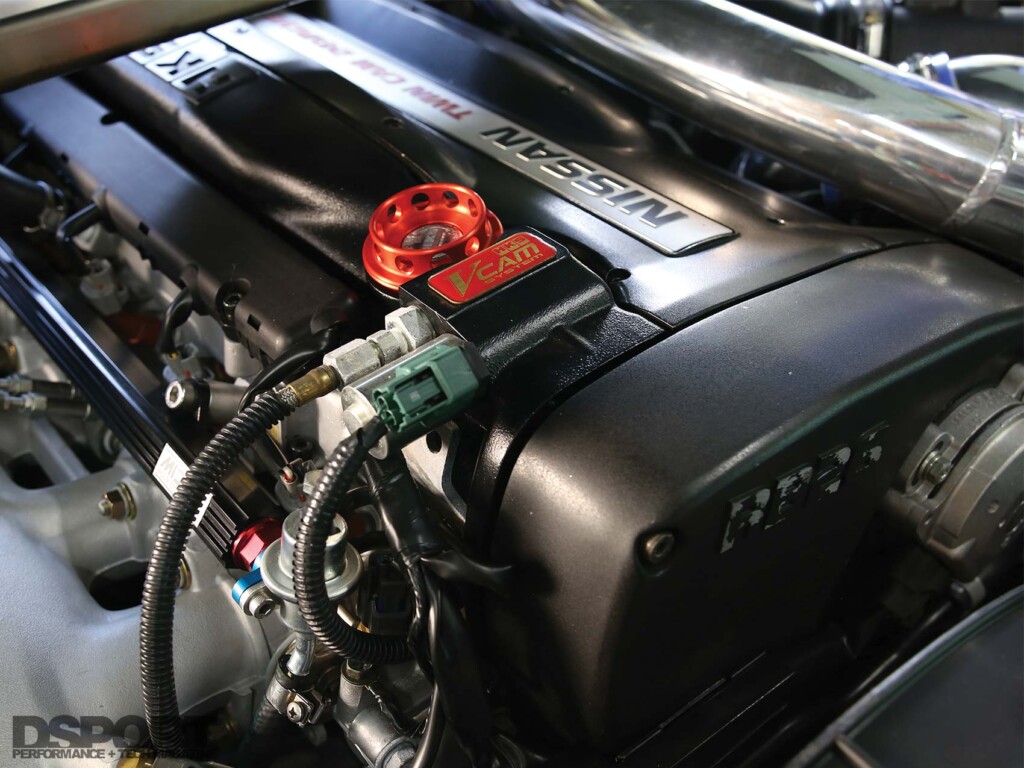

While the recent influx of RB-powered GT-Rs has caused a flood of RB engine builds, DSPORT has been developing the RB26 engine for the past 20 years. While others are relying upon an abundance of misinformation on the internet, we know what works and what doesn’t and we’ve been the first to evaluate many new technologies for the engine platform. Back in 2004 working with Tom Fujita of Port Flow Design, we started testing and development with the RB26 cylinder head. We found that the right porting of the RB26 cylinder head combined with the right camshafts could turn a 505 horsepower engine into a 626 horsepower engine. Later, we experimented with larger valves, different cams and even variable intake cam timing control to understand what the RB26 engine likes and dislikes in terms of cylinder head modifications. Today, Club DSPORT has the knowledge to optimize the cylinder head for anything from a stock rebuild to a race-ready setup capable of supporting over 1,600 horsepower at 11,000RPM.

By Michael Ferrara // Photos by DSPORT Staff and HKS

DSPORT Issue #232

Cam-Head Benefits

Ignorance is bliss and many still don’t understand that boost pressure is a measurement of the pressure of the air not getting through the engine. When we look at two engines of the same displacement where one has a higher volumetric efficiency (VE) than the other engine, the higher VE engine will require less boost pressure to reach a certain power level. Let’s say it took about 21psi of boost pressure to make 500 horsepower on a stock RB26 fitted with upgraded turbos. If we installed a ported cylinder head with upgraded camshafts to increase the VE of the engine, it may only require 14psi of boost pressure to realize 500 horsepower. If the wastegate is manipulated to increase the shaft speeds to move enough air to get the boost back up to 21psi, the engine will now make 625 horsepower. These aren’t theoretical numbers but actual results from our testing. The bottom line is that an improved camshaft and cylinder head combination on the RB26 will allow you to make the same power at a lower boost level or more power at the same boost level. Peak power gains on the order of 20-to-40 percent are achievable. In simple terms, if you make an investment into the right parts and work for the RB26 cylinder heads, you’ll be very happy with the results.

