By varying the size of each of the pistons in the caliper, the pad wear can be equalized to minimize pad taper.

Overall Brake Leverage

Brake pedal feel (soft or firm) and brake pedal travel are functions of both the brake pedal mechanical ratio and the hydraulic ratio between the area of the brake master cylinder and the total piston area of the front or rear brake calipers. Here is how it all works. Let’s say we have an R33 GT-R V-spec. Since it is a factory power-assisted brake vehicle, it’s likely that the pedal ratio is between 3.5:1 and 4.5:1. For the purpose of this example, we will make the assumption that it is 4.0:1 assumption (you can get the actual ratio by measuring the OEM pedal assembly). The master cylinder on this vehicle is 27mm (1-1/16”). Taking the diameter of the bore, we can calculate the piston area of the master cylinder to be 0.887 square inches. By doing the math to calculate the total piston area of all eight pistons on the front brake system (2×4-pot calipers), we end up with a total piston area of 8.22 square inches for the front Brembo Calipers (38mmx4, 44mmx4). If we divide the caliper piston area by the master cylinder area, we end up with a hydraulic ratio of 9.27:1. Multiplying the two ratios together, we end up with a 37.1:1 overall brake leverage ratio. By itself, this number represents a low travel, high effort pedal. Fortunately, this ratio is OK when power assist is available. When a power brake assist is not being used, a more typical overall brake leverage ratio might be between 50:1 and 70:1. If you have ever lost the vacuum going to your power brake booster on your R33 GT-R, you can see how hard the pedal needs to be pushed in order to stop the vehicle.

Racing brake fluids are available from a number of manufacturers. Many brake companies recommend DOT 3 and DOT 4 based racing fluids with high boiling points for track use. Be sure to flush your fluid every year to maintain the highest boil protection possible.

Brake Fluid

High performance brake fluid has performance advantages over the factory fill fluids. Since a hydraulic system depends on fluid remaining a fluid to operate properly, a high-performance brake fluid’s ability to resist boiling is critical. Once a brake fluid boils, brake performance suffers dramatically. Since the boiling point of brake fluids is highly influenced by the moisture content, you should flush out your brake fluid every season for maximum performance.

Brake Lines (Hard and Flexible)

The brake lines carry the pressure created in the brake master cylinder to the calipers. Hard lines don’t change much even under high pressure but the factory rubber flexible brake lines will tend to expand under high line pressures. This equates to a bit of a sponge feel in the pedal. Upgrading the flexible lines to a much less compliant Teflon inner, stainless-steel braided outer brake line reduces this issue dramatically.

Brake Bias Control

In speaking about brake system bias, it’s important to understand that the ratio of master cylinder to caliper area as well as the rotor diameter will all influence the brake bias in terms of brake torque applied to the front and rear wheels. The ABS system often has a control strategy employed to regulate the pressures to each caliper to avoid a lockup. On manual brake systems, a brake-bias control valve allows the driver to dial in the amount of brake bias desired.

