Non-Toxic Chemical Reactions:

Chemists Design Eco-Friendly Rust Removers

Chemists Design Eco-Friendly Rust Removers

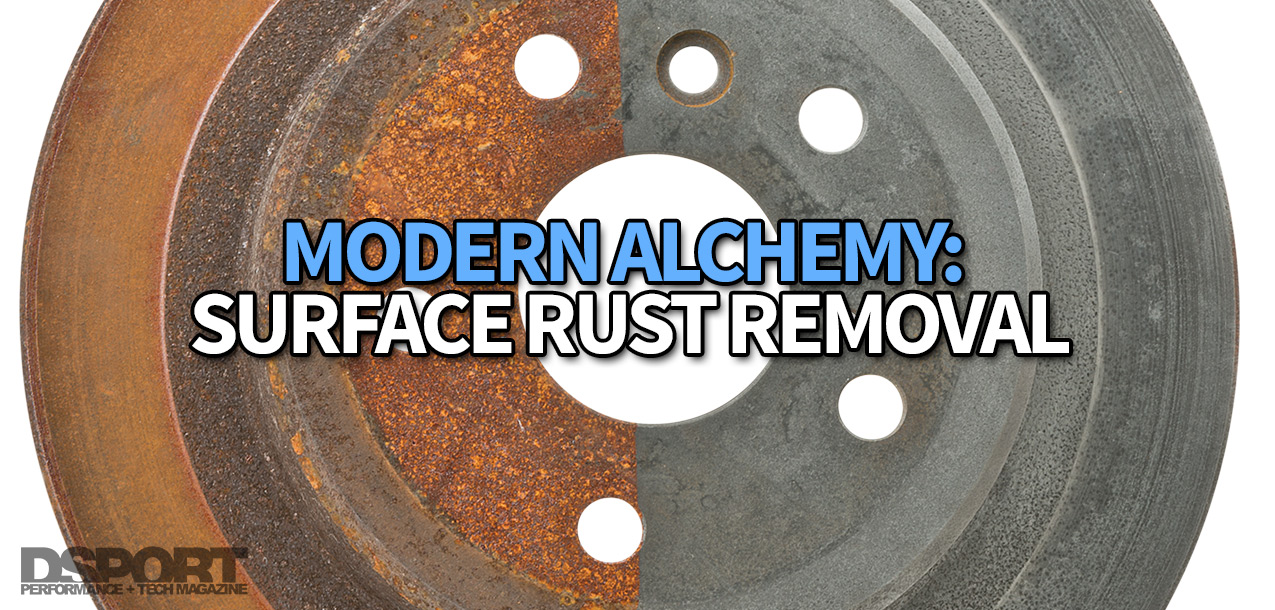

Getting rid of rust used to involve aggressive chemical soaks (or application) that would not only require close monitoring, but also specialized environmental controls and specific handling procedures. Scientific advances in the last decade have produced solutions for chemically removing rust without affecting the undamaged base material. In addition, these products are non-toxic, non-flammable, non-caustic and biodegradable. Geared for both the average consumer and the professional, these solutions provide an effective means of rust removal.

In this section, we tested Eastwood’s Rust Dissolver and Rust Dissolver Gel, along with Evapo-Rust® rust remover. These non-toxic solutions employ specialized chemical compositions that focus on iron oxide while leaving most other materials unaffected. While taking different approaches to rust removal, these products offered surprisingly similar results.