Ignorance is bliss and many still don’t understand that boost pressure is a measurement of the pressure of the air not getting through the engine. When we look at two engines of the same displacement where one has a higher volumetric efficiency (VE) than the other engine, the higher VE engine will require less boost pressure to reach a certain power level. Let’s say it took about 21psi of boost pressure to make 500 horsepower on a stock RB26 fitted with upgraded turbos. If we installed a ported cylinder head with upgraded camshafts to increase the VE of the engine, it may only require 14psi of boost pressure to realize 500 horsepower. If the wastegate is manipulated to increase the shaft speeds to move enough air to get the boost back up to 21psi, the engine will now make 625 horsepower. These aren’t theoretical numbers but actual results from our testing. The bottom line is that an improved camshaft and cylinder head combination on the RB26 will allow you to make the same power at a lower boost level or more power at the same boost level. Peak power gains on the order of 20-to-40 percent are achievable. In simple terms, if you make an investment into the right parts and work for the RB26 cylinder heads, you’ll be very happy with the results.

R32/R33 vs. R34 GT-R

All RB26 intake camshafts are interchangeable across the R32, R33 and R34 engines. The exhaust cams between the R32 and R33 are also interchangeable but the R34 exhaust cam is unique. The difference between the R32/R33 GT-R and R34 GT-R exhaust is simply the drive key for the Cam Angle Sensor (CAS). If you have an R32/R33 and find an R34 set of cams, you will need to use the CAS from the R34 GT-R.

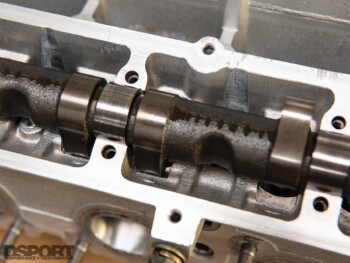

Low-Lift vs. High-Lift

RB26 camshafts can be lumped into low-lift and high-lift categories. Low-lift cams do not require modification of the cylinder head to provide clearance for the cam lobes. Low-lift cams are also usually compatible with the OEM pistons as the amount of lift increase over the OEM camshaft is limited. In many cases, low-lift cams are designed to work with OEM springs (assuming they are still meeting the OEM spec for pressure). Since low lift cams do not significantly increase the valve lift, they don’t make large gains in the engine’s volumetric efficiency. While low-lift cams will generally deliver power gains on the order of 10-to-20 percent, they will definitely not perform as well as high-lift camshafts. However, for an upgrade that can run under $700 for a pair of cams, it still provides good bang for the buck.

RB26 camshafts can be lumped into low-lift and high-lift categories. Low-lift cams do not require modification of the cylinder head to provide clearance for the cam lobes. Low-lift cams are also usually compatible with the OEM pistons as the amount of lift increase over the OEM camshaft is limited. In many cases, low-lift cams are designed to work with OEM springs (assuming they are still meeting the OEM spec for pressure). Since low lift cams do not significantly increase the valve lift, they don’t make large gains in the engine’s volumetric efficiency. While low-lift cams will generally deliver power gains on the order of 10-to-20 percent, they will definitely not perform as well as high-lift camshafts. However, for an upgrade that can run under $700 for a pair of cams, it still provides good bang for the buck.

High-lift camshafts are a requirement for extracting maximum performance from the RB26 engine. The minimum cost of going the high-lift camshaft route is considerably more expensive. While the camshafts are the same price, the high-lift conversion will require a spring upgrade at the very least. When lifts are above a certain spec (usually about 10.5~10.85mm of lift), a spring and retainer upgrade is often required. When the base-circle is reduced, aftermarket +1mm thickness valve lifters (or longer valves) are often needed to offset the reduced base circle. On top of $1,000 in additional parts, additional machine work is needed on the cylinder head to clearance for the high lift camshaft. While this process used to be a nightmare when done by hand, Club DSPORT built a special fixture to do the machining in a 4-axis CNC. The process costs $250, takes about 15 minutes once the head is loaded and delivers beautiful results. On the contrary, the old fashion method of using a grinder would take many hours. This frustrating process often produced some results that looked like a nightmare too. While the high-lift cam route is going to cost about $1,250 more than the low-lift route (or about $2,000 less than running the OEM cams), the rewards of going the high-lift route are immense. For anyone going through the process of building an RB26 engine that will have upgraded pistons (with deeper valve reliefs for higher-lift cams), it would be a serious injustice to not maximize the performance of the engine with a high-lift camshaft upgrade.

