Ignition

Six coils individually fired (as opposed to wasted-spark) are about as good as an OEM ignition gets. While awesome in its capabilities as a factory ignition, these sophisticated DIS systems are generally very costly to modify. We have had great experience with CD ignition systems from the likes of MSD, Crane and Accel. MSD and Crane also offer a number of multi- channel systems specifically for DIS-type ignitions. However, the Nissan RB26 ignition system requires six independent ignition drivers, as opposed to the three required on a six-cylinder wasted-spark DIS system. This means you need to buy two six-cylinder DIS boxes. Considering that we didn’t want to spend a weekend wiring up an ignition and we couldn’t find enough free space under the hood, we decided to take a different approach.

Six coils individually fired (as opposed to wasted-spark) are about as good as an OEM ignition gets. While awesome in its capabilities as a factory ignition, these sophisticated DIS systems are generally very costly to modify. We have had great experience with CD ignition systems from the likes of MSD, Crane and Accel. MSD and Crane also offer a number of multi- channel systems specifically for DIS-type ignitions. However, the Nissan RB26 ignition system requires six independent ignition drivers, as opposed to the three required on a six-cylinder wasted-spark DIS system. This means you need to buy two six-cylinder DIS boxes. Considering that we didn’t want to spend a weekend wiring up an ignition and we couldn’t find enough free space under the hood, we decided to take a different approach.

Our answer would be the B&M New Volt power unit. The B&M New Volt power unit steps up the voltage going to the ignition coils. Best of all, the unit doesn’t care if it feeds a single coil or multiple coils. In our case, we measured 13.0 volts going to our ignition coils (with the engine running) before the installation of the B&M New Volt power unit. After the simple three-wire installation of the unit, we measured 21 volts at the coil. This 60- percent increase in voltage translates into an identical 60-percent increase in ignition power.

Fuel

We performed the calculations and knew that we needed to have fuel injectors that would be able to flow enough for up to 950 horsepower. We had already had Venom build us a set of 950cc injectors that would get us close, but 1000cc  injectors would be the exact match. We gave a call to Blitz and had them deliver a set of six 1000cc injectors that would fit the original fuel rail without modification. Only the Nissan injector clips had to be changed to work with the Blitz injectors. With the Blitz injectors installed, we now needed to concentrate on getting enough fuel to the injectors.

We performed the calculations and knew that we needed to have fuel injectors that would be able to flow enough for up to 950 horsepower. We had already had Venom build us a set of 950cc injectors that would get us close, but 1000cc  injectors would be the exact match. We gave a call to Blitz and had them deliver a set of six 1000cc injectors that would fit the original fuel rail without modification. Only the Nissan injector clips had to be changed to work with the Blitz injectors. With the Blitz injectors installed, we now needed to concentrate on getting enough fuel to the injectors.

Our current, fuel supply system consists of an A’pex Integration N1 in-tank pump and factory fuel lines. This is an adequate fuel system up to about 650 horsepower at the flywheel (roughly 550 horsepower at the wheels).

On the dyno, we quickly learned that the horsepower limits of the N1 pump were for real. Once we reached 600 horsepower at the wheels, we couldn’t get the air/fuel ratio any richer than 12-to-1. At 655 horsepower at the wheels (roughly 770 horsepower at the flywheel), the air/fuel ratio could not get richer than 12.6-to-1. The injectors could be completely opened, but only so much fuel could get into the engine. Our current fuel supply system is maxed out.

The time has come to design a fuel supply system capable of providing enough fuel for 900 to 1000 horsepower at the flywheel. We gave a call to Bob Milar at Weldon. Bob has designed fuel systems on many of the quickest and fastest cars running in the IDRC Auto Trader Magazines Championship Drag Racing Series. What we learned from Bob will probably fill a complete article on fuel delivery systems in the future. However, we were intrigued by some of Bob’s insights and would like to share some now.

The time has come to design a fuel supply system capable of providing enough fuel for 900 to 1000 horsepower at the flywheel. We gave a call to Bob Milar at Weldon. Bob has designed fuel systems on many of the quickest and fastest cars running in the IDRC Auto Trader Magazines Championship Drag Racing Series. What we learned from Bob will probably fill a complete article on fuel delivery systems in the future. However, we were intrigued by some of Bob’s insights and would like to share some now.

We asked Bob for his thoughts on adding a second N1 pump and he responded, “what does one and one equal?” We responded, “Two.” He said, “In fuel delivery systems, one plus one equals 1.65 at most. If the system is designed incorrectly, one plus one could just equal one.” Obviously he had our attention. We cranked out the math with Bob and came up with two viable options. For option one, we could add a second N1 pump plumbed correctly. Our other option would be to install a single Weldon pump with the capacity to meet the fuel demands. No matter which solution, Bob likes to point out that, “a new fuel pump is less expensive than an engine rebuild after you melt a piston.” We couldn’t agree more, especially since we’ve been having all this fun on stock pistons.

–

Next Issue

We promise to get the smaller turbine housings on the vehicle and get our DRAG Sport GT-R back to the drag strip. With the power on tap for the 10s, we’ll definitely be addressing all of the NHRA safety requirements. This means a cage, 5-point harnesses, scattershield and SFI balancer.

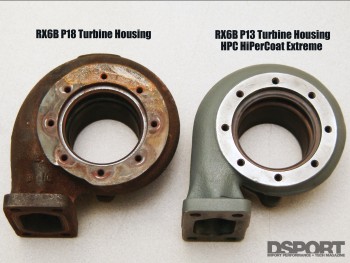

| IHI RX6B Turbine Housings | ||

|---|---|---|

| P13 | A/R 0.51 | 28.1% Smaller, Next Issue |

| P16 | A/R 0.63 | 11.3% Smaller |

| P18 | A/R 0.71 | Current |

| P20 | A/R 0.79 | 11.3% Larger |