THE PLAYERS: AEM, ID, WALBRO, XRP

[pullquote]A FLEX-FUEL VEHICLE MUST HAVE AN ENGINE MANAGEMENT SYSTEM AND FUEL SYSTEM OPTIMIZED TO RUN BOTH ON GASOLINE AND ETHANOL[/pullquote]So now you understand the ins and outs of an E85 or flex-fuel conversion. Ideally, street-performance vehicles should be configured for flex-fuel use. This allows all of the benefits of E85 while averting some of the drawbacks. A flex-fuel vehicle must have an engine management system and fuel system optimized to run both on gasoline and ethanol.

AEM Performance Electronics’ newest generation of engine management system, the Infinity EMS, has built-in flex-fuel support. Simply adding a GM flex-fuel sensor (about $450) to the fuel system provides the Infinity EMS with the ethanol content percentage of the fuel being used. With this data, the engine management system simply needs to be tuned in both a pure gasoline and an ethanol-blend (E85 or E98) configuration. Essentially, fuel and ignition maps for both extremes (pure gasoline and the highest percent ethanol-content blend available) are made. The ECU can then use the information from the ethanol-content sensor to blend the tune accordingly.

As previously mentioned, an E85 fuel system must also be capable of supplying 35-percent more fuel than a system set up for gasoline. Previously, we were using RC Engineering 1,600 cc/min injectors. Factoring for 35-percent more fuel, we simply multiple the previous flow rating by 1.35 to get 2,160 cc/min as the desired flow rating. This number was right in line with the Injector Dynamics ID2000 injectors (2,225cc/min rating). Despite the massive flow ratings of these injectors, the saturated coil design allows for incredibly low duty cycles to be run. This allows these big injectors to provide exceptional idle. There is only one Achilles heel with the ID2000s and that is the injectors’ non-compatibility with fuels containing MTBE. The MTBE will damage the ID2000 and reduce their flow rating, so avoid fuels (like Q16) that contain MTBE if using these injectors.