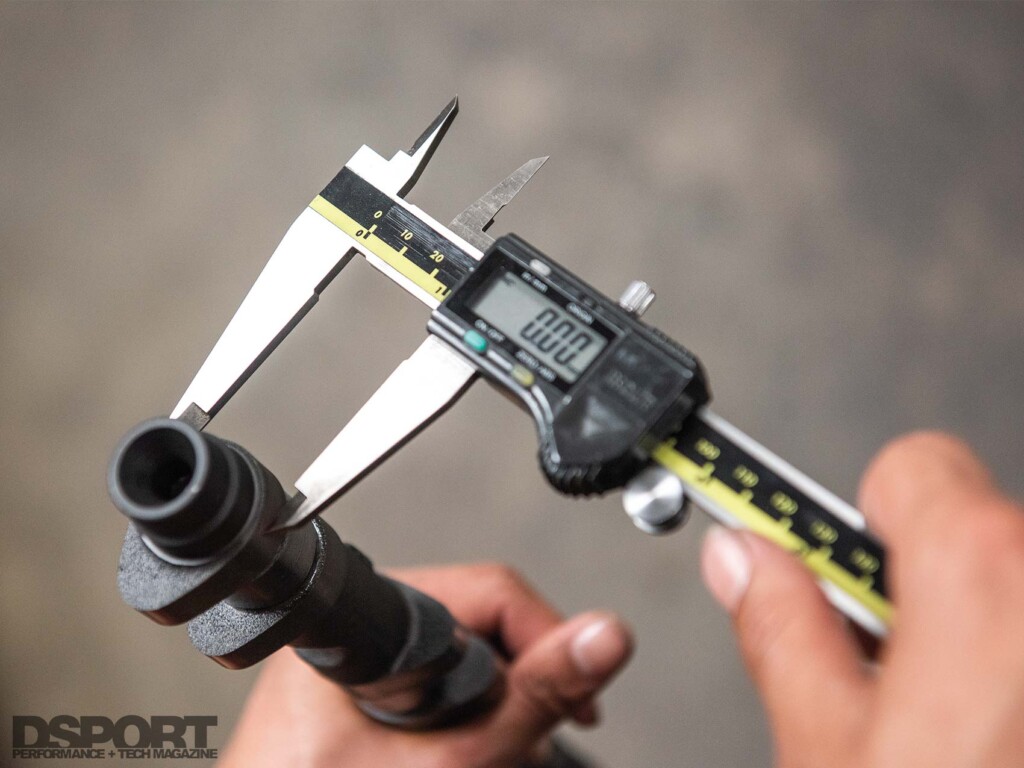

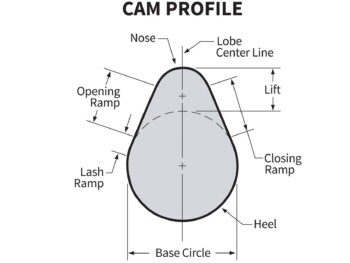

Base Circle (30.0 and 32.0mm)

The OEM RB26 camshafts run a base circle of 32.0mm. Most of the low-lift aftermarket cams for the RB26 also run a base circle of 32.0mm. The base circle of a camshaft represents the diameter of the camshaft if there were no lobe present. A quick measurement can be made by using a set of calipers and measuring the cam across its shortest width. This is sometimes called the heel to heel measurement. Measuring across the widest span, from the heel to the nose, provides the base circle plus lobe lift value. If you measure both the base circle and the base circle plus lobe lift dimensions, the cams peak cam lobe lift can be calculated by the difference between the two measurements.

Nearly all of the high-lift RB26 cams run a smaller 30.0mm base circle. Why? There are a number of reasons. First, the smaller base circle gives a bonus of 1mm of potential additional valve lift without having to increases the height of the nose. As the nose height is increased on the RB26 camshaft, the amount of clearance between the camshaft’s nose and the cylinder head is reduced. Camshafts with lifts over 9.2mm (on a 32mm base circle) need to be checked for adequate clearance between the nose of the cam lobe and the bore where the bucket sits. Camshafts with lifts over 10.2mm (on a 30mm base circle) also need to be checked for adequate clearance between the nose of the cam lobe and the bore where the bucket sits.

When a 30mm base circle cam is used in place of a 32mm base circle cam, 1mm of additional lash will be the result. This must be offset for by either using a thicker lifter/cam follower, thicker shims or by using longer valves. Usually a valve job will reduce the lash about 0.1-to-0.3mm so there is no easy way to predict what shims will be needed to properly set the lash. Due to the amount of time it takes and the parts needed to properly shim an RB26 cylinder head, it is often best to pay the money to have the lash properly set up by the company performing the head work. Expect to pay $400-$600 for this service.

