Dry Carbon-fiber…. In house!

Carbon-fiber parts are lighter and stronger than their fiberglass counterparts… when they are constructed properly. Wet carbon-fiber parts are subjected to the same process as fiberglass. Thus, a major pitfall is that air bubbles can get trapped in the weave and between layers, forming weak points in a part. Dry carbon fiber is impregnated with resin, so the chance of bubbles forming is eliminated. In addition, dry carbon fiber is vacuum bagged and cured in an autoclave to ensure uniform heating of the resin and formation of the part. This process allows the manufacturer to produce a stronger product that weighs less.

A Better Way To Fly

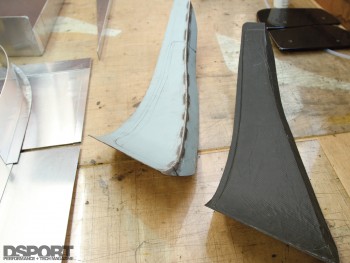

Once back at Revolution’s shop in Saitama, Aoki began mocking up the pieces he wanted to make out of dry carbon-fiber. Revolution has an autoclave in house, enabling Aoki to make his own dry carbon-fiber pieces. At the front, ports in the bumper force-feed air through carbon-fiber ducts around the inner tire well and out through the wide- fender vents. He also fashioned a set of twin canards for additional downforce. At the rear, the diffuser also benefitted from additional canards and air channels, while the rear wing layout was improved. Revisions were made to the rear suspension geometry to further improve handling.

Managing Airflow

*Numbers (#) reflect pictures above from left to right, top to bottom

At the rear of the chassis a custom dry carbon-fiber wing- stay (1) unites to the rear section of the RE Amemiya GT300 shell while symmetrical lattice bracing (2) reinforces the back-halved chassis. Effectively managing airflow is key to generating downforce so under chassis ducting (3) helps channel air toward the rear diffusers (4) for greater adhesion and handling. Ducting in the front bumper (5) along with dual canards (6) help manage air into the chassis and around the front suspension (7) while the large vented fenders (8 and 9) efficiently help evacuate high pressure air to increase downforce.

Cross Ported?!

For a rotary engine, porting the rotor housing is like installing larger camshafts on a piston engine. The most common rotary ports are the street port, bridge port and the peripheral port. Aoki-san elected to use a combination of two ports referred to as a “cross port”. This is a combination of a peripheral port and a street port. He claims that by employing both porting methods, the transient response of the engine is improved and more power is produced under the curve.

Race For The Record

At the 2010 Rev Speed Tsukuba Super Battle, the Hankook-Revolution TA-2 was prepared to break records. With endurance driver Yasushi Kikuchi behind the wheel, the TA-2 broke the RWD class record with a scorching best lap time of 0’53”673. This lap time was a mere 0’00”084 from matching the HKS CT230R overall record. What’s particularly noteworthy is the fact that no power enhancements were made. Instead, refining aerodynamics and suspension resulted in a more than two-second improvement. When asked about the outcome, Aoki comments, “We’ve still got more time to extract from the TA- 2. We’re making a few more changes before the 2011 World Time Attack Challenge in Australia. We’re aiming for bragging rights to be called the ‘Worlds Fastest Tuning Car.’ Then we’re going to aim for the HKS record at Tsukuba in December.” With the right combination of parts, tuning and determination, you can expect this FD to start a tuning revolution in 2011.