The Power

The Power

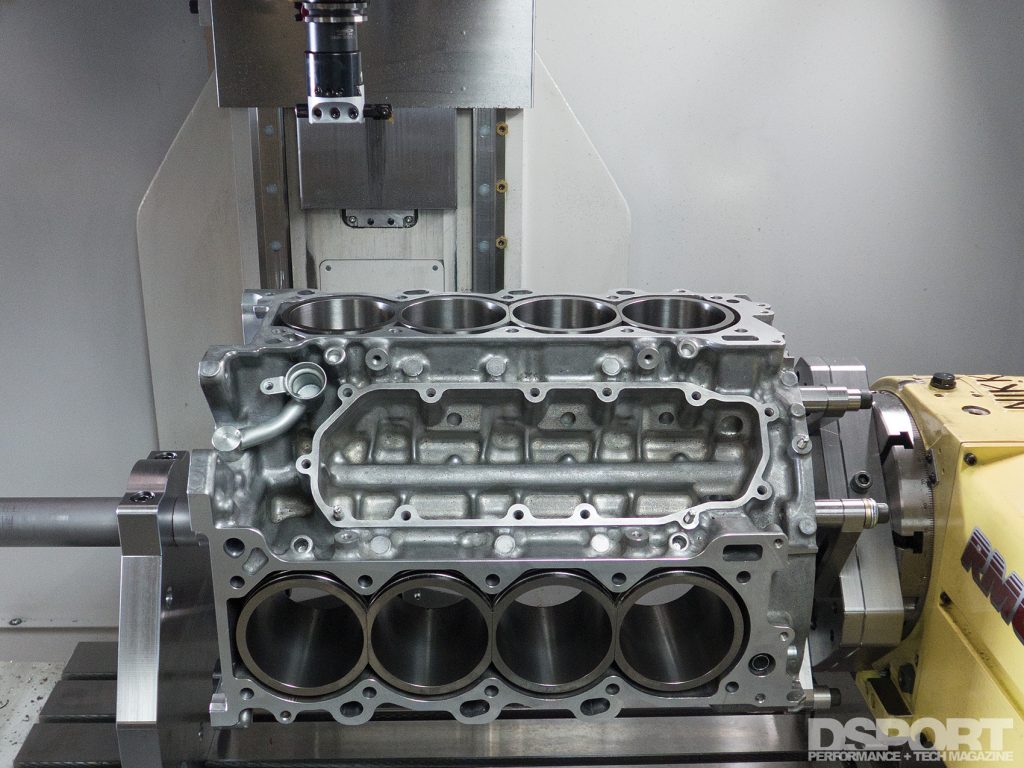

The Toyota 2UR-GSE was a completely new engine to everyone at DSPORT. We knew that we needed to make it more powerful, but we needed to first get familiar with it. After teardown and analysis was complete, we learned a great deal about this engine. For starters, we like it. We like it a lot! The block itself is designed to be incredibly strong. No less than 6 bolts secure each of the main caps on the engine. Main webs are extremely strong too. The cylinder bore spacing was 105.5mm, which provided for potential. The more we looked at the block, the more we kept thinking about building 1,500 and 2,000 horsepower variants. When we focused back at the task at hand, we found a forged crankshaft, well-designed cylinder heads, high-lift camshafts and titanium valves. Of course, we also found two things that we didn’t like. The OEM connecting rods didn’t appear to be engineered to handle much more additional power and the factory exhaust manifolds looked to have “fit” much higher on the design list than function. It’s our guess that 20-30 horsepower would be available with a set of better designed headers. Unfortunately, we don’t know if it would be possible to make a better set that would fit in the chassis too. Also, the factory camshafts featured some rather complex manufacturing that would require some serious time and money to develop upgraded replacements.

So how would we be able to generate more power? We decided to keep it simple and increase the engine’s displacement. Based on the bore spacing and other critical dimensions within the engine, we decided that an increase in bore size from 94mm to 99.5mm would do the trick. We sent the block to LA Sleeve for further inspection and to allow them to take the measurements needed to produce a set of amphibious sleeves for the 2UR-GSE.