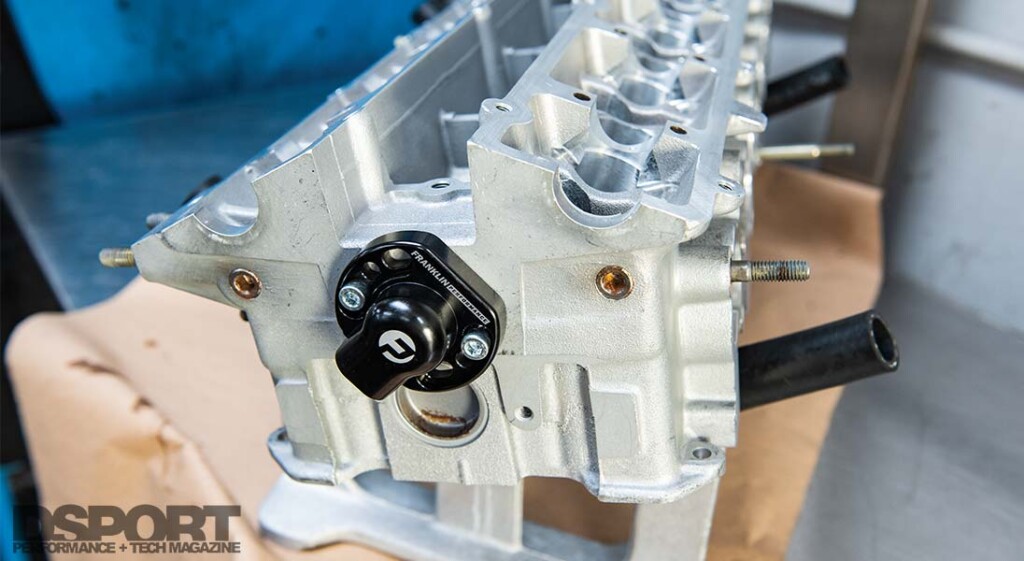

Maximizing oil drainback from the head to the pan should be made a priority on RB26 engines. Adding a drain at the back of the cylinder head can dramatically improve drainback. Get it installed during cylinder head work.

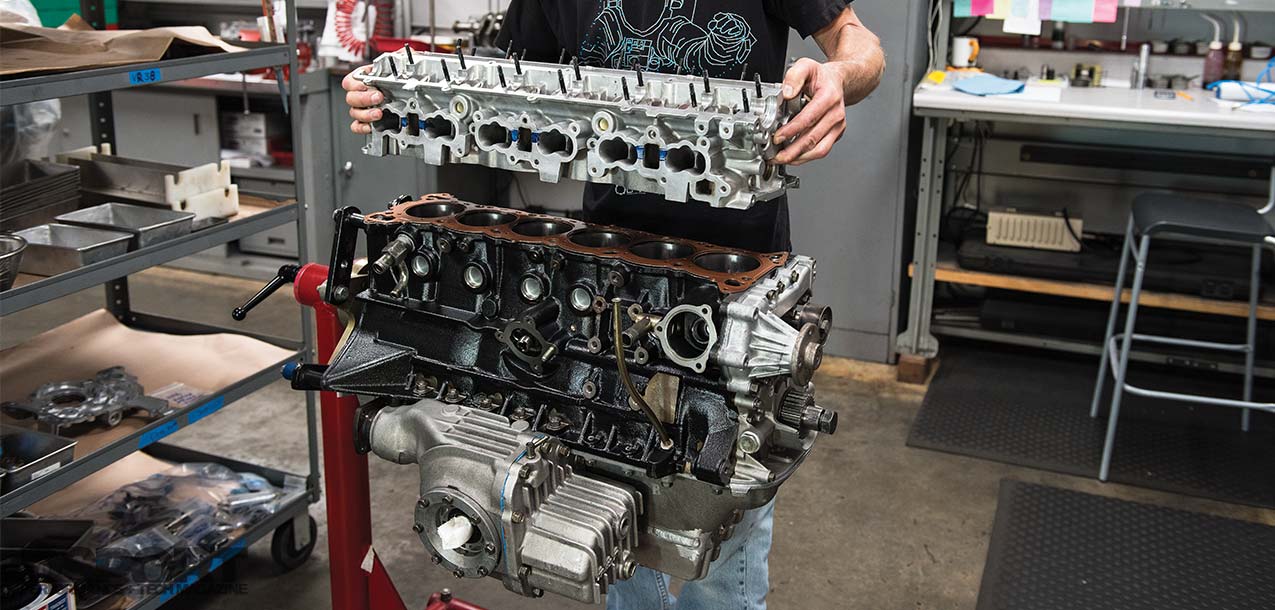

Cylinder Head Overhaul

Every cylinder head is different and knowing what to look for in the disassembly process helps determine what parts need to be replaced. Proper cleaning is a must. Jet washers, solvent tanks and soda blasters are all safe methods for cleaning aluminum cylinder heads. Avoid any blasting of the cylinder head with glass beads, sand or metallic media. Blasting with any of these materials will essentially ruin the cylinder head as some of the blasting media will remain in the cylinder head and eventually be released into the engine’s oiling system. This media will be circulated into the engine’s oiling system and wreak havoc on bearings and piston skirts. While there may be a big temptation to use one of the forbidden blast medias to remove caked on combustion-chamber carbon quickly, don’t do it. Find someone with a soda blaster. Finding used replacement heads is harder than ever and new cylinder heads are nearly impossible to find.

The likelihood of needing to replace the valve guides is almost certain when servicing an RB26 cylinder head. This really isn’t a job for your local machine shop. Extreme care must be exercised and custom tooling should be made to properly remove the original valve guides. When not done properly, the OEM guides will crack apart during removal and damage to the cylinder head’s guide bores can result. If this damage is not addressed (using custom oversized OD valve guides) excessive oil consumption and/or the “dropping” of a valve guide can result. When new guides are installed, the inside bore of the guide must be honed to establish the desired amount of guide to valve stem clearance. Not providing adequate clearance may cause a valve to seize while too much clearance can lead to excessive oil consumption.