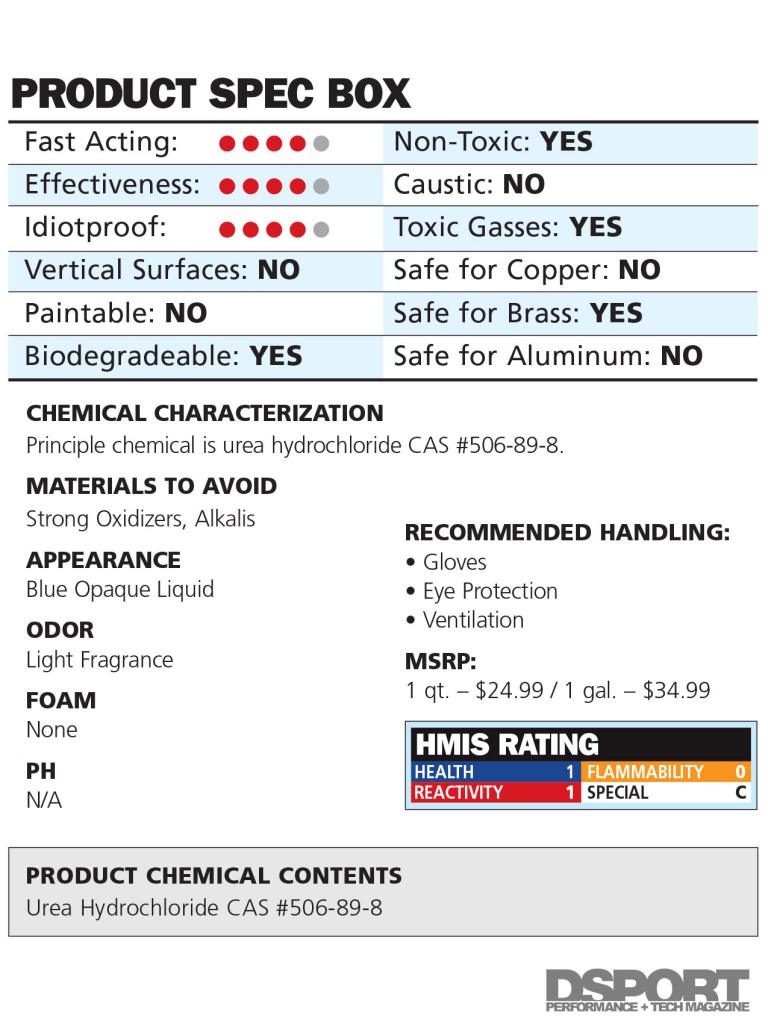

Eastwood Rust Dissolver

Dip and Dissolve Rust

The Eastwood Rust Dissolver liquid submersion formula is based on urea hydrochloride CAS #506-89-8. This water-soluble chemical attacked the surface rust within the first 15 minutes, but required more time to penetrate the deeper-rooted oxidation. At 45 minutes, the pitting was all that remained, while at two hours the pitting had almost completely dissolved. Four hours into the soak, all signs of oxidation had disappeared. This solution releases thermal carbon dioxide and carbon monoxide, so proper ventilation when using this product is essential. Although the Rust Dissolver worked at a slightly slower pace compared to acids, it proved very effective and was much safer to use. Once the Rust Dissolver had been rinsed from the sample, it left the steel in a raw and unprotected state. At this point, it is ready to be etched and painted, powder coated or chromed. A light coating of Rust Dissolver serves as short term protection from flash oxidation. Although it’s stated to be harmless to a number of materials, we found that exposure to raw aluminum caused etching and after an hour, caused significant deterioration.

The Eastwood Rust Dissolver liquid submersion formula is based on urea hydrochloride CAS #506-89-8. This water-soluble chemical attacked the surface rust within the first 15 minutes, but required more time to penetrate the deeper-rooted oxidation. At 45 minutes, the pitting was all that remained, while at two hours the pitting had almost completely dissolved. Four hours into the soak, all signs of oxidation had disappeared. This solution releases thermal carbon dioxide and carbon monoxide, so proper ventilation when using this product is essential. Although the Rust Dissolver worked at a slightly slower pace compared to acids, it proved very effective and was much safer to use. Once the Rust Dissolver had been rinsed from the sample, it left the steel in a raw and unprotected state. At this point, it is ready to be etched and painted, powder coated or chromed. A light coating of Rust Dissolver serves as short term protection from flash oxidation. Although it’s stated to be harmless to a number of materials, we found that exposure to raw aluminum caused etching and after an hour, caused significant deterioration.

Rust Dissolver effectively removed rust within four hours but once rinsed from the sample, did not prevent oxidation from reoccurring.

Rust Dissolver effectively removed rust within four hours but once rinsed from the sample, did not prevent oxidation from reoccurring.

