it was the ability to put together a performance flex-fuel solution that finally won us over. With the right parts in place, a proper flex fuel conversion will allow a vehicle to run on pump gas, E85 or any mixture of the two. Hence, we could get the maximum range per tankful when we decided to run pump gas. We could get the maximum performance when we filled the tank with E85. Or, we would get a blend of extended range and performance with any mixture of gasoline and E85 used. It appeared to be time to flex, if we could address all of the drawbacks of E85.

Evil85

While E85 offers great performance potential at a low price, there are evils associated with this fuel that must be recognized to safely exploit its benefits. The drawbacks of E85 are all results of the fuel’s reduced energy density, its varying quality, its higher flash point, its hydroscopic nature and its limited history of use in the United States.

While E85 offers great performance potential at a low price, there are evils associated with this fuel that must be recognized to safely exploit its benefits. The drawbacks of E85 are all results of the fuel’s reduced energy density, its varying quality, its higher flash point, its hydroscopic nature and its limited history of use in the United States.

The reduced energy density of E85 reduces vehicle range while increasing fuel supply demands. So how is range affected? Well, not as bad as you may think. Since pump gas is no longer 100-percent gasoline (it’s actually a blend of 10-percent ethanol with 90-percent gasoline, a.k.a. E10), it has an energy density of about 110,000 BTU per gallon of fuel. E85 has an energy density close to 82,000 BTU per gallon. This means that E85 has roughly 75-percent of the energy of E10. As a result, a vehicle’s range is reduced by 25- percent. If you only get 200 miles on a tankful of pump gas in your EVO XIII, you’ll only get 150 miles with E85 in the tank. As for increased fuel supply demands, E85 will require the fuel system to supply 35- percent more fuel for a given horsepower level. That means the pump(s), lines, regulator, injectors and return must all support 35- percent more volume at the same pressure as before.

E85’s varying quality (in terms of the actual percentage of ethanol content) can wreak havoc on E85 users that do not have an engine management system that is flex-fuel compatible. In these cases, the E85 dispensed at the pump may spec out to E85 on one fill-up and E65 on another fill-up (a common problem in areas with cold winters. In cases where a car is finely tuned to extract maximum performance from a true E85 blend, it may experience engine-damaging detonation when run on ethanol blends with a lower percentage of ethanol content (when the ECU is not able to adapt for the change in ethanol percentage).

One reason that E85 varies in its actual percentage of ethanol content is because some regions change to a winter blend that may be E70 or E65. The winter blend is used because the flash point (temperature at which liquid E85 begins to transition to a vapor or gaseous state) is about 55 degrees Fahrenheit. When the outside temperature falls below this, starting a vehicle on E85 becomes an extreme challenge. Blends with less ethanol, like E65 or E70, have lower flash points. Lower flash points allow better ignitability in low temperatures.

The final two evils of E85 are centered on its hydroscopic nature and its limited history of use. Due to its hydroscopic nature, E85 attracts moisture from the air. The end result is a buildup of water in the fuel system. This water can cause damage to injectors, pumps, lines and regulators, if not properly addressed. When storing E85, it’s important to avoid metal containers as the water can oxidize the interior and introduce rust into the fuel. As for keeping the fuel system in order, avoiding long storage period with E85 in the fuel tank is rule number one. From there, running pump gasoline (E10) every third or fourth tankful (on flex fuel equipped setups) should eliminate nearly all of the potential problems from E85’s hydroscopic nature. Pump gas’ higher gasoline content provides for improved lubrication of all moving parts within the fuel system, as well as superior upper cylinder lubrication of the engine itself.

Of course, not everything is known about all of the potential pitfalls associated with long-term usage of E85. Component compatibility and longevity with E85 use is still up in the air. While some components and materials may show no ill effects with E85 usage at room temperature, elevated temperatures with E85 may show problems on these same components and materials. In one case, this was evident on certain polymer fuel lines used in the engine compartment that were close to heat sources.

The SARD Jet-Pump Killer replaces the OE plastic jet pump with an aluminum unit. This ensures fuel is picked up from the saddle tank.