If the stems of the OEM valves show significant wear, the valves will need to be replaced. This is a pretty rare situation but we have seen it happen when new guides were installed in the past and the proper guide-to-valve stem clearance wasn’t set. If the stems of the OEM valves are in good shape and the budget doesn’t allow for new valves, reconditioning of the valves can be performed. The reconditioning process restores a precision ground finish and proper geometry to the sealing surface of the valves. The OEM valves are pretty durable and when properly reconditioned can sustain life at power levels of 800whp with proper tuning. The OEM exhaust valves are sodium filled to reduce its weight.

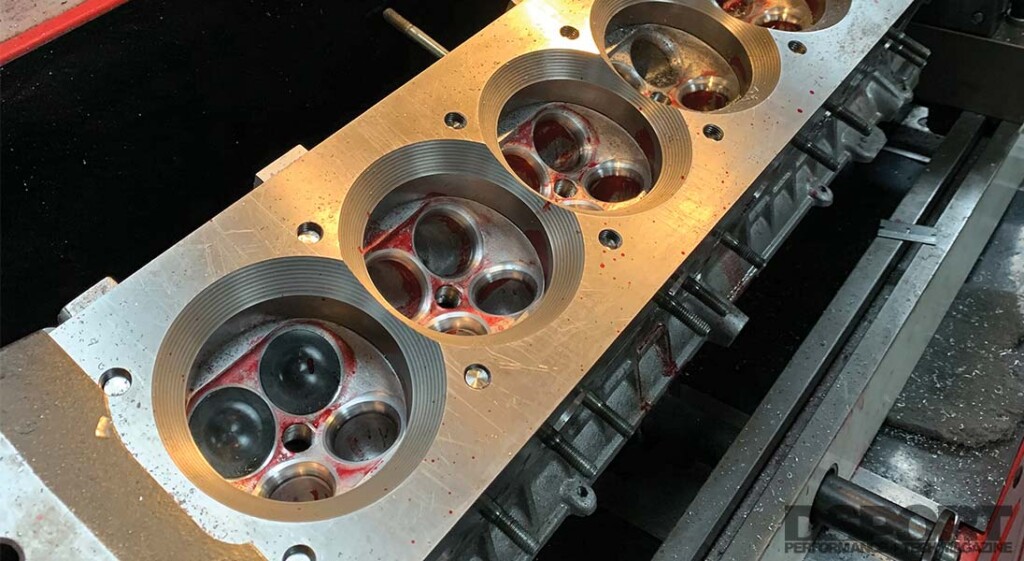

For maximum performance and reliability, the valve job on the RB26 cylinder head should be performed with the head bolted to a torque plate with the same head gaskets and head studs that will be used at the specified torque. This ensures that the valve seat provides the maximum sealing and heat transferring surface.