Brake Calipers

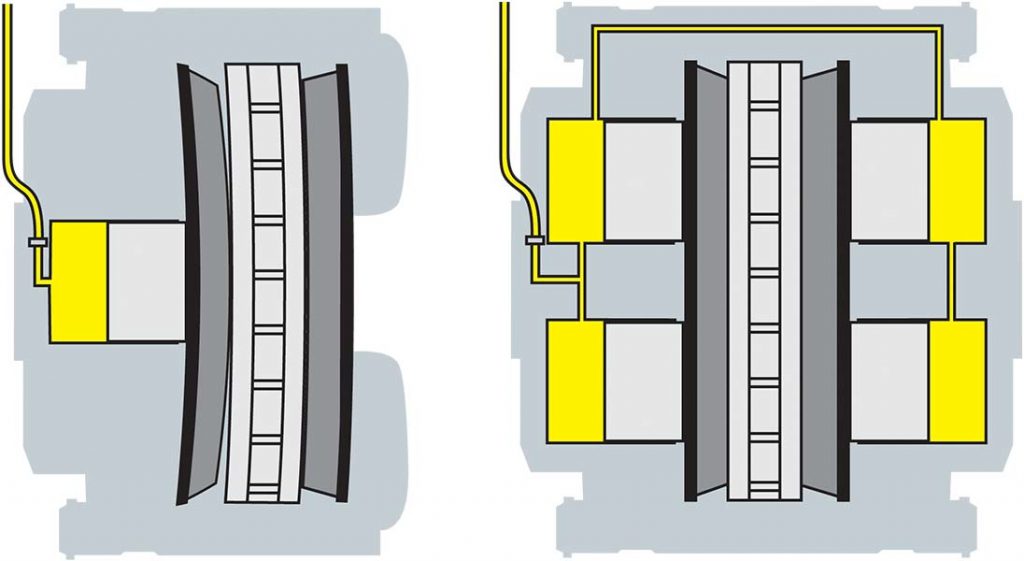

While the first spoken aspect of a brake caliper is often the number of pistons, the number of pistons doesn’t have as big of an impact on performance as many think. By increasing the number of pistons and by using different sized pistons, the goal is to be able to use a larger pad and to still maintain even wear on the pad. More pistons does not mean that a caliper will deliver more brake torque than another caliper. Instead, it’s the total piston area of a caliper that dictates how much brake torque will increase or decrease with a caliper change. In the case of our R33 GT-R, moving from the original Brembo V-spec 4-piston calipers (2x38mm, 2x44mm) to an EVO 8/9 Brembo caliper (2x40mm, 2x46mm) increases the piston area and therefore the brake torque delivered for a given line pressure. The total piston area of the original caliper was 4.11 square inches. The total piston area of the EVO 8/9 caliper was 4.52 square inches. This represents a 10-percent increase in piston area and a resulting 10-percent increase in front brake torque with this upgrade. There is also a resulting increase in brake torque by using a larger diameter rotor. The total increase in brake torque at the front of the vehicle must be offset by a like increase in brake torque at the rear of the vehicle in order for brake bias to remain the same. We will cover the math on this next month.

On the left is a single-piston sliding caliper. On the right is a 4-piston caliper. When the effective caliper piston area is the same, both calipers will produce the same brake torque for a given pressure. However, a 4-piston caliper should deliver more even pad wear.

When selecting an upgraded caliper, the change in total piston area is the primary concern. However, there are also many other important considerations. These include dust boots, piston material and caliper rigidity. Some calipers may not use a dust boot at all as they are intended for limited miles of track use. These may not be the best solution for a street car that sees 25,000 miles of driving per year. Most calipers use pistons made of aluminum or steel. In some cases, titanium pistons are used. Titanium pistons are typically only on the ultra-high-end caliper offerings but they have the advantage of being a better insulator between the brake fluid and the high pad temperatures (titanium is a very good insulator). Caliper rigidity is also a factor in brake performance. Calipers that are more rigid do everything better but come at a substantially higher cost.

Brake Pad Shims

Most OEM pads come with steel shims that go to the back of the pads to help reduce brake noise. For some popular applications, you may be able to find these shims produced in titanium for under $100 per pair of calipers. By replacing the steel shim with a titanium shim, the conductive heat transfer to the caliper’s pistons is dramatically reduced. This in turn can help keep the brake fluid below the boiling point.

Brake Pads

The brake pads and rotors do all of the dirty work in the brake system. Brake pads are made from a variety of materials that are both metallic and non-metallic in nature. The friction material and the corresponding coefficient of friction it produces will directly influence brake torque output. The coefficient of friction is also temperature dependent. This means that the material may get grabbier at elevated temps or it may hit a temp where it starts to get more slippery due to breakdown. Selecting the optimal brake pad material is dependent on so many factors including some you many not even realize. For example, tire selection can influence pad selection. If you are running the vehicle on slicks at the track, the amount of brake torque and temperature will be higher than what can be seen on a street tire. Hence, a pad capable of operating at higher temps may be required. Many teams prefer to run the same brake pad compound at the front and rear of the vehicle. This will mean that the pad compound doesn’t upset the brake bias (assuming the front and rear brakes run at the same temperature). When a bias adjustment is needed its achieved by changing the pressure sent to the rear brakes. There are some that think it is OK to run a different compound pad between the front and rear to influence a brake bias. If you are going to try such a combination be sure to evaluate its effectiveness. As with anything that affects brake bias, it may create more issues than it solves.

Brake Rotors

With the exception of CCM and carbon, nearly all rotors are made from cast-iron. As with any family of material, there are poor and exceptional grades of cast-iron. Lower-priced rotors will typically use lower quality materials. When replacing rotors, be sure to select quality rotors that are either OEM or a premium aftermarket offering. Of all of the components in the brake system, the rotors are one of the only component that affects both the thermal capacity of the system and the brake torque output of the system. The thermal capacity and thermal capabilities of the brake system are often directly related to the mass and design of the brake rotor. The larger the diameter and thickness of the rotor, the higher its heat capacity. When a brake rotor is designed with thermal management in mind, it will be vented with cooling channels designed to accelerate the transfer of heat from the rotor to the surrounding air. The amount of heat capacity needed is proportional to the amount of energy that will need to be dissipated. Both vehicle weight and the frequency and magnitude of the braking required will influence the amount of thermal capacity needed. When more thermal capacity is needed and a larger diameter brake rotor is part of the solution, the increased diameter of the rotor adds a second potential benefit. Increasing the diameter of the rotor increase the brake torque for a give line pressure. In the case of the R33 GT-R, going from a 300mm to 350mm rear rotor increases the brake torque by about 21 percent.

