The Ideal Cam

So how do you get the perfect cam? A cam that has tremendous low-end torque, a 10,000 rpm redline, an idle like mom’s car and a broad powerband from idle to redline doesn’t really exist. In many ways, cams can be compared to turbochargers in the way that each part may significantly influence the character of the engine. Just like there isn’t a turbo that will provide instant response and 1,000 horsepower on your four-cylinder, there isn’t a camshaft that will maximize power at every engine speed. Fortunately, choosing the right aftermarket performance camshaft for your particular combination will deliver big rewards. Increased power, increased torque, increased rpm potential and a broader powerband are just a few of the benefits that could result from choosing the right cam. While a quality set of cams requires a decent investment, there is a good chance that aftermarket cams may be the best performance investment that you make.

Lift, Lobes and Symmetry

Lift, Lobes and Symmetry

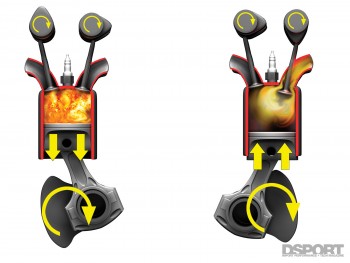

For every action, there is always a reaction. From a performance standpoint, the faster a valve opens and reaches full-lift, the better. Why? Horsepower is directly related to how much air and fuel can be stuffed into the cylinder. Air and fuel can’t get into the cylinder unless the valves are open. Camshafts that quickly open the valves are said to have an aggressive lobe profile. Unfortunately, the laws of physics govern the maximum amount of possible valve acceleration, also known as “aggressiveness.” If the camshaft profile tries to accelerate the valve too fast, excessive wear or valvetrain problems can occur. When returning a valve to its seat, a camshaft once again cannot do this too fast or the valve slams into the valve seat (sometimes valves even bounce off the seat). Most modern cam designs optimize valve acceleration rates by designing camshafts with asymmetric lobes. This style of lobe lifts the valve quicker than it lowers the valve. Quite simply, asymmetric lobe designs can be utilized to maximize the performance available while increasing the durability of the valvetrain.

Types of Engines

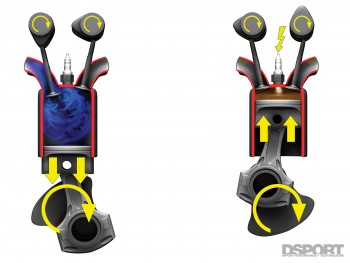

[pullquote]THE OHC DESIGN IS SUPERIOR TO THE OHV IN THREE WAYS[/pullquote]There are two basic styles of piston engines in production today: the overhead-valve engine (OHV) and the overhead-cam engine (OHC). Overheadvalve engines rely on valve lifters, pushrods, rocker arms and a camshaft that rests in the engine’s cylinder block. Examples of OHV engines include most of the domestic V8 and V6 engines manufactured over the last 50 years. The OHC design is superior to the OHV in three ways. First, the OHC design eliminates the pushrods and, in some cases, the rocker arms (which are called cam followers on OHC engines). With less moving parts, reliability increases. Second, the absence of pushrods allows the use of more aggressive camshaft profiles which improve the engine’s volumetric efficiency. When pushrods are present in a valvetrain system, the added mass will induce valve float at an early rpm if too aggressive a profile is used. Third, the OHC design lends itself well to three-, four- or five-valves-per-cylinder designs. Four-valves-per-cylinder heads have allowed today’s smaller displacement engines incredible specific outputs.

Knowing the Specs

Since camshafts influence when an engine starts making power, when it stops producing power, maximum power output, fuel economy, idle quality, and engine efficiency, it is important to understand camshaft specifications. With this basic understanding, you will be better able to select the camshaft that will keep you ahead of the competition.

Lift and Duration

On many applications, a single camshaft controls the opening and closing events of all the valves in an engine, while other applications may implement as many as four camshafts to control the valve events. Regardless of the number of cams, the rules that apply for single-camshaft engines also apply to those with multiple camshafts.

The most well-known camshaft specifications are lift and duration. Most manufacturers give specifications for lift at the valve, instead of at the camshaft. On some applications that don’t use a rocker assembly, these two lifts may be the same. If you need to convert from lift at the camshaft lobe to lift at the valve, use the following equation:

Valve Lift = Lobe Lift x Cam Follower Ratio

Peak Valve Lift

Peak valve lift is nothing more than a measurement of the maximum distance the valve is opened. Assuming all other specifications remain the same, choosing a camshaft with more lift will increase the flow of air and fuel into an engine and the flow of exhaust out of an engine. As a result, more power can be made. In many cases, camshafts that have increased lifts over stock specifications and near stock duration will offer increased performance without making measurable sacrifices in “driveability.” Everything has a limit, and cylinder heads will generally reach a point where airflow no longer increases with an increase in valve lift. Before you order that mega-lift cam, please consider the following: When valve lift is dramatically increased, the possibility of valve-to-piston contact, coil bind at the valve spring and valvetrain interference is also increased. To avoid bent valves, broken retainers and thin wallets, always use the necessary complementary valvetrain components and check valve-topiston clearance when recommended by the camshaft manufacturer.

Duration

Duration is the measurement of how long a valve remains open. Along with how high a valve is opened, how long it stays open also influences the performance of an engine. If you are trying to fill a glass of water at the sink, how much you open the faucet, as well as how long you have that valve open, will determine how much water fills the glass. The faucet and glass analogy simply demonstrates the measurement of duration. The duration specification of a camshaft is measured in crankshaft degrees. Contrary to what might be expected, there are actually 720-degrees of crankshaft rotation in a single four-stroke cycle of your engine.

[pullquote]THERE ARE ACTUALLY 720-DEGREES OF CRANKSHAFT ROTATION IN A SINGLE FOUR-STROKE CYCLE OF YOUR ENGINE[/pullquote]However, the problem with camshaft duration figures is that different manufacturers measure this duration at different valve lifts. Brand A manufacturer might measure duration from the time the valve is lifted 0.015 inches off its seat until it returns to that same position, while Brand B manufacturer might not start measuring until the valve is 0.050 inches off the seat. The result is that if both companies measure the same camshaft, Brand A might measure 306 degrees of duration (measuring at a minimum lift of 0.015 inches), while Brand B would measure 256 degrees of duration (measuring at 0.050 inches). In essence, the results are two completely different measurements for the same camshaft. Luckily, most camshaft manufacturers now provide duration figures at either a minimum lift of 1mm (Japan’s industry standard of measure) or a minimum lift of 0.050 inches (the traditional U.S. hot rod standard). When duration comparisons between two camshafts are being made, only compare the figures if the measurements have been taken at the same minimum lift.

Duration and Power

In most cases, more lift translates into more power and torque across the powerband. In general, increased duration will shift the torque and horsepower peak to a higher rpm, and if all the other specifications are the same, increasing duration will yield more top-end and mid-range power, while sacrificing low-end torque. Shifting the powerband to higher rpms along with the use of a longer duration camshaft and the appropriate valvetrain components, will raise an engine’s redline. One rule of thumb is that for every 10 degrees of increase in duration (measured at 1mm or 0.050 inches) will shift the torque peak and redline up by 500 rpm.