The Players: AEM, ID, WALBRO, XRP

So now you understand the ins and outs of an E85 or flex-fuel conversion. Ideally, street- performance vehicles should be configured for flex-fuel use. This allows all of the benefits of E85 while averting some of the drawbacks. A flex-fuel vehicle must have an engine management system and fuel system optimized to run both on gasoline and ethanol.

AEM Performance Electronics’ newest generation of engine management system, the Infinity EMS, has built-in flex-fuel support. Simply adding a GM flex-fuel sensor (about $450) to the fuel system provides the Infinity EMS with the ethanol content percentage of the fuel being used. With this data, the engine management system simply needs to be tuned in both a pure gasoline and an ethanol-blend (E85 or E98) configuration. Essentially, fuel and ignition maps for both extremes (pure gasoline and the highest- percent ethanol-content blend available) are made. The ECU can then use the information from the ethanol-content sensor to blend the tune accordingly.

As previously mentioned, an E85 fuel system must also be capable of supplying 35-percent more fuel than a system set up for gasoline. Previously, we were using RC Engineering 1,600 cc/min injectors. Factoring for 35-percent more fuel, we simply multiple the previous flow rating by 1.35 to get 2,160 cc/min as the desired flow rating. This number was right in line with the Injector Dynamics ID2000 injectors (2,225cc/min rating). Despite the massive flow ratings of these injectors, the saturated coil design allows for incredibly low duty cycles to be run. This allows these big injectors to provide exceptional idle. There is only one Achilles heel with the ID2000s and that is the injectors’ non-compatibility with fuels containing MTBE. The MTBE will damage the ID2000 and reduce their flow rating, so avoid fuels (like Q16) that contain MTBE if using these injectors.

