WARNING: Upgrading from a two- or three-port boost control solenoid to a three- or four-port solenoid will require lower boost control solenoid duty cycle settings or overboost will occur.

The Three-Port Solenoid

The Three-Port Solenoid

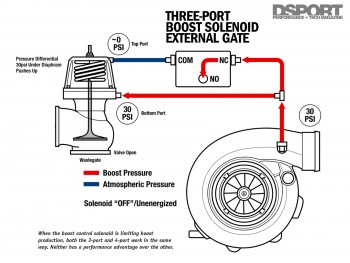

The most basic wastegated turbocharger system simply runs a boost reference signal hose to the bottom port of an external wastegate or to the only port on a single-port actuator. This elementary system has been replaced by modern systems that incorporate a three-port solenoid along with a single- or dual-port actuator or wastegate. When the solenoid is not energized, or if it fails in the closed position, the wastegate or actuator will behave just like the elementary system, having a boost pressure signal fed to the bottom port to lift the wastegate valve at the spring-determined boost pressure.

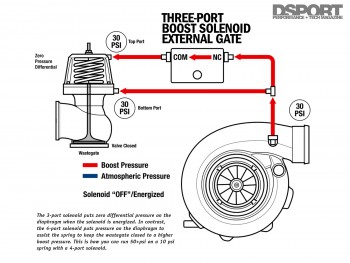

When the three-port solenoid is energized (under the control of the ECU or aftermarket boost controller), the signal line routing allows the pressure to both the top and bottom of the diaphragm to equalize. Hence, it has the same effect as disconnecting the boost line to the wastegate (which equalizes pressure on the top and bottom of the diaphragm). Boost pressure then rises beyond the level dictated by the spring.

When the three-port solenoid is energized (under the control of the ECU or aftermarket boost controller), the signal line routing allows the pressure to both the top and bottom of the diaphragm to equalize. Hence, it has the same effect as disconnecting the boost line to the wastegate (which equalizes pressure on the top and bottom of the diaphragm). Boost pressure then rises beyond the level dictated by the spring.

The Four-Port Solenoids

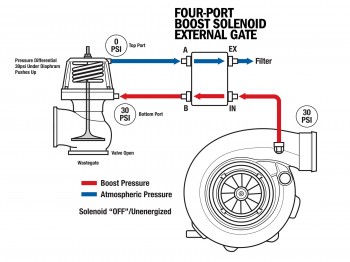

If you are running a turbocharger system that incorporates dual-port wastegates or dual-port actuators, a four-port boost-control solenoid will provide the ultimate in boost performance. Typically, a four -port solenoid will allow boost control from a range of the wastegate/actuator boost pressure rating up to a value that is four to six times that rating. Hence, a setup using a 10-psi wastegate spring could be controlled to deliver 10 to 50-plus psi when a four -port solenoid is used. This makes the four -port solenoid a great solution on high-powered FWD applications. With the proper controller for the solenoid, the boost level can be set low enough to limit wheel spin at lower speeds and cranked up to higher levels to maximize traction at higher speeds. We employ this strategy on our DSPORT Project FAME Civic. Controlled by the MoTeC M800 engine management system, it runs 10 psi of boost pressure on the launch and ramps up the pressure based on vehicle speed. In addition to doubling or tripling the boost range over a three-port solenoid, a four-port solenoid also delivers other advantages.

If you are running a turbocharger system that incorporates dual-port wastegates or dual-port actuators, a four-port boost-control solenoid will provide the ultimate in boost performance. Typically, a four -port solenoid will allow boost control from a range of the wastegate/actuator boost pressure rating up to a value that is four to six times that rating. Hence, a setup using a 10-psi wastegate spring could be controlled to deliver 10 to 50-plus psi when a four -port solenoid is used. This makes the four -port solenoid a great solution on high-powered FWD applications. With the proper controller for the solenoid, the boost level can be set low enough to limit wheel spin at lower speeds and cranked up to higher levels to maximize traction at higher speeds. We employ this strategy on our DSPORT Project FAME Civic. Controlled by the MoTeC M800 engine management system, it runs 10 psi of boost pressure on the launch and ramps up the pressure based on vehicle speed. In addition to doubling or tripling the boost range over a three-port solenoid, a four-port solenoid also delivers other advantages.

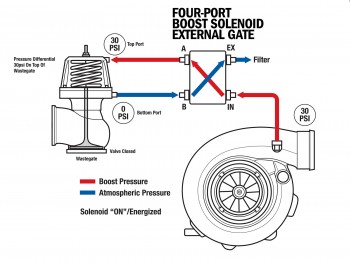

For those looking to maximize boost response, the four-port solenoid can be controlled to deliver pressure to the top wastegate port while the boost pressure is ramping up. This additional pressure on the top of the diaphragm helps to keep the wastegate or actuator from lifting its valve to bleed off pre-turbine exhaust. In practice, we found that the four-port solenoid can actually be set so that boost response is so aggressive that compressor surge is encountered. We had never run into that issue before, but our recent tuning session with the RB26DETT engine in our Project RH9 GT-R showed this exact effect. We were able to get the boost pressure higher than the surge limit of the turbocharger for the given amount of horsepower. Of course, simply reducing the duty cycle of the solenoid to a slightly lower duty cycle allowed us to avoid compressor surge.

For those looking to maximize boost response, the four-port solenoid can be controlled to deliver pressure to the top wastegate port while the boost pressure is ramping up. This additional pressure on the top of the diaphragm helps to keep the wastegate or actuator from lifting its valve to bleed off pre-turbine exhaust. In practice, we found that the four-port solenoid can actually be set so that boost response is so aggressive that compressor surge is encountered. We had never run into that issue before, but our recent tuning session with the RB26DETT engine in our Project RH9 GT-R showed this exact effect. We were able to get the boost pressure higher than the surge limit of the turbocharger for the given amount of horsepower. Of course, simply reducing the duty cycle of the solenoid to a slightly lower duty cycle allowed us to avoid compressor surge.

For those looking for maximum control of the boost curve, the four-port delivers. Since the duty cycle percentages are drastically reduced (when compared to a three-port solenoid), there is a larger amount of headroom for control.

For those looking to get maximum boost pressure from a particular turbocharger, the four-port fits the bill. Being able to put boost pressure to the top of the diaphragm, while the bottom of the diaphragm sees only atmospheric pressure, adds pressure to the valve to keep it closed until it experiences a higher boost pressure.