Prepping For Launch

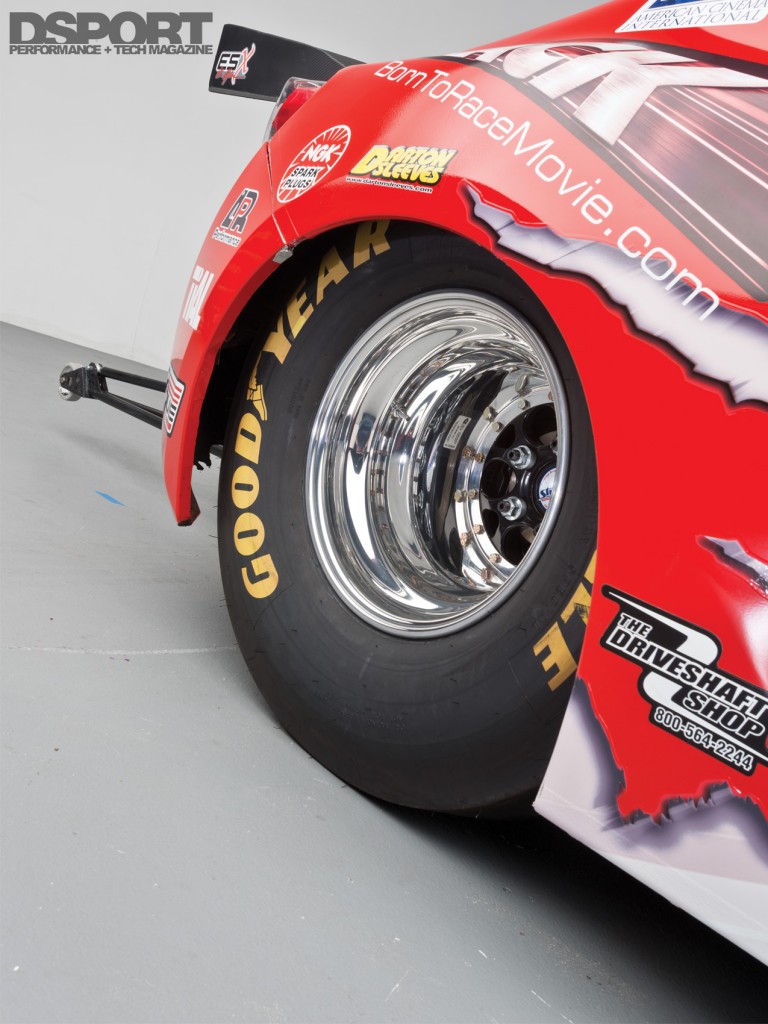

While Easy Street worked on setting up the engine bay, Overkill Fabrication set up the BRZ chassis for 7-second passes. First reduced to a bare shell, the BRZ chassis was then back halved before receiving an SFI 25.1 compliant cage. The factory rear suspension got scrapped in favor of a trailing arm suspension with a custom 9.5-inch solid axle rear-end. This conversion would be essential for putting down the power by way of massive 15×15-inch Weld drag wheels mounted with massive 33×17 Goodyear drag slicks, a task the stock Y38 differential and stock suspension would never be able to reliably accomplish. Carbon-fiber panels replaced the back seats, shielding the driver from track debris kicked up by the slicks.

100-percent CH4O

Afshar chose methanol as his racing fuel for a number of reasons, a key one being its chemical intercooling capacity. Afshar said, “We decided to run pure methanol as it not only cools the compressed aircharge but it also cools the cylinders, which enabled us to eliminate the weight and complexity of a complete cooling system and radiator.” Methanol has less energy capacity than gasolines, thus a greater volume must be delivered in order to produce optimum power. A positive byproduct of having to run larger volumes is that it helps to absorb heat and chemically intercools the cylinders. But keep in mind, methanol is very corrosive, so it is not ideal for streetcar engines and fuel systems.

Power Transfer

[pullquote]THIS TRANSMISSION OFFERED GREATER CONSISTENCY AND POWER CAPACITY, WHICH AFSHAR DEMANDED OF THE BUILD[/pullquote] Once the engines returned to the shop, Easy Street Motorsports began fitting the drivetrain. With a Pro Torque 6000 torque converter mated to the crankshaft, a Coan Racing custom 3-speed TH400 transmission transfers the power to the solid axle rear end by way of a carbon-fiber propeller shaft from The Driveshaft Shop. This transmission offered greater consistency and power capacity, which Afshar demanded of the build. A Precision Performance Products shifter delivers driver input to the slick shifting automatic box.

T-Minus Testing And Counting

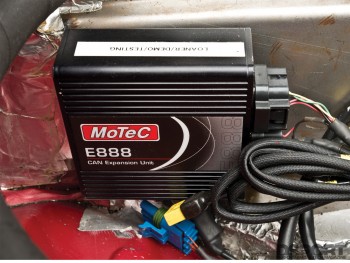

With the finishing touches applied to the BRZ, it was finally ready for final tuning and testing. On an engine dyno, the Ron Hendrix and Tony Rigoli engines performed comparably, each putting down 1,600 horsepower and 1,350 lb-ft torque to the crankshaft. Once installed in the ZC6 chassis, a complete MoTeC electronics suite manages and monitors all aspects of vehicle operation. As MoTeC’s James Nero refines the maps at the track, Afshar looks confidently toward the record. He commented, “We’ve barely finished the carl in just a three-month window. The car has received an incredible response and has made appearances on several television programs including the Jeff Probst Show and charity functions too. So far, we’ve only taken the car out a couple of times. But the testing has been promising, as we’ve already surpassed the standing 60-ft and 330-ft records. We plan to make a full pass soon and hopefully set the record too.” With experience and knowledge combined with the right support and alignment of the stars, Afshar’s aspirations to shoot for the moon could soon become a reality.

With the finishing touches applied to the BRZ, it was finally ready for final tuning and testing. On an engine dyno, the Ron Hendrix and Tony Rigoli engines performed comparably, each putting down 1,600 horsepower and 1,350 lb-ft torque to the crankshaft. Once installed in the ZC6 chassis, a complete MoTeC electronics suite manages and monitors all aspects of vehicle operation. As MoTeC’s James Nero refines the maps at the track, Afshar looks confidently toward the record. He commented, “We’ve barely finished the carl in just a three-month window. The car has received an incredible response and has made appearances on several television programs including the Jeff Probst Show and charity functions too. So far, we’ve only taken the car out a couple of times. But the testing has been promising, as we’ve already surpassed the standing 60-ft and 330-ft records. We plan to make a full pass soon and hopefully set the record too.” With experience and knowledge combined with the right support and alignment of the stars, Afshar’s aspirations to shoot for the moon could soon become a reality.