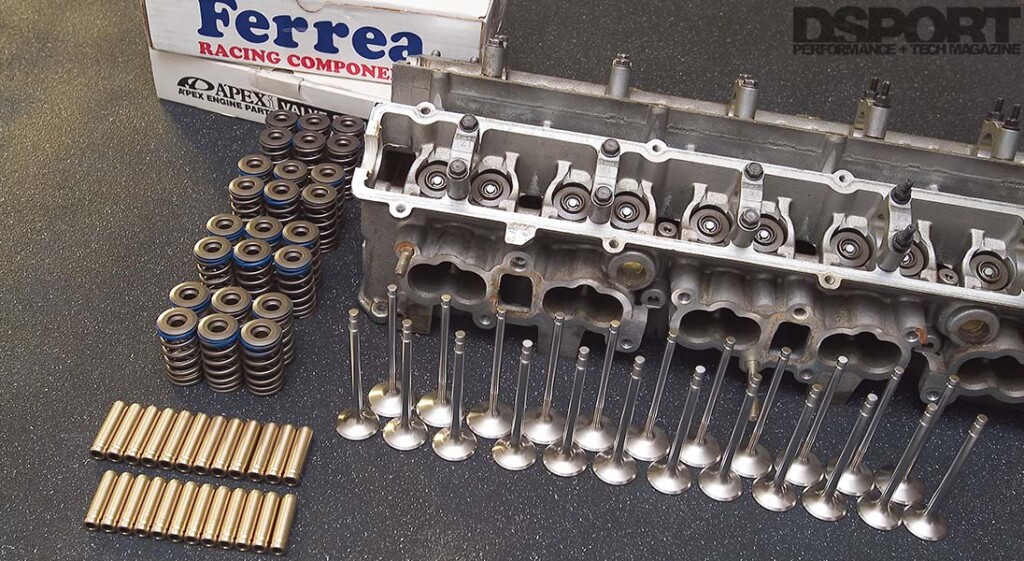

Valve Selection

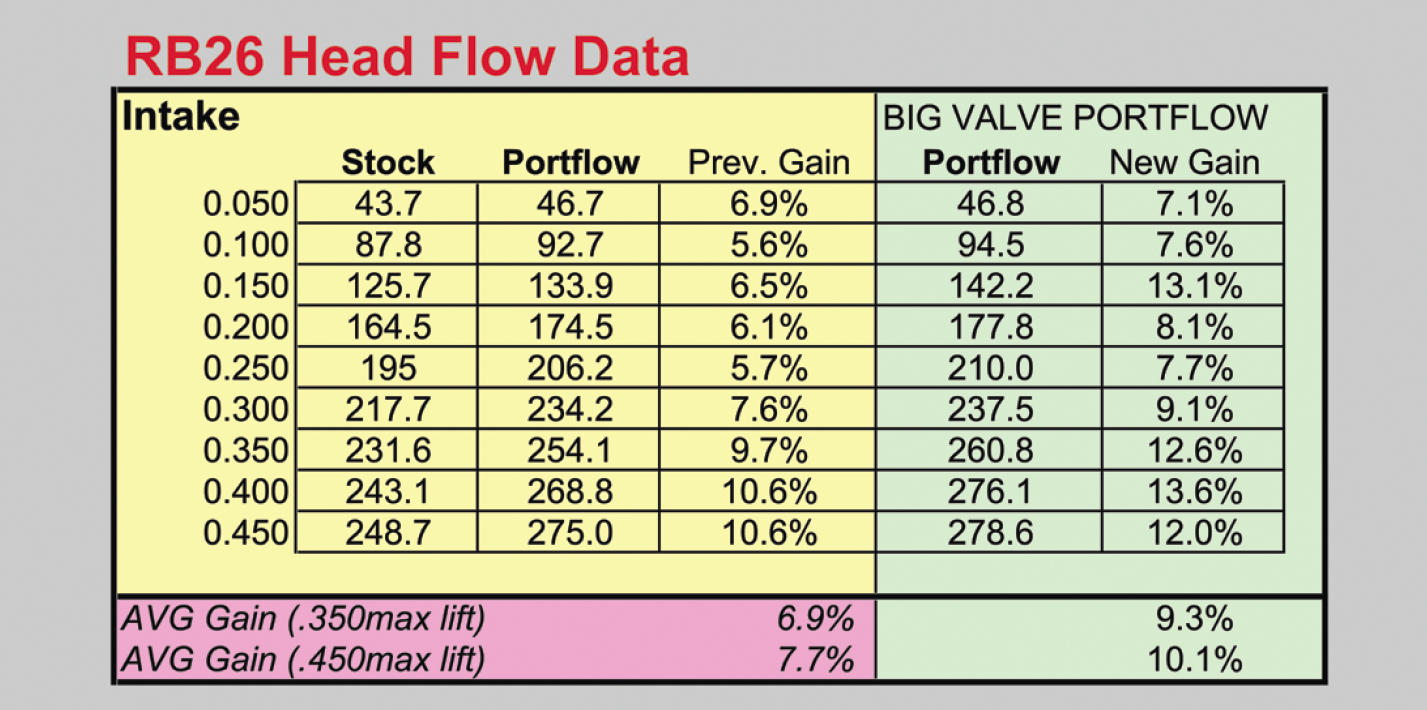

When it comes time to selecting valves for the RB26 cylinder head, there are a number of options. Most manufacturers offer both standard head diameter and a +1mm oversized head diameter valves. If the cylinder head will not be ported or if the porting will be very minimal (pocket porting and match port), the standard diameter valves will actually perform better than oversized valves. More flow and more horsepower will be realized with the stock sized valves in the non-to-mildly-ported cylinder heads. When we tested the +1mm intake valves on a mildly-ported RB26 cylinder head, the flow dropped about 2-percent (5 cfm) compared to the standard size valve. If the porting on the heads is more extensive and optimized for the larger valves, the bigger valves can be a benefit. After reworking the port shapes for the larger valves, the cylinder head delivered numbers about 2-5 percent higher than the standard sized valves. The oversized +1mm valves can also be used to “unsink” the valve position on cylinder heads that have had previous valve jobs that may have sunk the valves deep into the head. This can sometimes be a good fix that save money over replacing 24 valve seats. Some manufacturers also offer extended length high-performance valves. The additional length can be useful in certain configurations that have 30mm base circle cams and/or non OEM cam follower/shim configurations.