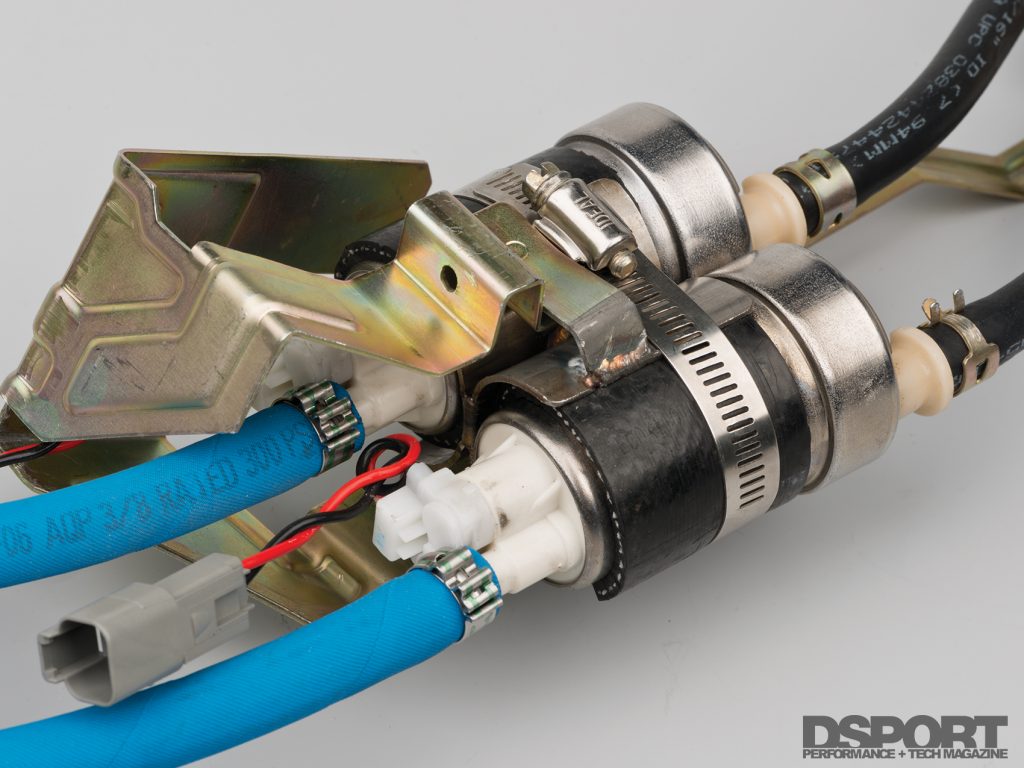

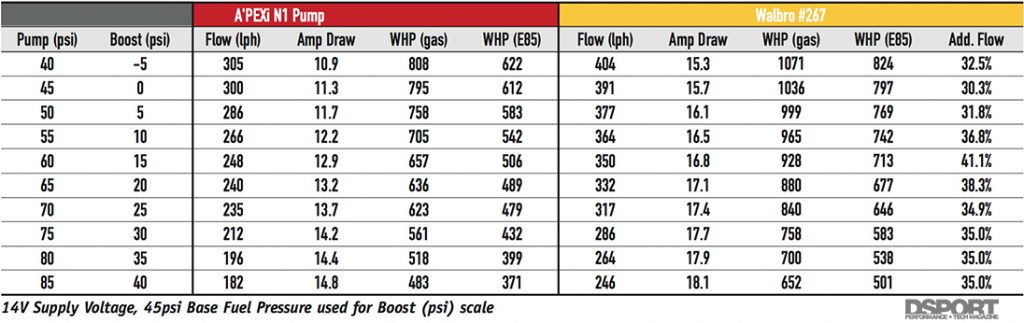

With the injection direction set, we needed to establish that the system was ready to pump it up. Walbro recently released its E85-compatible 400lph pump (p/n F90000267). In our testing, the pumps were able to deliver 250lph of flow at 80psi (the pressure the pump is working at when the boost pressure is at 37psi). Compared to the A’PEXi N1 pumps, the 267s deliver over 45-percent more flow, which is ideal for our conversion. Of course, this much additional flow requires a staged or pulse-width-modulated (PWM) solution to drive the fuel pumps. Simply running both pumps at a 100-percent duty cycle will exceed the limits of the regulator. As a result, the fuel pressure will exceed the desired base level. An overrun of fuel return will heat up the fuel too. We’ll address the solutions to these issues in part two of the E85 files.

One of the Walbro 400lph pumps will run all of the time while the second pump will be staged to come online at set loads and engine speeds

Finally, the fittings and lines must also be E85 compatible. We relied upon XRP, a leading producer of performance fittings and plumbing, to ensure that we had the proper performance fittings and fuel hose in the system. According to XRP, anodized aluminum performance fittings will have no issue with E85 assuming that no corners were cut in the anodizing process. As for the hoses, XRP suggests its professional-level HS-79 ultra-lite, flexible smoothbore PTFE (Teflon) hose assemblies for E85 applications. This is the same hose used by the majority of the Top Fuel and Funny Car teams. The HS-79 features a 4-ply or 5-ply construction (when ordered with the optional CSM fifth layer) which delivers superior flow rates, reduced pressure drop, tight bend radius, universal fluid compatibility and minimized weight. The PTFE inner tube is extremely chemically resistant to any type of fuel. Since it has a smoothbore construction, it doesn’t have the flow disturbances presented in convoluted hoses. The second, third and fourth plies of the HS- 79 hose work together to deliver superior strength and pressure capabilities without impacting flexibility. The silicone outer tube, stainless-steel wire braid reinforcement and aramid (Kevlar) layers use specific fiber and wire angles to maximize strength while maintaining maximum flexibility. The optional fifth layer (CSM) provides added abrasion resistance and an easy-to-clean surface. We employed this hose from the pump hat fittings forward to the fuel rail and back from the regulator to the tank.

In the tank, we used XRP’s push-on hose. This hose was chosen since XRP’s Ensure clamps can secure it to the barbed fittings coming out of the fuel pumps. This hose uses a three-ply construction consisting of a chlorinated polyethylene elastomer (CPE) inner tube, a reinforcing textile braid and a CPE outer construction. Since CPE is more permeable than PTFE, a “gas smell” can occur when this hose is used on a vehicle stored in a trailer or closed garage. While the level of permeation is not dangerous (unless fuel lines are run in the vehicle’s interior), it can be an odor nuisance. Since we are using the CPE-based hose in the tank, the permeation will have no effects. Because the XRP push-on hose has the same outer material as inner material, a visual inspection of the outer hose can be an indicator to the condition of the inner. At the temperatures seen in the fuel tank, we expect to see a long life from this CPE hose. However, we would not recommend this hose for E85 use outside of the tank. For those applications a PTFE inner core hose is a must.

