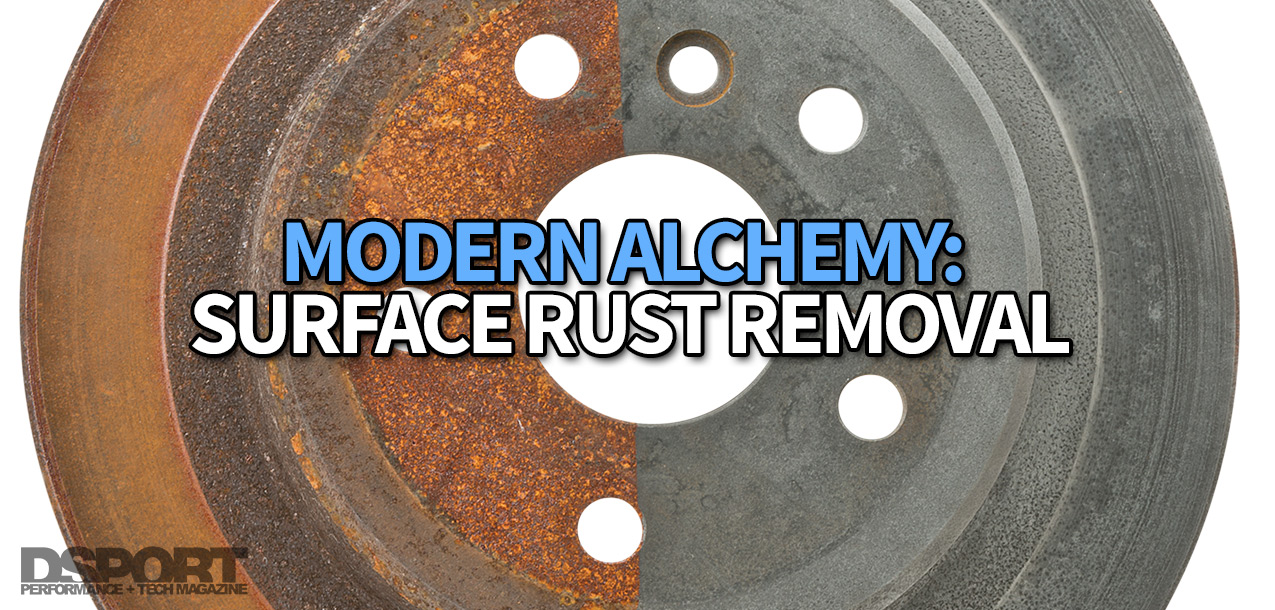

Rust. It’s ugly, it’s a sign of deterioration and it’s never a positive indication of the condition of parts. While hipsters are into the “patina” look, the rest of the population avoids rusty parts, especially since parts being prepared for fabrication or paint do not benefit from this layer of oxidation.

Rust is the oxidation of iron and its alloys, like steel. Deterioration and subsequent damage form when untreated or unprotected components are exposed to a combination of oxygen, air moisture and/or water. In snow country or areas of high salt content, the process of degredation occurs more rapidly because of the acidity of salts. While some alloys contain elements like chromium (stainless steel) to help resist the pitting and deterioration from oxidation, other alloys (like many found on automobiles) rely on paints or coatings for protection from the elements. Friction surfaces like brake rotors and flywheels expose raw metal and begin to oxidize quickly.

When exposed to the elements over extended periods of time, any raw or unprotected iron mass will eventually rust through completely and turn to iron oxide dust. But if caught early on, the oxidation can be stopped before the damage becomes irreparable.

Text by Richard Fong // Photos by Jun Chen and Richard Fong

DSPORT Issue #145

Rust, Be Gone

There are a number of methods for rust removal. From physically or mechanically removing rust (scrubbing, sanding or grinding) to chemically removing rust (from specialized chemical products to household consumables), removing surface rust can be accomplished in a variety of ways. Caution and prudence should be exercised at all times, since some of these methods result in toxic byproducts that must be dealt with carefully and consciously.

Manhandling Oxidation

The physical removal of rust by way of a wire brush, wire wheel or grinder is a quick method of exposing raw metal in preparation for painting or welding. While this method has its merits, it isn’t necessarily ideal for all applications. These mechanical solutions remove the surface rust with ease; however, some of the base material may be worn away in the process.

Liquidating Rust

An alternative to physically attacking rust involves liquids. Science has come quite a way, even when the objective is the simple task of removing rust. There are three types of chemical rust removal that we will evaluate, including non-toxic solutions, acid-based chemicals and home remedies. For each liquid, an equally rusted steel tube sample was immersed and treated. The samples were inspected in fifteen-minute intervals for the first hour, then once per hour for the following three hours in order to determine how quickly and effectively each liquid could eliminate rust. Then, the samples were left to soak for a 48-hour period to see if extended exposure to the chemicals had any positive or negative effect on the sample. In addition, we exposed aluminum, copper and brass samples to each liquid for a period of one hour to see if the chemicals offered any benefit or damage to these metals.

In each of the evaluations, the results and observations of the test, along with important data regarding each chemical are presented. Handling information, product contents and HMIS ratings are also included.

TIP Most rust removers do just that, remove rust. However, most do not offer any sort of protection from the return of rust. To protect against subsequent oxidation prior to being welded, painted or powder coated, be sure to apply some sort of protectant such as a light coat of oil, WD-40 or a similar product.

TIP Think safety. Regardless of the sort of chemicals you are using, toxic or not, should be handled with care and respect. Be sure that the containers you use (for submersion) are chemical resistant, perform the rust removal outdoors or in a well-ventilated location, and use proper protective equipment (chemical/acid proof gloves and goggles/face shield.) These are corners you should never cut.

Hazardous Materials Identification System: HMIS

The Hazardous Materials Identification System, HMIS, is a numerical hazard rating system developed by the American Coatings Association to comply with OSHA Hazard Communication requirements. The four categories (Health, Flammability, Physical Hazard and Personal Protection) are color coded Blue, Red, Orange and White, respectively. They are rated on a scale from 0-4 with 4 being the highest rating in each category.

Page 2: Non-Toxic Chemical Reactions

Page 3: Corrosives For Cleaning