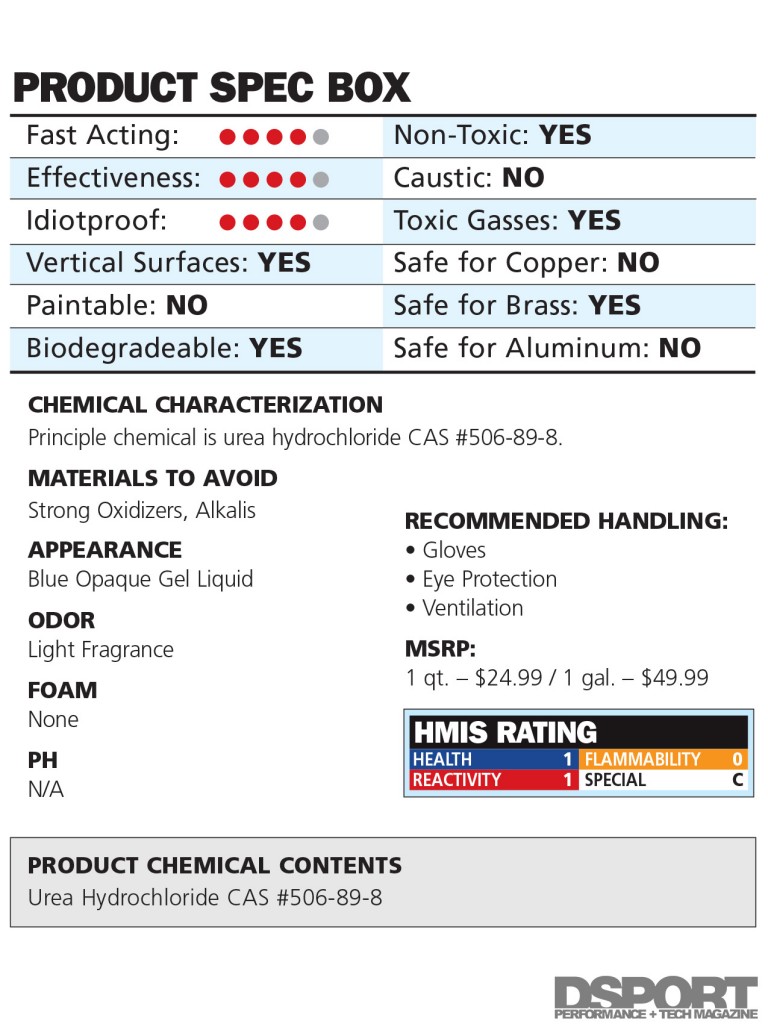

Eastwood Rust Dissolver Gel

Remove Rust At Any Angle

The Eastwood Rust Dissolver gel, like its liquid submersion sibling, is also based on urea hydrochloride CAS #506-89-8. Applied by brush, the gel functions in a similar fashion to the liquid, but can be used on vertical surfaces such as body panels and cage tubing. The gel was applied to the tubing only once for the evaluation and was positioned upright for the entire duration of the test. Light surface rust was eliminated almost immediately, while deeper pockets of rust required two hours to be dissolved. In some cases, additional applications of gel may be required. For extremely rusty parts, Eastwood recommends prepping the surface with a wire brush to dislodge loose oxidation prior to application of the gel. Be sure to apply the gel in a well-ventilated area as the reaction releases carbon dioxide and carbon monoxide. Although the Rust Dissolver Gel is said to be safe for a variety material surfaces, be sure to avoid long-term exposure or contact with aluminum. Our aluminum test sample suffered etching and degradation after one hour of exposure.

The Eastwood Rust Dissolver gel, like its liquid submersion sibling, is also based on urea hydrochloride CAS #506-89-8. Applied by brush, the gel functions in a similar fashion to the liquid, but can be used on vertical surfaces such as body panels and cage tubing. The gel was applied to the tubing only once for the evaluation and was positioned upright for the entire duration of the test. Light surface rust was eliminated almost immediately, while deeper pockets of rust required two hours to be dissolved. In some cases, additional applications of gel may be required. For extremely rusty parts, Eastwood recommends prepping the surface with a wire brush to dislodge loose oxidation prior to application of the gel. Be sure to apply the gel in a well-ventilated area as the reaction releases carbon dioxide and carbon monoxide. Although the Rust Dissolver Gel is said to be safe for a variety material surfaces, be sure to avoid long-term exposure or contact with aluminum. Our aluminum test sample suffered etching and degradation after one hour of exposure.

Rust Dissolver Gel worked at a similar pace to its liquid sibling, but can be applied to vertical surfaces too.