With the exception of CCM and carbon, nearly all rotors are made from cast-iron. As with any family of material, there are poor and exceptional grades of cast-iron. Lower-priced rotors will typically use lower quality materials. When replacing rotors, be sure to select quality rotors that are either OEM or a premium aftermarket offering. Of all of the components in the brake system, the rotors are one of the only component that affects both the thermal capacity of the system and the brake torque output of the system. The thermal capacity and thermal capabilities of the brake system are often directly related to the mass and design of the brake rotor. The larger the diameter and thickness of the rotor, the higher its heat capacity. When a brake rotor is designed with thermal management in mind, it will be vented with cooling channels designed to accelerate the transfer of heat from the rotor to the surrounding air. The amount of heat capacity needed is proportional to the amount of energy that will need to be dissipated. Both vehicle weight and the frequency and magnitude of the braking required will influence the amount of thermal capacity needed. When more thermal capacity is needed and a larger diameter brake rotor is part of the solution, the increased diameter of the rotor adds a second potential benefit. Increasing the diameter of the rotor increase the brake torque for a give line pressure. In the case of the R33 GT-R, going from a 300mm to 350mm rear rotor increases the brake torque by about 21 percent.

Cross-drilling of rotors was a popular practice but many don’t understand the reasoning. Cross-drilling allowed the gasses and brake pad particles to have a place to go. It was not for the purpose of improving the cooling of the rotor. Unfortunately, there is a drawback to this process. The drilled holes reduce the thermal capacity and they can accelerate the formation of cracks in the rotor. Today, slotted rotors are the preferred way of allowing the outgassing of the pad. This process does not reduce the thermal capacity of the rotor or increase the likelihood of crack development.

Large cast-iron rotors can be heavy. Most of the larger diameter brake rotors will be a two-piece design with an aluminum center hat for weight savings. When cost is not an issue, CCM (Carbon-Ceramic Matrix) brake rotors are sometimes employed. These brake rotors are used on a number of supercars. These offer a major weight savings advantage over cast-iron rotors. In the case of our R35 GT-R, we saved nearly 10 pounds per corner switching over from a 2-piece cast-iron rotor to a CCM rotor from Stillen/AP Racing. As this is both sprung and rotational weight, there are numerous advantages to taking weight from this portion of the vehicle.

Improving the cooling to the brake system is one of the least expensive ways to improve braking performance. This cooling allows a smaller mass rotor to perform like a larger mass rotor without cooling.

Improving the cooling to the brake system is one of the least expensive ways to improve braking performance. This cooling allows a smaller mass rotor to perform like a larger mass rotor without cooling.

Brake Cooling Ducts

Perhaps the simplest way to improve the thermal capacity of a brake system is by improving the flow of cool air to the rotors for cooling. This is one area where there is no tradeoff. The more heat that can be carried away by passive or active brake cooling, the better.

ABS System

The Anti-Lock Braking system (ABS) is also the automatic biasing system of a brake system. When a lockup of a wheel is sensed, it has the ability to reduce the line pressure seen by the caliper at the offending wheel. Unfortunately, the ABS system cannot correct for a bias imbalance that an improperly-engineered brake system will deliver. Here is one way to look at it. On a well-designed factory brake system, the chances of any of the four wheels being the first to lose traction should be equal. The is the result of a proper brake bias front to rear on the vehicle. Now, let’s say that you install a big brake kit on the front of your vehicle that increases the front brake torque 40 percent (20-percent from the rotor increase and 20-percent due to a caliper piston area increase). Now the front brakes are going to be the first to lose traction on hard braking while the rear brakes aren’t even close to delivering the brake torque needed to cause a rear tire to lose traction.

Taking a Brake

Pedal assembly, booster, master cylinder, lines, bias valve, calipers, rotors and pads. A list of components that require proper selection to deliver superior braking performance. From part one, you should know how each of the components in the brake system affect performance. For those that love the math, we will show you how to select the right upgrades to maintain the proper brake bias and maximum braking performance.