When it comes time to selecting valves for the RB26 cylinder head, there are a number of options. Most manufacturers offer both standard head diameter and a +1mm oversized head diameter valves. If the cylinder head will not be ported or if the porting will be very minimal (pocket porting and match port), the standard diameter valves will actually perform better than oversized valves. More flow and more horsepower will be realized with the stock sized valves in the non-to-mildly-ported cylinder heads. When we tested the +1mm intake valves on a mildly-ported RB26 cylinder head, the flow dropped about 2-percent (5 cfm) compared to the standard size valve. If the porting on the heads is more extensive and optimized for the larger valves, the bigger valves can be a benefit. After reworking the port shapes for the larger valves, the cylinder head delivered numbers about 2-5 percent higher than the standard sized valves. The oversized +1mm valves can also be used to “unsink” the valve position on cylinder heads that have had previous valve jobs that may have sunk the valves deep into the head. This can sometimes be a good fix that save money over replacing 24 valve seats. Some manufacturers also offer extended length high-performance valves. The additional length can be useful in certain configurations that have 30mm base circle cams and/or non OEM cam follower/shim configurations.

Besides options for the head diameter and overall valve length, some manufacturers may also offer a selection of valve materials. Most intake valves will be offered in a high-performance stainless-steel while there may be multiple options for the exhaust valve ranging from stainless-steel to Inconel to sodium-filled. Exhaust valves are subject to extreme temperatures and a good deal of abuse. Only stainless-steel alloys specifically manufactured for exhaust valve use should be considered. The “go-to” material for exhaust valves on high-performance turbocharged engines is Inconel or similar high-performance nickel-based alloys. These Inconel alloys have tensile strengths that can be significantly higher than stainless steel at operating temperatures. There are also sodium-filled Inconel exhaust valves available for the RB26. These valves have a drilled stem that has been filled with sodium. The sodium-filling provides two benefits. First, it reduces the valve weight about 10 percent. Second, the sodium helps accelerate the heat transfer from the head to the rest of the valve. As a result, the heads will run cooler making pre-ignition a less-likely occurrence. When running sodium-filled valves, it is important to run the proper amount of valve stem to guide clearance.

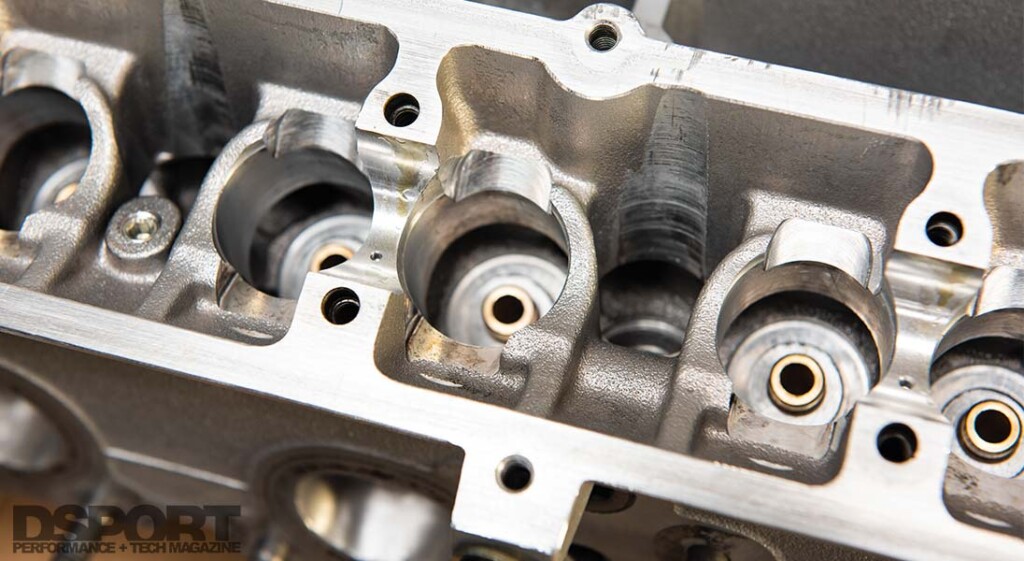

This valve job was cut on a Newen CNC valve seat cutter. This machine allows for the custom valve jobs optimized for the application with just a few keystrokes.

Proper Porting

In our November 2004 issue, we looked to the flow bench for some answers with regard to cylinder head flow. At that time, the question was simple: “How much additional cylinder-head flow could we realize through porting with the factory-sized valves in place?” The results were pretty impressive. On the intake ports, we were able to increase the peak flow figures by 10.6 percent, while the average flow increase across the spectrum of varied lifts was about seven percent. On the exhaust ports, the increase was even more impressive. Peak flow increased by 22.2 percent. At the same time, the average flow increase across the spectrum of varied lifts was roughly 15 percent. The bottom line was that the ported cylinder head and A’PEX low-lift camshafts allowed over 120 additional horsepower to be realized at the wheels.

In our November 2004 issue, we looked to the flow bench for some answers with regard to cylinder head flow. At that time, the question was simple: “How much additional cylinder-head flow could we realize through porting with the factory-sized valves in place?” The results were pretty impressive. On the intake ports, we were able to increase the peak flow figures by 10.6 percent, while the average flow increase across the spectrum of varied lifts was about seven percent. On the exhaust ports, the increase was even more impressive. Peak flow increased by 22.2 percent. At the same time, the average flow increase across the spectrum of varied lifts was roughly 15 percent. The bottom line was that the ported cylinder head and A’PEX low-lift camshafts allowed over 120 additional horsepower to be realized at the wheels.