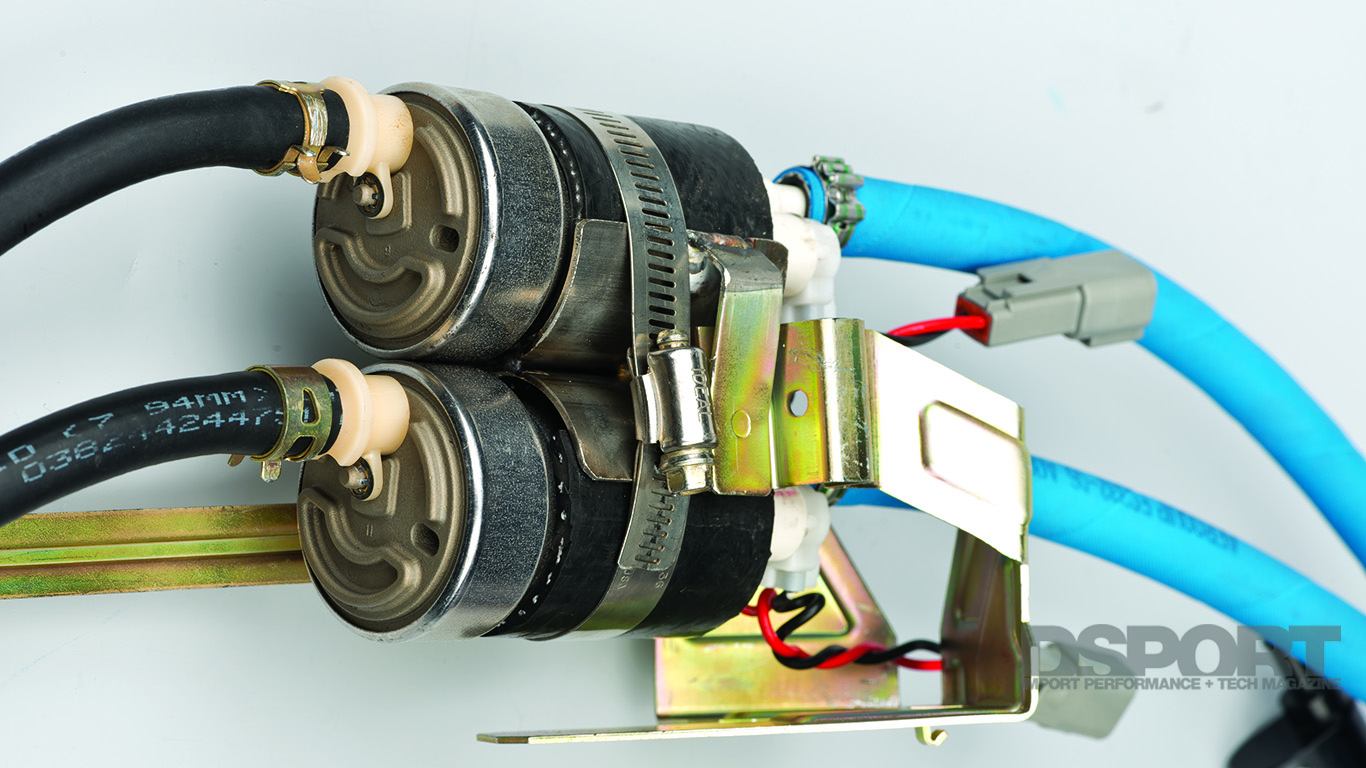

[pullquote]SIMPLY RUNNING BOTH PUMPS AT A 100-PERCENT DUTY CYCLE WILL EXCEED THE LIMITS OF THE REGULATOR[/pullquote]With the injection direction set, we needed to establish that the system was ready to pump it up. Walbro recently released its E85-compatible 400lph pump (p/n F90000267). In our testing, the pumps were able to deliver 250lph of flow at 80psi (the pressure the pump is working at when the boost pressure is at 37psi). Compared to the A’PEXi N1 pumps, the 267s deliver over 45-percent more flow, which is ideal for our conversion. Of course, this much additional flow requires a staged or pulse-width-modulated (PWM) solution to drive the fuel pumps. Simply running both pumps at a 100-percent duty cycle will exceed the limits of the regulator. As a result, the fuel pressure will exceed the desired base level. An overrun of fuel return will heat up the fuel too. We’ll address the solutions to these issues in part two of the E85 files.

Finally, the fittings and lines must also be E85 compatible. We relied upon XRP, a leading producer of performance fittings and plumbing, to ensure that we had the proper performance fittings and fuel hose in the system. According to XRP, anodized aluminum performance fittings will have no issue with E85 assuming that no corners were cut in the anodizing process. As for the hoses, XRP suggests its professional-level HS-79 ultra-lite, flexible smooth-bore PTFE (Teflon) hose assemblies for E85 applications. This is the same hose used by the majority of the Top Fuel and Funny Car teams. The HS-79 features a 4-ply or 5-ply construction (when ordered with the optional CSM fifth layer) which delivers superior flow rates, reduced pressure drop, tight bend radius, universal fluid compatibility and minimized weight. The PTFE inner tube is extremely chemically resistant to any type of fuel. Since it has a smooth-bore construction, it doesn’t have the flow disturbances presented in convoluted hoses. The second, third and fourth plies of the HS-79 hose work together to deliver superior strength and pressure capabilities without impacting flexibility. The silicone outer tube, stainless-steel wire braid reinforcement and aramid (Kevlar) layers use specific fiber and wire angles to maximize strength while maintaining maximum flexibility. The optional fifth layer (CSM) provides added abrasion resistance and an easy-to-clean surface. We employed this hose from the pump hat fittings forward to the fuel rail and back from the regulator to the tank.

Finally, the fittings and lines must also be E85 compatible. We relied upon XRP, a leading producer of performance fittings and plumbing, to ensure that we had the proper performance fittings and fuel hose in the system. According to XRP, anodized aluminum performance fittings will have no issue with E85 assuming that no corners were cut in the anodizing process. As for the hoses, XRP suggests its professional-level HS-79 ultra-lite, flexible smooth-bore PTFE (Teflon) hose assemblies for E85 applications. This is the same hose used by the majority of the Top Fuel and Funny Car teams. The HS-79 features a 4-ply or 5-ply construction (when ordered with the optional CSM fifth layer) which delivers superior flow rates, reduced pressure drop, tight bend radius, universal fluid compatibility and minimized weight. The PTFE inner tube is extremely chemically resistant to any type of fuel. Since it has a smooth-bore construction, it doesn’t have the flow disturbances presented in convoluted hoses. The second, third and fourth plies of the HS-79 hose work together to deliver superior strength and pressure capabilities without impacting flexibility. The silicone outer tube, stainless-steel wire braid reinforcement and aramid (Kevlar) layers use specific fiber and wire angles to maximize strength while maintaining maximum flexibility. The optional fifth layer (CSM) provides added abrasion resistance and an easy-to-clean surface. We employed this hose from the pump hat fittings forward to the fuel rail and back from the regulator to the tank.

In the tank, we used XRP’s push-on hose. This hose was chosen since XRP’s Ensure clamps can secure it to the barbed fittings coming out of the fuel pumps. This hose uses a three-ply construction consisting of a chlorinated polyethylene elastomer (CPE) inner tube, a reinforcing textile braid and a CPE outer construction. Since CPE is more permeable than PTFE, a “gas smell” can occur when this hose is used on a vehicle stored in a trailer or closed garage. While the level of permeation is not dangerous (unless fuel lines are run in the vehicle’s interior), it can be an odor nuisance. Since we are using the CPE-based hose in the tank, the permeation will have no effects. Because the XRP push-on hose has the same outer material as inner material, a visual inspection of the outer hose can be an indicator to the condition of the inner. At the temperatures seen in the fuel tank, we expect to see a long life from this CPE hose. However, we would not recommend this hose for E85 use outside of the tank. For those applications a PTFE inner core hose is a must.