Getting Wasted

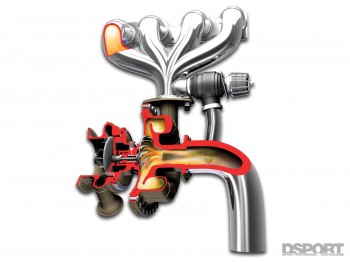

Regardless if it is an integral (internal) or external design, a wastegate diverts a portion of the engine’s pre-turbo exhaust flow away from the turbine section of the turbocharger. This diversion of exhaust gasses away from the turbine prohibits the turbo from increasing its shaft speed to build more boost pressure. All wastegates rely upon a reference/signal pressure from the intake manifold to know when to start and stop the “waste gating” effect. It is this signal that is manipulated by the electronically-controlled boost solenoid that allows different boost levels to be achieved with an external wastegate or actuator that is set at a specific spring pressure and preload. Hence, achieving 10, 20 or 50 psi of boost pressure on a wastegate rated to deliver 10 psi of boost pressure is possible.

Regardless if it is an integral (internal) or external design, a wastegate diverts a portion of the engine’s pre-turbo exhaust flow away from the turbine section of the turbocharger. This diversion of exhaust gasses away from the turbine prohibits the turbo from increasing its shaft speed to build more boost pressure. All wastegates rely upon a reference/signal pressure from the intake manifold to know when to start and stop the “waste gating” effect. It is this signal that is manipulated by the electronically-controlled boost solenoid that allows different boost levels to be achieved with an external wastegate or actuator that is set at a specific spring pressure and preload. Hence, achieving 10, 20 or 50 psi of boost pressure on a wastegate rated to deliver 10 psi of boost pressure is possible.

Integral or External

Nearly all factory turbochargers and even some performance aftermarket turbochargers use a wastegate that is integrated within the turbine housing. A flapper valve hooked up to a single- or dual-port actuator comprises the integral wastegate. For racing and high-performance applications, one or more external wastegates are often employed. An external wastegate has both the actuating and valve portion in the same body, and all external wastegates feature dual ports. On dual-port wastegates, one port allows a reference pressure signal to be sent to the top side of the diaphragm, while the other port sends the signal to the bottom side of the diaphragm.

Getting a Lift

The difference in pressure between the top and bottom side of the wastegate’s diaphragm generates a force that will try to either lift or close the valve. When maximum boost limiting is desired, the full amount of the boost signal is applied to the bottom port under the diaphragm, while the top port sees no gauge pressure (atmospheric pressure only). This creates the maximum amount of lifting force possible. This force is used to overcome the seat pressure set by the spring utilized in the wastegate. As boost pressure rises, more lifting force is created until this lifting force exceeds the preloaded spring-seat pressure. As a result, the wastegate’s valve lifts, and exhaust flow is diverted away from the turbine to reduce shaft speeds and boost pressure.