Magnus Ohlaker of Club DSPORT machined the block to accept the new amphibious sleeves. These sleeves locate on a shelf machined into the original cylinders which secure to the block by means of a slight interference fit. The process was captured on video and it’s worth watching. The new sleeves were bored to size before being fitted with custom CP Pistons and Carrillo connecting rods. The CP Pistons were designed to deliver the OE compression ratio while the Carrillo rods were designed to handle over 200 horsepower per cylinder. While it’s definitely overkill for now, the engine is capable of handling 1,600 horsepower or more. The completed assembly also required O-ringing of the cylinders to work with the modified factory head gasket which was never intended to seal a 99.5mm bore. While the original displacement checked in at 4,969.5cc, the new engine’s displacement is 5,568.1cc. This raises output of the engine to 525 horsepower and 440 lb-ft of torque. Since the fuel demands are just 12-percent more than the original, we may be lucky enough to have the factory ECU get the job done without recalibration (something we don’t personally have direct access to doing on this platform). In endurance racing configuration with a race exhaust in place, we see no reason why 600 horsepower couldn’t be approached and possibly exceeded.

The Next Chapter

The 2015 SEMA show marked our first SEMA car build with an OEM. Our Ford Fiesta ST garnered awards and respect from many. For SEMA 2016, we had the opportunity to handle the engine development for one of the most photographed and talked about cars at the show. While we haven’t been told about the final plans for this LC560 concept, we hope to be a part of many more Lexus performance builds. Since this car has 2,000 horsepower looks, we think it only makes sense to build a 2,000 horsepower engine to do it justice. However far fetched, it’s on our Christmas list.

THE PRESS RELEASE

A racing-inspired version of the Lexus LC 500, created by Gordon Ting/Beyond Marketing, debuted today at the 2016 SEMA Show. The world’s first customized LC 500 features aerodynamic body work, upgraded suspension, brakes, wheels, tires, and new interior executed by Evasive Motorsports and an engine build imagined by Hard Media, Inc. and DSPORT Magazine, turning the Lexus 5.0-L V8 engine, which is also shared with RC F and GS F, into a 5.6-L with 525 horsepower.

One of the major challenges presented by this first modified Lexus LC coupe was that the project started with an early developmental prototype a full year before the vehicle hit the market with zero accessory and aftermarket support. Using a very early vehicle, Gordon Ting/Beyond Marketing were able to work with their partners to help drive development of the first body kit, performance suspension and brake kits for this new model which could be on the market in spring of 2017 when the LC goes on sale.

“The LC 500 looks beautiful and has a fantastic foundation of performance and driving characteristics,” said Gordon Ting, Beyond Marketing. “I wanted to use that groundwork to develop a high-performance, aggressive-looking LC 500 that is tough yet luxurious, and has serious chops thanks to the custom engine.”

The body of the LC 500 was prepped by Signature Autobody for the Avery Dennison Gloss Yellow wrap. Aerodynamic upgrades include an Artisan Spirit Custom Lexus LC Kit, featuring custom fender flares, a front diffuser, side skirts, a rear diffuser and rear wing. KW Suspension featuring a Hydraulic Lift System with a height adjustable spring kit rounds out the performance enhancements. The four corners of the vehicle feature 22” HRE P101 wheels in satin charcoal with Pirelli P Zero Nero Tires, and are accented by Brembo brakes with a custom caliper color. Carbon fiber Sparco race seats accompany the Evasive Motorsports GT3 spec race interior and safety cage.

In the LC 500, the Lexus 5.0-L naturally aspirated V8 engine offers 471 horsepower and 398 lb-ft of torque. For the modified LC 500, Club DSPORT increased the displacement to 5.6-L, and increased the cylinder bore to 99.5mm (as compared to 94mm) for 525 horsepower. Custom Moly-2000 Amphibian Sleeves from LA Sleeve were used to increase the bore size while custom CP Pistons and Carrillo connecting rods were engineered to perform up to 9,000 RPM. The design, machining and assembly of the engine was done in-house at Club DSPORT’s engine development facility. The work was performed by Magnus Ohlaker, who has 20 years of experience building championship winning F1 and IndyCar engines. While not exploited at this juncture, the power handling capabilities of the 2UR-GSE engine have been more than doubled.