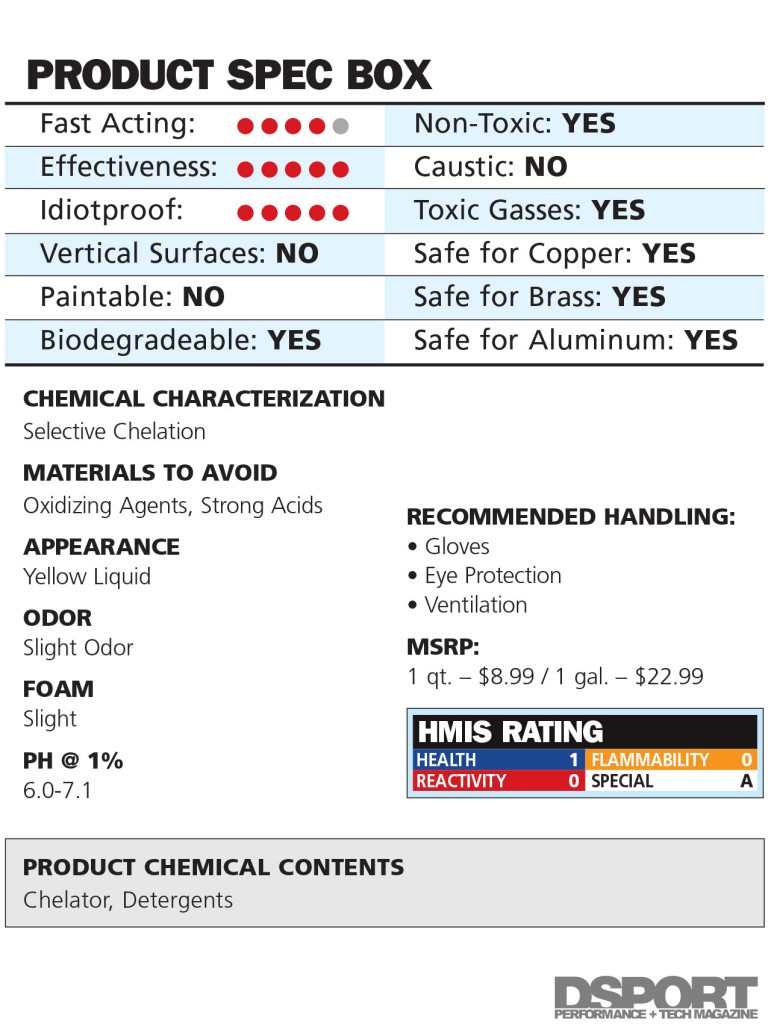

Evapo-Rust® Super Safe Rust Remover

Safe, Easy and Effective

Evapo-Rust® Super Safe Rust Remover takes a different approach to attacking rust. Using a process called “selective chelation,” Evapo-Rust’s chemical makeup contains large synthetic molecules that bond specifically to the iron oxide and then hold them in solution. Evapo-Rust recommends soaking intervals ranging from one to twelve hours, with extremely rusted parts requiring an overnight soak. Light surface rust had been removed within the first fifteen minutes, while practically no oxidation could be seen after one hour. Extended soaking up to four additional hours proved superfluous, showing no further improvement to the surface finish. The solution can be reused until the solution turns black or stops effectively removing rust. In most cases, it can be disposed of down the drain. Evapo-Rust claims to be safe for practically everything, including metals, rubber, plastics, PVC, Viton and most paints. We observed that the solution didn’t have any effect on the aluminum, copper, or brass pieces tested for a duration of one hour. This consumer-friendly chemical seems to deliver on its company’s promises.

Evapo-Rust® Super Safe Rust Remover takes a different approach to attacking rust. Using a process called “selective chelation,” Evapo-Rust’s chemical makeup contains large synthetic molecules that bond specifically to the iron oxide and then hold them in solution. Evapo-Rust recommends soaking intervals ranging from one to twelve hours, with extremely rusted parts requiring an overnight soak. Light surface rust had been removed within the first fifteen minutes, while practically no oxidation could be seen after one hour. Extended soaking up to four additional hours proved superfluous, showing no further improvement to the surface finish. The solution can be reused until the solution turns black or stops effectively removing rust. In most cases, it can be disposed of down the drain. Evapo-Rust claims to be safe for practically everything, including metals, rubber, plastics, PVC, Viton and most paints. We observed that the solution didn’t have any effect on the aluminum, copper, or brass pieces tested for a duration of one hour. This consumer-friendly chemical seems to deliver on its company’s promises.

Evapo-Rust removed rust fairly quickly and when applied after treatment, defends against flash rusting for two weeks.

Evapo-Rust removed rust fairly quickly and when applied after treatment, defends against flash rusting for two weeks.

Page 3: Corrosives For Cleaning