In the tank, we used XRP’s push-on hose. This hose was chosen since XRP’s Ensure clamps can secure it to the barbed fittings coming out of the fuel pumps. This hose uses a three-ply construction consisting of a chlorinated polyethylene elastomer (CPE) inner tube, a reinforcing textile braid and a CPE outer construction. Since CPE is more permeable than PTFE, a “gas smell” can occur when this hose is used on a vehicle stored in a trailer or closed garage. While the level of permeation is not dangerous (unless fuel lines are run in the vehicle’s interior), it can be an odor nuisance. Since we are using the CPE-based hose in the tank, the permeation will have no effects. Because the XRP push-on hose has the same outer material as inner material, a visual inspection of the outer hose can be an indicator to the condition of the inner. At the temperatures seen in the fuel tank, we expect to see a long life from this CPE hose. However, we would not recommend this hose for E85 use outside of the tank. For those applications a PTFE inner core hose is a must.

Our Solution

Our Chief Fabricator Lanny Higa worked closely with XRP in designing the E85 tank solution for our Project RH9 GT-R. To maximize the flow performance of the setup, our custom in-tank pump hanger and hat would utilize “bent tube” fittings exclusively to avoid the use of any 90-degree forged fittings. When you are flowing enough E85 to support 1,500 flywheel horsepower, each 90-degree forged fitting could add 1-to-2 psi of restriction when compared to a 90-degree bent-tube fitting. If your fuel system uses three forged fittings (one at the hat, one on the filter and one on the fuel rail), your pump would be working at a pressure that is 3-to-6 psi higher than it would need to with the bent tubing fitting in place. This means that your fuel pump will be delivering less fuel, drawing more electrical current and it will be closer to triggering the bypass valve. Whenever possible use bent tube fittings in place of those hard-90-degree forged fittings.

