EVIL85

While E85 offers great performance potential at a low price, there are evils associated with this fuel that must be recognized to safely exploit its benefits. The drawbacks of E85 are all results of the fuel’s reduced energy density, its varying quality, its higher flash point, its hydroscopic nature and its limited history of use in the United States.

While E85 offers great performance potential at a low price, there are evils associated with this fuel that must be recognized to safely exploit its benefits. The drawbacks of E85 are all results of the fuel’s reduced energy density, its varying quality, its higher flash point, its hydroscopic nature and its limited history of use in the United States.

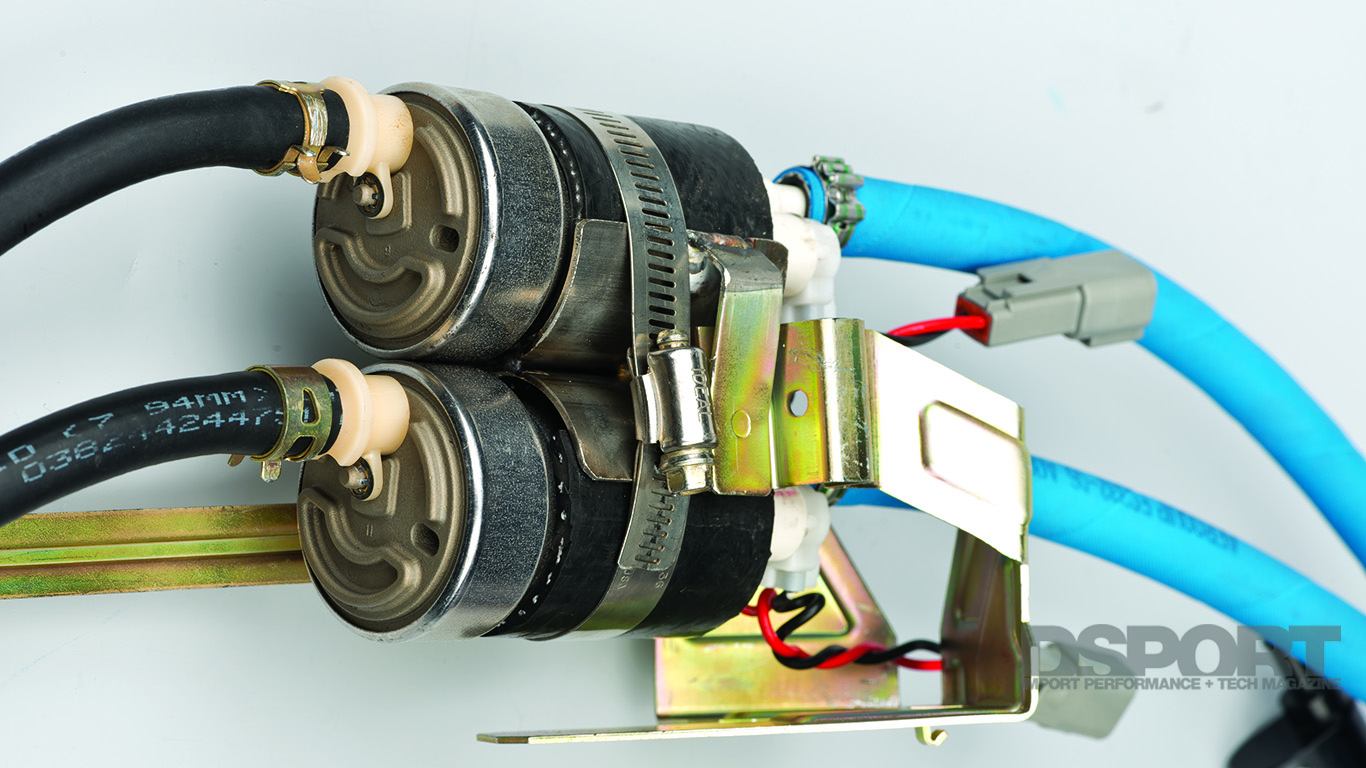

The reduced energy density of E85 reduces vehicle range while increasing fuel supply demands. So how is range affected? Well, not as bad as you may think. Since pump gas is no longer 100-percent gasoline (it’s actually a blend of 10-percent ethanol with 90-percent gasoline, a.k.a. E10), it has an energy density of about 110,000 BTU per gallon of fuel. E85 has an energy density close to 82,000 BTU per gallon. This means that E85 has roughly 75-percent of the energy of E10. As a result, a vehicle’s range is reduced by 25- percent. If you only get 200 miles on a tankful of pump gas in your EVO XIII, you’ll only get 150 miles with E85 in the tank. As for increased fuel supply demands, E85 will require the fuel system to supply 35- percent more fuel for a given horsepower level. That means the pump(s), lines, regulator, injectors and return must all support 35- percent more volume at the same pressure as before.

[pullquote]E85 DISPENSED AT THE PUMP MAY SPEC OUT TO E85 ON ONE FILL-UP AND E65 ON ANOTHER[/pullquote]E85’s varying quality (in terms of the actual percentage of ethanol content) can wreak havoc on E85 users that do not have an engine management system that is flex-fuel compatible. In these cases, the E85 dispensed at the pump may spec out to E85 on one fill-up and E65 on another fill-up (a common problem in areas with cold winters. In cases where a car is finely tuned to extract maximum performance from a true E85 blend, it may experience engine-damaging detonation when run on ethanol blends with a lower percentage of ethanol content (when the ECU is not able to adapt for the change in ethanol percentage).

One reason that E85 varies in its actual percentage of ethanol content is because some regions change to a winter blend that may be E70 or E65. The winter blend is used because the flash point (temperature at which liquid E85 begins to transition to a vapor or gaseous state) is about 55 degrees Fahrenheit. When the outside temperature falls below this, starting a vehicle on E85 becomes an extreme challenge. Blends with less ethanol, like E65 or E70, have lower flash points. Lower flash points allow better ignitability in low temperatures.

The final two evils of E85 are centered on its hydroscopic nature and its limited history of use. Due to its hydroscopic nature, E85 attracts moisture from the air. The end result is a buildup of water in the fuel system. This water can cause damage to injectors, pumps, lines and regulators, if not properly addressed. When storing E85, it’s important to avoid metal containers as the water can oxidize the interior and introduce rust into the fuel. As for keeping the fuel system in order, avoiding long storage period with E85 in the fuel tank is rule number one. From there, running pump gasoline (E10) every third or fourth tankful (on flex fuel equipped setups) should eliminate nearly all of the potential problems from E85’s hydroscopic nature. Pump gas’ higher gasoline content provides for improved lubrication of all moving parts within the fuel system, as well as superior upper cylinder lubrication of the engine itself.

[pullquote]AVOIDING LONG STORAGE PERIODS WITH E85 IN THE FUEL TANK IS RULE NUMBER ONE[/pullquote]Of course, not everything is known about all of the potential pitfalls associated with long-term usage of E85. Component compatibility and longevity with E85 use is still up in the air. While some components and materials may show no ill effects with E85 usage at room temperature, elevated temperatures with E85 may show problems on these same components and materials. In one case, this was evident on certain polymer fuel lines used in the engine compartment that were close to heat sources.