When Magnus Ohlaker (head machinist and engine assembler at Club DSPORT’s Engine Development Facility) was asked “what is your favorite aftermarket engine?”, we never expected Magnus to say the Subaru EJ257. Later, we learned it was because Magnus had assembled over 400 of these engines while working at Cosworth Engineering. […]

Read More

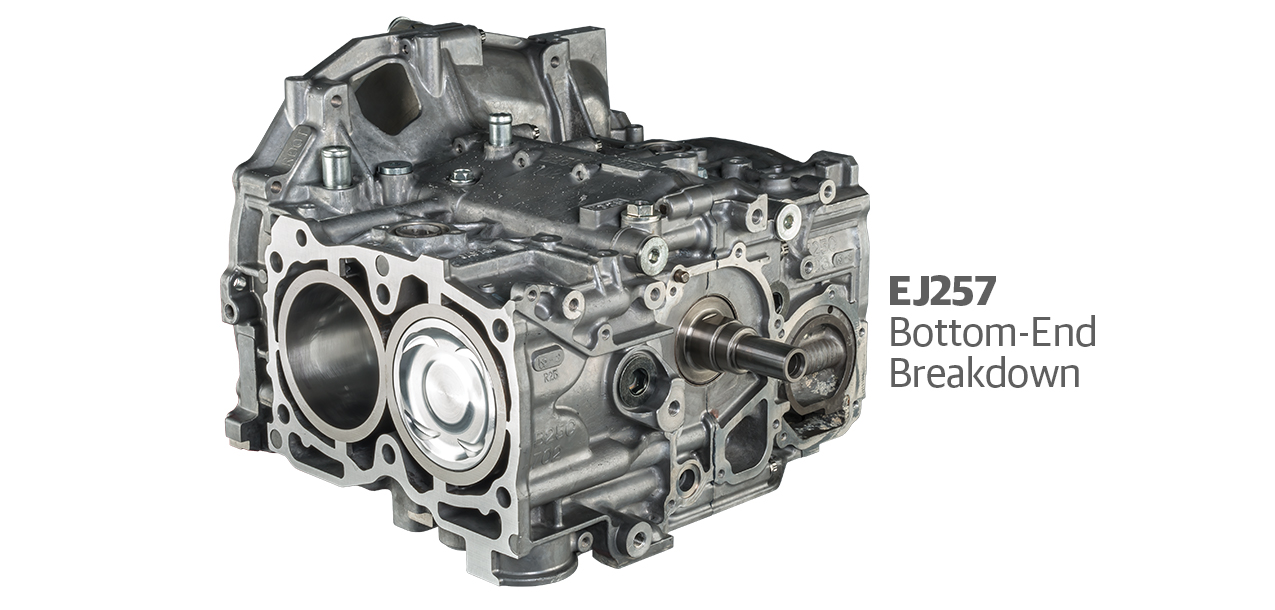

Engine Tech 201: Bottom End | Pistons, Rods, Cranks, Bearings and Sleeves

It’s been said that “You have to start from the bottom, if you want to get to the top.” The same can be said about building a top-performing engine. One needs to start building up the bottom end if they wish to realize top-level performance. Whereas turbochargers, superchargers, camshafts and […]

Read More

Quick Tech: Using Dry Ice When Inserting Cylinder Sleeves

Over in our machine shop, we show you the benefit of using the dry ice to fit in your cylinder sleeves more easily. • Insert cylinder sleeves into cooler of dry ice and heat engine block to 250 ºF . • Remove engine block after 30 minutes of heating. • […]

Read More

L.A Sleeve Releases Big Bore Sleeve Kit For The EJ25

PUNCH OUT THE BOXER AS THE SAYING GOES, THERE IS NO REPLACEMENT FOR DISPLACEMENT AND L.A. Sleeve has made it easier for Subaru owners to up the displacement of their EJ25 engines with its Big Bore Sleeve Kit. L.A. Sleeve’s kit is made from proprietary Moly2000 centrifugally spun cast ductile […]

Read More