You’ve probably been told or heard from someone that “an internal combustion automotive engine is just a sophisticated air pump.” Here’s the truth. What you have been told isn’t entirely accurate. First, a pump is a device used to move fluids and it operates at relatively low pressures. Air is not a fluid, but instead a gaseous mixture. Second, the primary purpose of an internal combustion engine is not to pump fluids or compress air. The engine’s purpose is to perform energy conversions to produce horsepower. Internal combustion engines turn the chemical energy in the fuel into thermal-pressure energy in the cylinder through combustion. Finally, the engine converts this pressure energy into mechanical energy at the flywheel. Of course, even the worst analogies have some sort of basis in truth. So what’s the real relationship between internal combustion engines and air? It’s really simple. Internal combustion engines need the oxygen in air to be able to combust the fuel. When a higher mass of air can be ingested by the engine, more fuel can be added and combusted. The result of burning more fuel is a production of more thermal energy; which in turn means more power (as long as exhaust restrictions don’t prevent us from getting the combustion products out of the engine).

Text & Photos by Michael Ferrara

Commentary by Allan Lockheed

Volumetric Efficiency

Even if you don’t know too much about engines, you probably know your engine’s displacement. Displacement is “how big your engine is” in the redneck vernacular. For example, you might have a 1.8-liter, 2.0-liter or 3.0-liter. This number represents the entire volume of all of the cylinders in the engine.

Volumetric efficiency, or VE for short, is an important term to understand. VE represents the ratio of the volume of air actually ingested into the engine compared to its displacement. Displacement does not include the clearance and combustion chamber volume. If an engine is 2.0-liters in displacement and at a certain engine speed (RPM) it’s able to take in 80 percent of 2.0-liters (1.6-liters of air), then the volumetric efficiency of this engine at that rpm is 80 percent. The volumetric efficiency of an engine varies with engine speed. The volumetric efficiency of an engine will increase with engine rpm from idle until the engine reaches peak torque. At peak torque, volumetric efficiency will be at its peak value. When engine speed is increased past the peak torque rpm, then the volumetric efficiency will decrease until redline.

Volumetric efficiency, or VE for short, is an important term to understand. VE represents the ratio of the volume of air actually ingested into the engine compared to its displacement. Displacement does not include the clearance and combustion chamber volume. If an engine is 2.0-liters in displacement and at a certain engine speed (RPM) it’s able to take in 80 percent of 2.0-liters (1.6-liters of air), then the volumetric efficiency of this engine at that rpm is 80 percent. The volumetric efficiency of an engine varies with engine speed. The volumetric efficiency of an engine will increase with engine rpm from idle until the engine reaches peak torque. At peak torque, volumetric efficiency will be at its peak value. When engine speed is increased past the peak torque rpm, then the volumetric efficiency will decrease until redline.

Improving Volumetric Efficiency (VE)