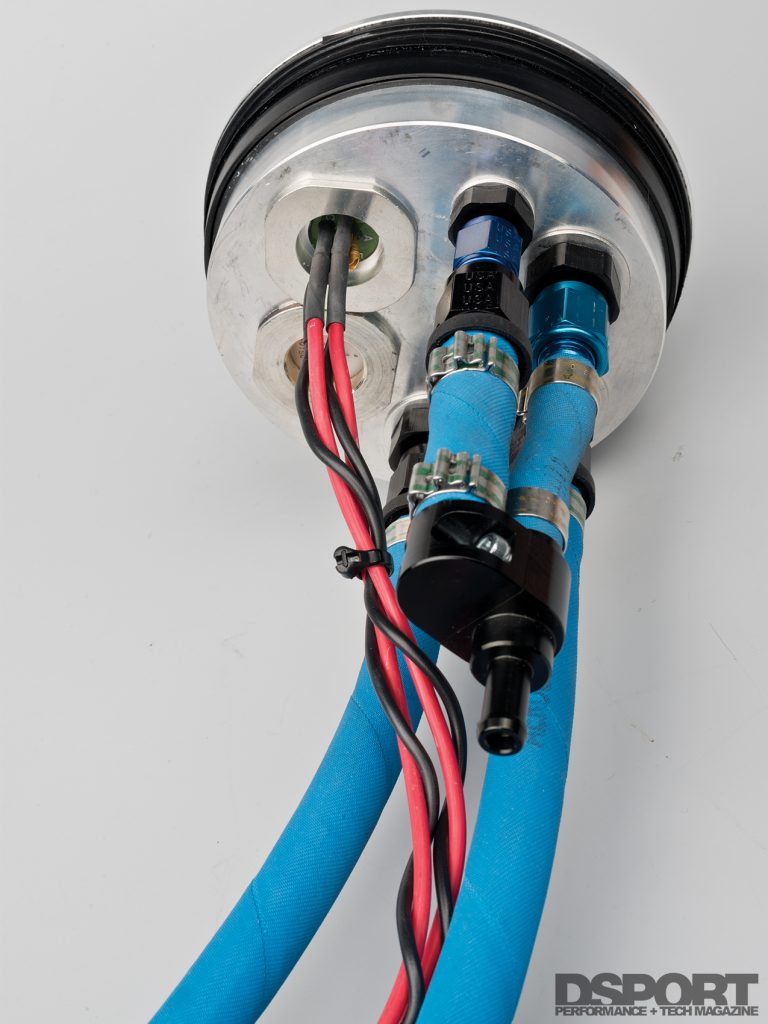

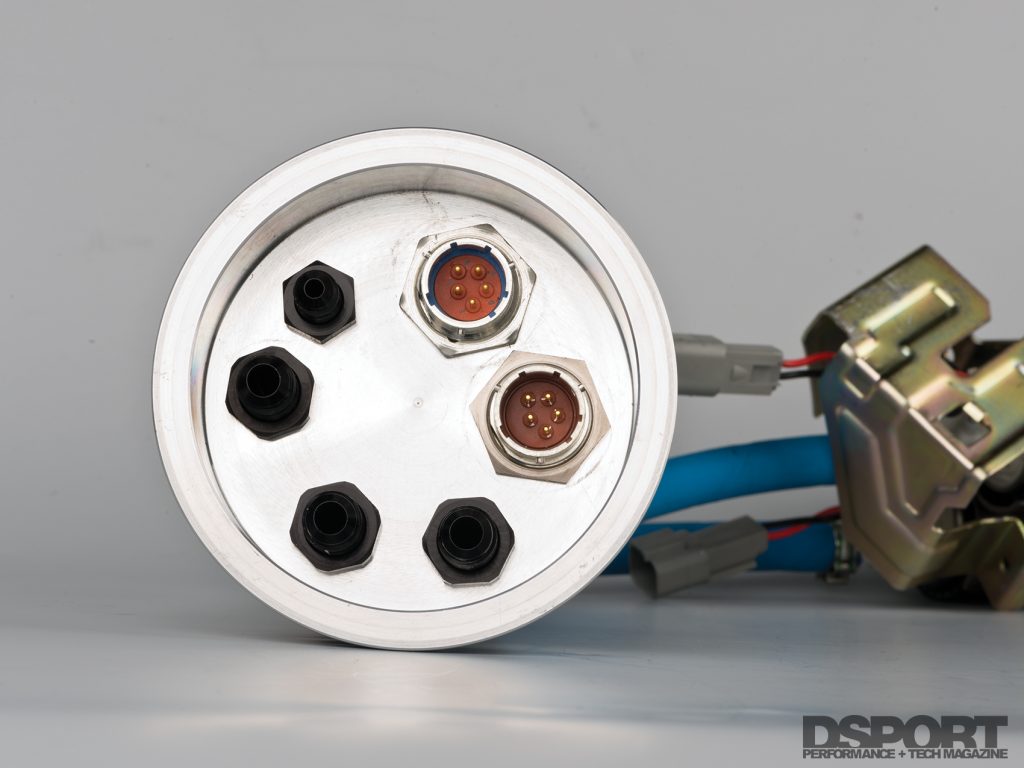

To accommodate the bent-tube 90-degree fittings, Lanny designed the hat to use straight bulkhead -6AN fittings. These fitting required that the hat locate these fittings lower to accommodate the 90-degree bent tube fitting hose end. The hat itself was simple to make on the lathe. A total of three -6AN bulkhead fittings were used for the dual feeds and single return line. Another -4AN bulkhead fitting was used for the crossover vacuum feed that uses a “jet pump” to siphon fuel from the saddle portion of the fuel tank to the main pickup area. XRP blue push-on hose and XRP Ensure clamps connected the pumps to the bulkheads on the bottom portion of the hat. A pair of hermetic mil-spec connectors (5-pin) were selected to carry the fuel pump power and ground signals as well as the fuel-level sending unit signal. These special connectors ensure that a proper electrical connection is made without any fuel vapor escaping through the connector. These connectors aren’t cheap and a special crimping tool is required to complete the connection.

The Walbro #267 pumps meet our needs to increase our fuel flow by 35 percent over the A’PEX N1 fuel pumps. Notice that they do require close to 20amps of current so be sure to use a properly rated relay, fuse and wiring.

The Results

So far, so good. The new system is functioning properly and fuel delivery is not an issue on our new E85 fuel. There are no fuel vapor smells from the vehicle and fuel delivery is meeting the demands during our initial testing. In our next installment, we’ll investigate the benefits of multi-stage filtering along with the control strategies for multi-pump applications. Stay tuned.