While the RB26 cylinder head flows respectively in stock form, proper porting of the cylinder heads can significantly improve performance. Before launching Club DSPORT, the majority of the cylinder work done for project builds was done by Tom Fujita of Port Flow Design of Harbor City, California. Tom’s porting philosophy centered upon reshaping the port to optimize its efficiency rather than making it as big as possible. At Club DSPORT, we share that philosophy today and focus on porting that gives us the biggest gains in flow with the minimal increases in port area. The end results are ports that use velocity and momentum to maximize cylinder filling. While bigger ports may be able to deliver better performance on the flow bench, the ports that win the battle on the dyno and the track are what win the races. As for the CNC porting available in the market, we have seen varied results. We’ve either seen ports that are simply a cleanup of the OEM port or ports that have been made so big that velocity is killed. CNC porting of a cylinder head is only as good as the port design being machined into the head. Even the best CNC porting done today requires some amount of hand work to finish the ports for maximum performance. If demand continues to grow for Club DSPORT RB26 cylinder heads, there may be an option featuring a hand-blended CNC machined port in the future. Until then, all Club DSPORT porting will be done by skilled hands.

Speed Bumps

When the exhaust ports of RB26 cylinder heads are ported, there is always much focus on the “speed bumps” in the exhaust ports. An article appearing in a Japanese performance magazine nearly 20 years ago spoke about significant gains from the removal of these speed bumps. We decided to put the claims to the test shortly after the article was published. Did the removal of the “speed bump” significantly increase exhaust flow? Between .100- to .300-inch of valve lift, the removal of the speed bump, in fact, adversely affected flow. At higher valve lifts from .350-inch to .450-inch, the larger exhaust port with no speed bumps had superior flow. All in all, we picked up about three percent in peak flow compared to the previous “speed bump” head. However, the average flow improvement was a less impressive one percent. On a properly-ported cylinder head there is only a one-percent gain from the removal of the speed bump with factory-sized exhaust valves. Considering that there is a good likelihood for someone unfamiliar with the RB26 cylinder head to break into the coolant jacket when trying to remove the speed bumps, DO NOT attempt to remove the speed bumps. If you are going with oversized valves and you need a fully-developed exhaust port, rely on someone very familiar with the RB26 cylinder heads to remove the speed bumps. Otherwise, there will end up being one less usable RB26 cylinder head in the world.

11,000RPM+

When running our 2.6-liter RB combination in our R33 GT-R, we would often visit the land of 10,000RPM. This was done with a special setup using the currently available spring, retainer and cam follower packages. In the 20 years of racing the RB26 engine, we would only encounter one valvetrain failure. The failure occurred while the engine was on the 2-step for an extended period. During this failure, the OEM shim got sideways holding the valve open and initiating contact with the piston. Now that showing off your two-step and having a pops-and-bang display has become common, we decided to come up with a shimless bucket conversion for the RB26. Our first design is already a success at the races while we are finishing up our second design which moves to a conical spring. With the Club DSPORT shimless conversion on the RB26 cylinder head, 11.000RPM is achievable. Just make sure the bottom end of the engine is properly built for such endeavors.

When running our 2.6-liter RB combination in our R33 GT-R, we would often visit the land of 10,000RPM. This was done with a special setup using the currently available spring, retainer and cam follower packages. In the 20 years of racing the RB26 engine, we would only encounter one valvetrain failure. The failure occurred while the engine was on the 2-step for an extended period. During this failure, the OEM shim got sideways holding the valve open and initiating contact with the piston. Now that showing off your two-step and having a pops-and-bang display has become common, we decided to come up with a shimless bucket conversion for the RB26. Our first design is already a success at the races while we are finishing up our second design which moves to a conical spring. With the Club DSPORT shimless conversion on the RB26 cylinder head, 11.000RPM is achievable. Just make sure the bottom end of the engine is properly built for such endeavors.

The Bottom Line

The RB26 has a great cylinder head in terms of what was offered during its production era. Compared to the 2JZ cylinder head, it has superior ports, symmetrical exhaust ports (no dog leg), shim-under-bucket valvetrain and the ability to remove the head with the cams still in place. With the right mix of parts and modifications, a properly modified RB26 cylinder head and cam package can deliver over 40-percent more horsepower over the OEM cylinder head and cams. While the cost of properly building the RB26 cylinder head can sometimes exceed the cost of building the short block, it can be money well spent. Power goals will be realized at lower boost pressure levels and the possibility of valvetrain failure can be virtually eliminated. In part two, we will go over some of the proven Club DSPORT cylinder head performance combinations and the associated costs to go fast. Stay tuned.