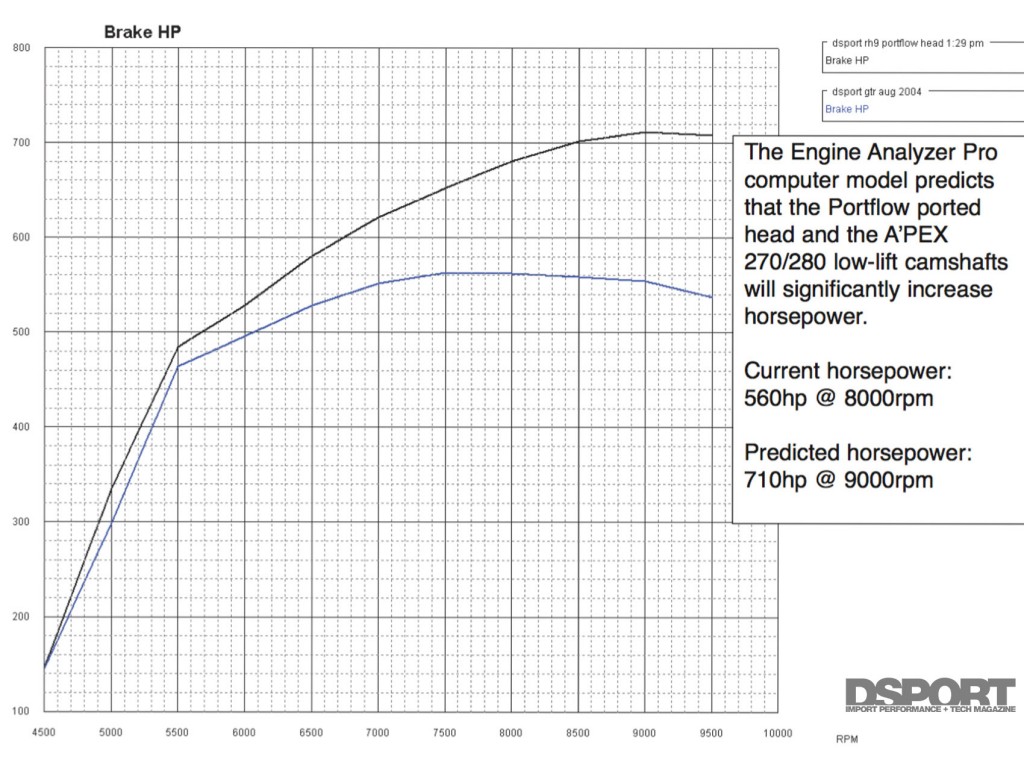

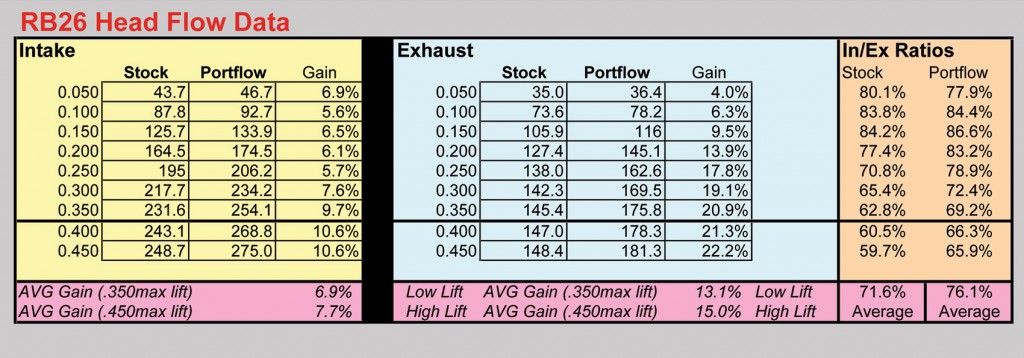

When you can increase the volumetric efficiency of an engine, you can increase the amount of air that gets into the engine. When the proper amount of additional fuel is added, additional horsepower is the result. So how do you improve the volumetric efficiency of an engine? The simple ways to improve volumetric efficiency involve eliminating the restrictive components in the path of air flow into the engine and exhaust out of the engine. A low-restriction, air-filter allows more air to get into the cylinder during the intake stroke of the engine. On the exhaust side, a better-flowing exhaust system can provide that all of the exhaust gas exits the cylinder on the exhaust stroke. As a result, a higher volume from fresh air is available on the next intake stroke. In general, these basic improvements will provide additional power and volumetric efficiency at nearly all engine speeds, from idle to redline. Basic cylinder head porting, as explained in part one (May 2004 issue), can also provide improved volumetric efficiencies at all engine speeds. However, more aggressive cylinder head porting may provide additional volumetric efficiencies at higher rpm while trading off some lower rpm performance.

When you can increase the volumetric efficiency of an engine, you can increase the amount of air that gets into the engine. When the proper amount of additional fuel is added, additional horsepower is the result. So how do you improve the volumetric efficiency of an engine? The simple ways to improve volumetric efficiency involve eliminating the restrictive components in the path of air flow into the engine and exhaust out of the engine. A low-restriction, air-filter allows more air to get into the cylinder during the intake stroke of the engine. On the exhaust side, a better-flowing exhaust system can provide that all of the exhaust gas exits the cylinder on the exhaust stroke. As a result, a higher volume from fresh air is available on the next intake stroke. In general, these basic improvements will provide additional power and volumetric efficiency at nearly all engine speeds, from idle to redline. Basic cylinder head porting, as explained in part one (May 2004 issue), can also provide improved volumetric efficiencies at all engine speeds. However, more aggressive cylinder head porting may provide additional volumetric efficiencies at higher rpm while trading off some lower rpm performance.

Camshafts: VE Controllers

Camshafts orchestrate the valve opening and closing events in relation to crankshaft and piston position in the cylinder of your engine. As a result, camshafts are the most influential engine component with respect to volumetric efficiency. While camshafts are a subject in themselves, it’s only important to understand the following for our discussion. All other factors being equal, higher lift camshafts will improve the volumetric efficiency of the engine at all engine speeds (this assumes that the head flows additional air when the valve is opened higher). Longer duration camshafts will tend to improve volumetric efficiencies at higher engine speeds while sacrificing volumetric efficiencies at lower engine speeds. As a result, longer duration camshafts will tend to move the peak torque to a high engine speed (rpm). Intake centerline, exhaust centerline, lobe center and overlap are also influential performance parameters. For example, the right amount of overlap occurring at the right crankshaft position can result in removal of all of the combustion gases while the clearance volume of the engine is filled with fresh fuel and air. This can result in a VE bonus of five to 10 percent. However, we will not cover these in this installment. Instead, we will limit our scope on camshafts to lift and duration only.